Resin composition, molded article, and electrical wire

A resin composition, polyphenylene ether resin technology, applied in synthetic resin layered products, plastic/resin/wax insulators, circuits, etc., can solve the problems of low water absorption, poor impact resistance, etc., and achieve the effect of inhibiting whitening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

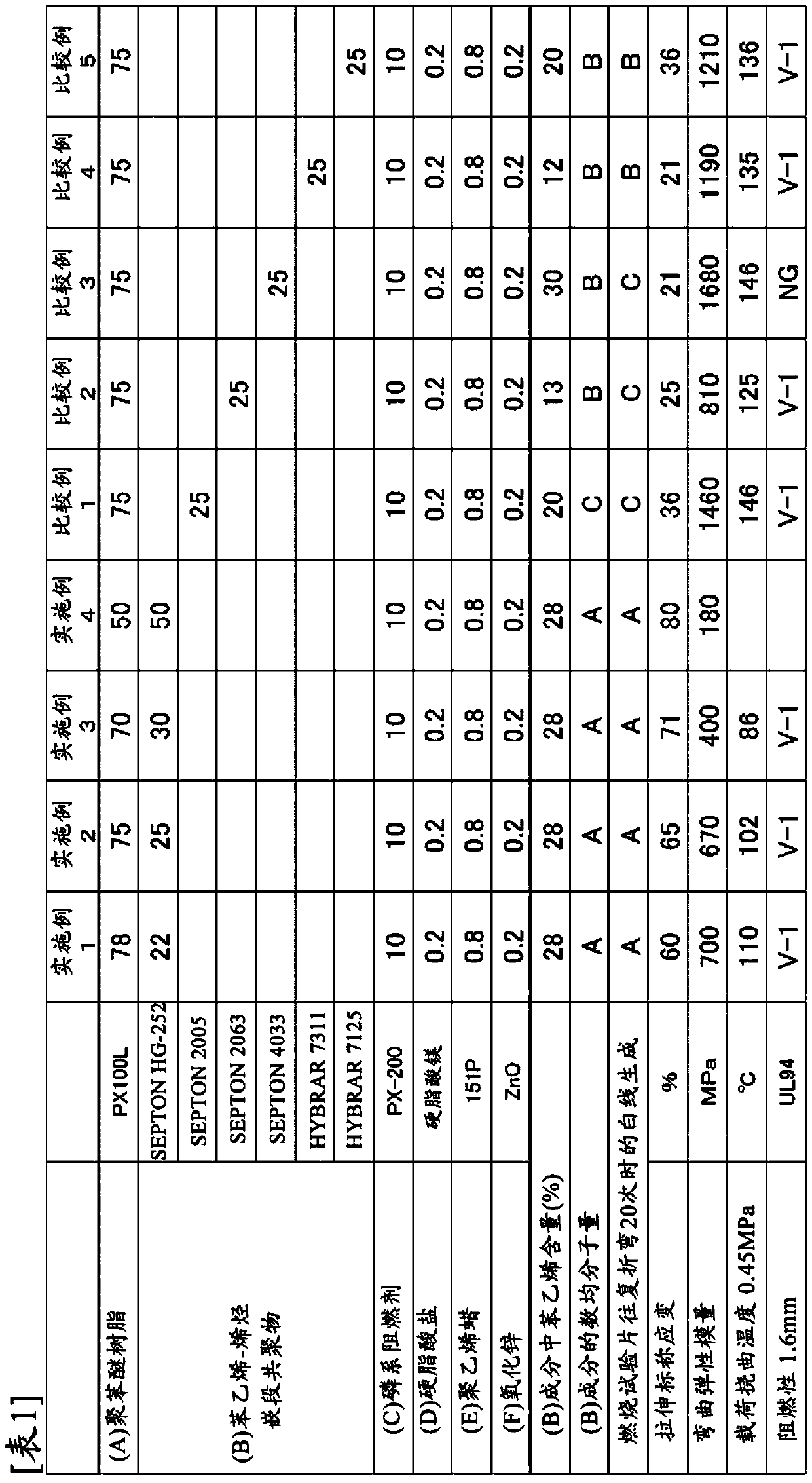

Embodiment 1~4、 comparative example 1~5

[0127] The components were mixed according to the ratio (mass basis) shown in the following Table 1, and melt kneaded at a cylinder temperature of 280°C and a screw speed of 350 rpm using a twin-screw extruder (manufactured by Toshiba Machine Co., Ltd.: TEM18SS) , and a resin composition (pellet) was obtained.

[0128] Table 1 shows the results of the following evaluations performed using the obtained resin composition (pellets).

[0129]

[0130] (B) The number average molecular weight of the styrene-olefin block copolymer is as follows.

[0131] A: Less than 100,000

[0132] B: More than 100,000 and less than 200,000

[0133] C: More than 200,000

[0134]

[0135] The resin composition (pellet) obtained above was dried at 70°C for 3 hours, and then, using an injection molding machine (manufactured by Toshiba Machine Co., Ltd., "EC75SX"), it was molded at a cylinder temperature of 270°C and a mold temperature of 60°C. The UL94 combustion test piece of 127mm*12.7mm*1.6m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com