Ultrasonic vibrator mounting structure of dish washing machine

An installation structure and ultrasonic technology, applied in the washing machine/washing machine of tableware, parts of washing machine/rinsing washing machine for tableware, household cleaning device, etc., can solve the problems of high cost, water leakage, aging sealing ring, etc. The effect of safety in use, simple installation structure, and avoiding the risk of water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following examples illustrate the invention, but the invention is not limited by these examples. Modifications to the specific implementation of the present invention or equivalent replacement of some technical features without departing from the spirit of the present invention should be included in the scope of the technical solution claimed in the present invention.

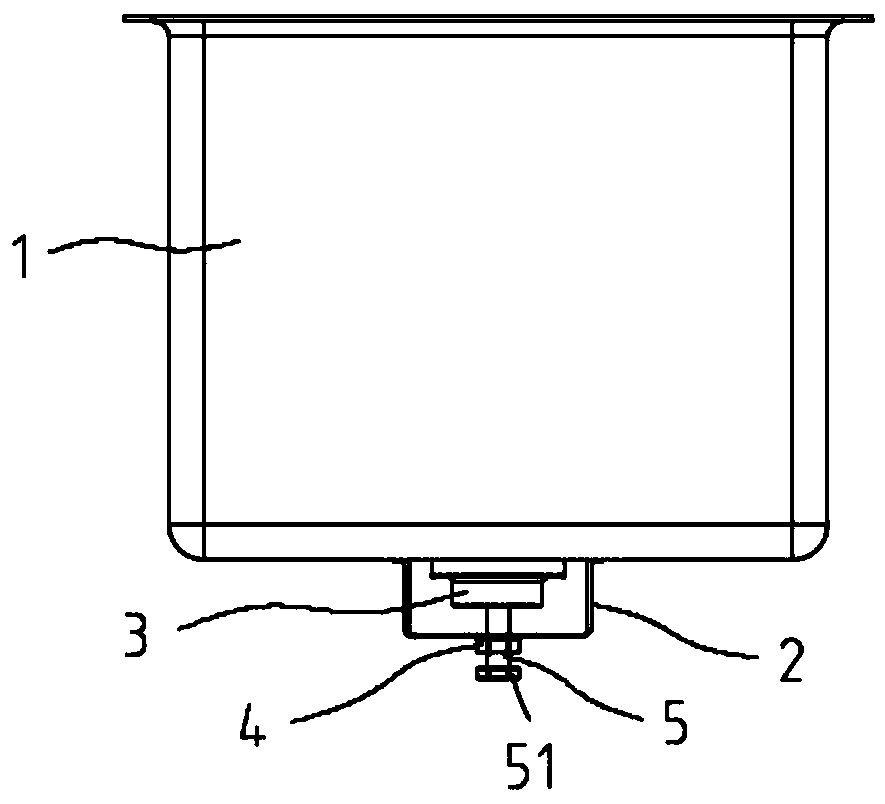

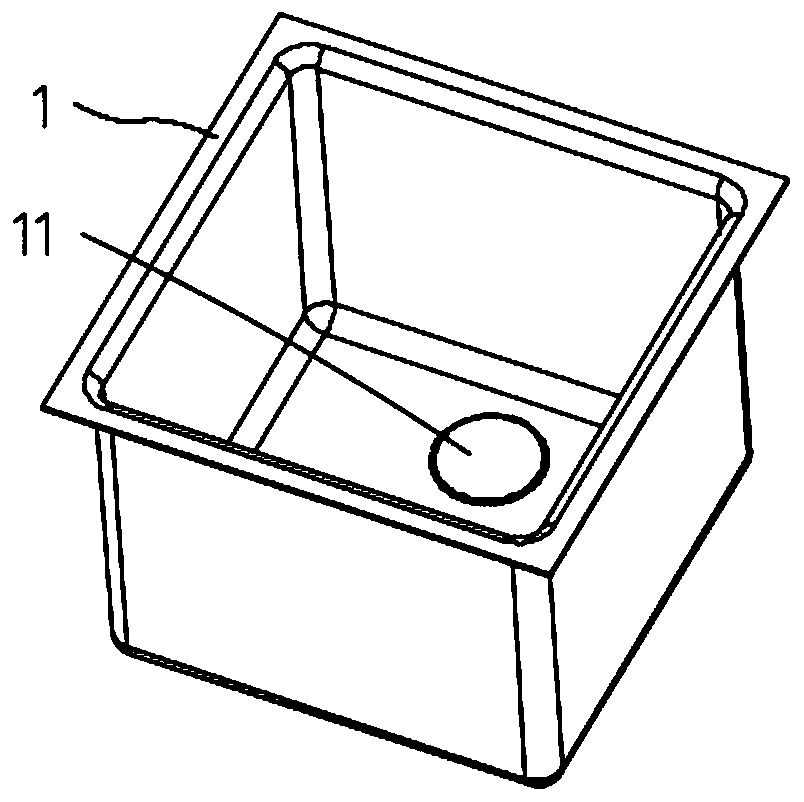

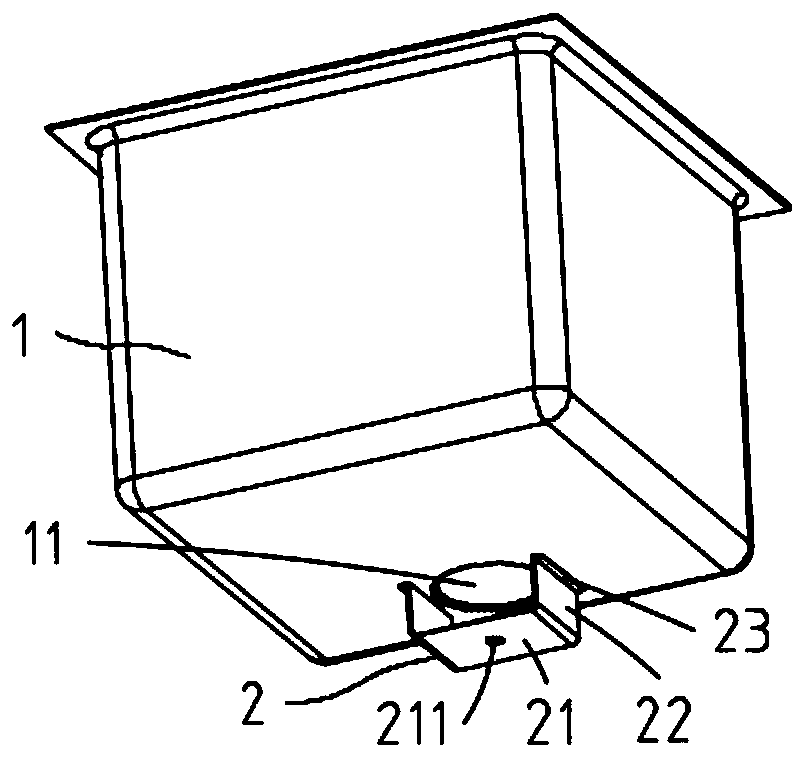

[0023] Such as Figure 1-4 As shown, the ultrasonic vibrator installation structure of a dishwasher in this embodiment includes an inner tank 1, a fixed bracket 2 and an ultrasonic vibrator 3, the fixed bracket 2 is arranged under the bottom of the inner tank 1 and is fixedly connected with the inner tank 1, The ultrasonic vibrator 3 is arranged on the fixed bracket 2 , and the vibrating surface at the top of the ultrasonic vibrator 3 is in close contact with the outer surface of the bottom of the liner 1 .

[0024] It can be seen that in the installation structure of the ultrasonic vibrator in this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com