Automatic down lamp assembling equipment

An assembly equipment and automatic assembly technology, applied in assembly machines, metal processing equipment, positioning devices, etc., can solve problems such as large demand, inability to ensure consistent production volume, worker injury, etc., to improve production efficiency and high practicability And the effect of promoting value and reasonable structure layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

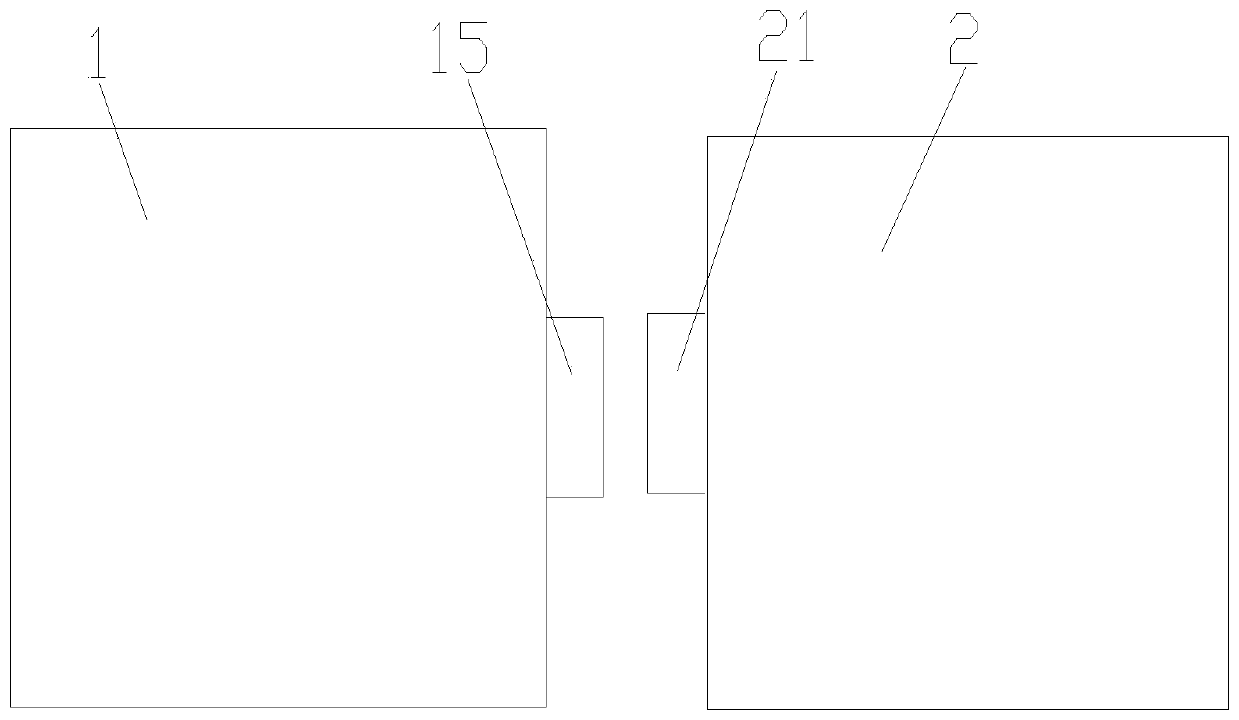

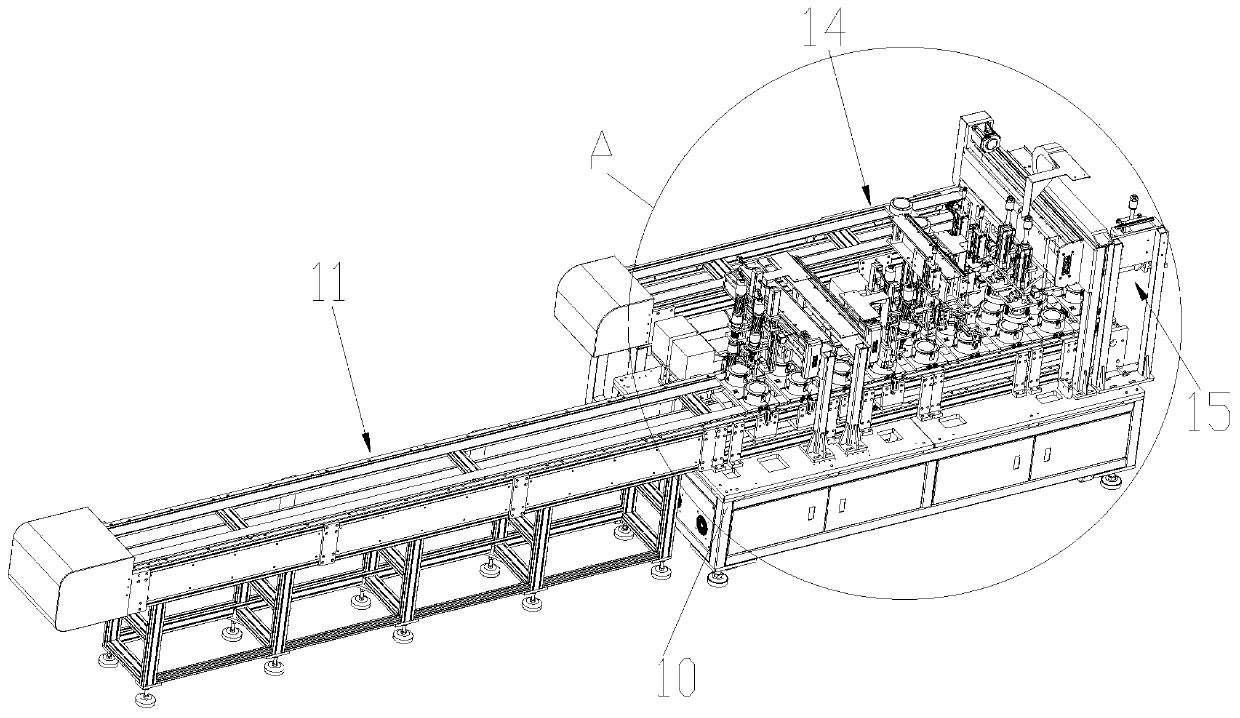

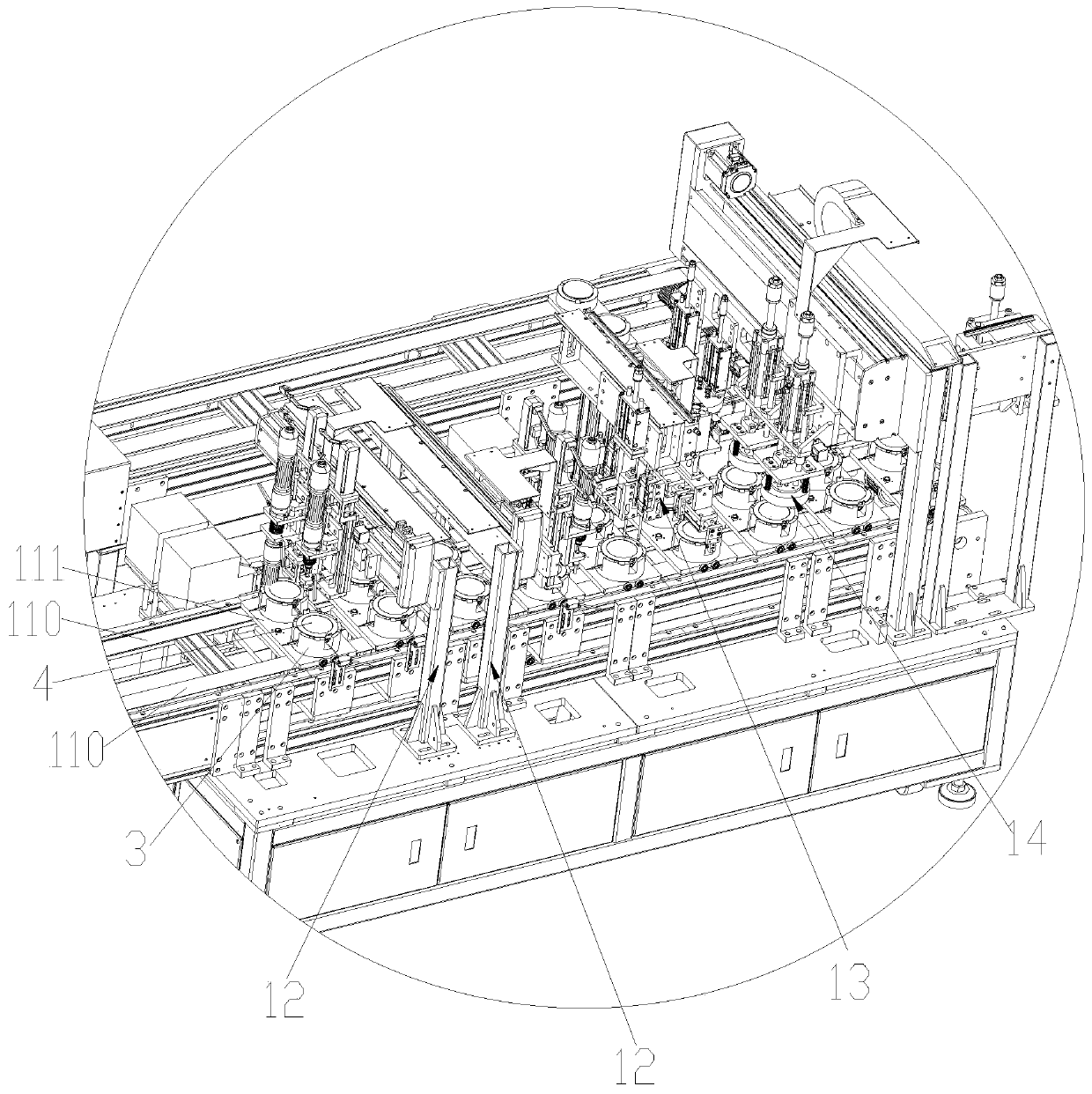

[0053] Please refer to the attached Figure 1-17 , a downlight assembly device according to the present invention, comprising: a downlight front assembly device 1 and a downlight back assembly device 2 arranged oppositely; wherein, the downlight front assembly device 1 is used to install the lamp body and the diffuser plate to the lamp body; assemble the equipment 2 on the reverse side of the downlight, which is used to install the buckle, left circlip, and right circlip on the lamp body.

[0054] Specifically, the downlight front assembly equipment 1 includes an assembly line indexing fixture 11 arranged on the front frame 10, which is used to drive the lamp board and the lamp body to be forwarded synchronously and processed sequentially; two sets of symmetrically arranged screws Automatic assembly equipment 12, each set of screw au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com