Packing machine

A packing machine and chassis technology, which is applied in the field of packing machines, can solve the problems of large footprint, wide area, unsuitable for packing small bottles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

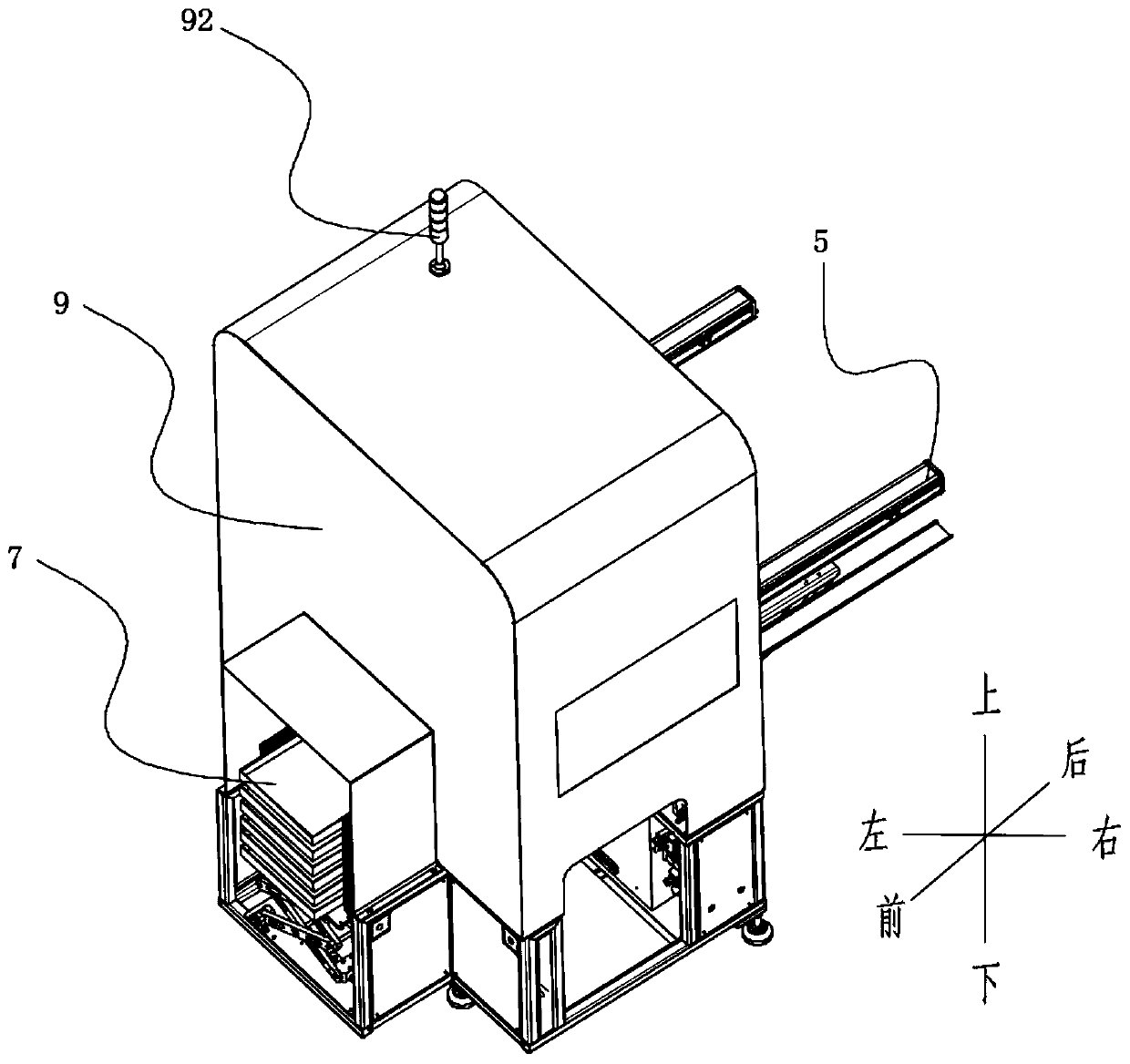

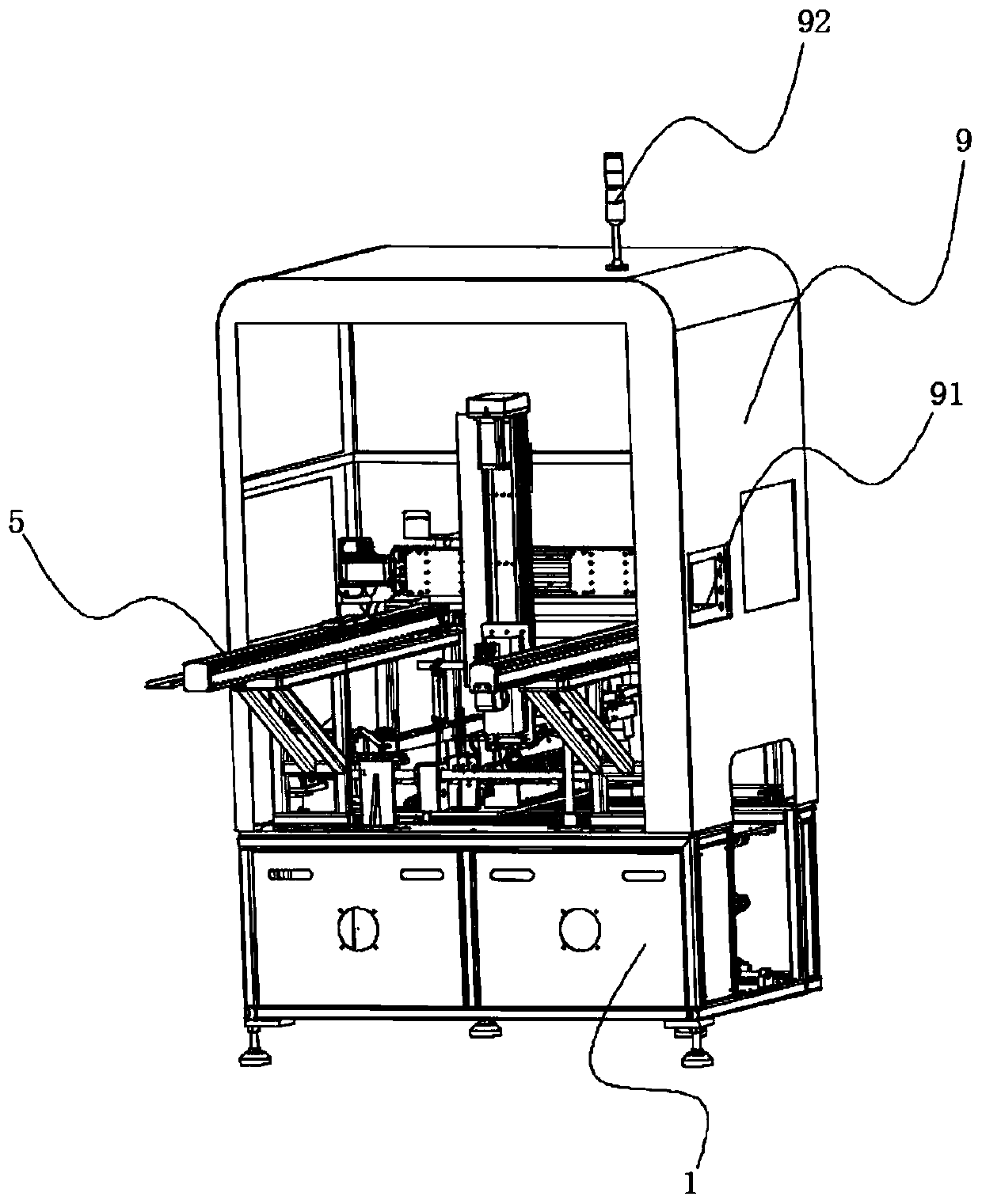

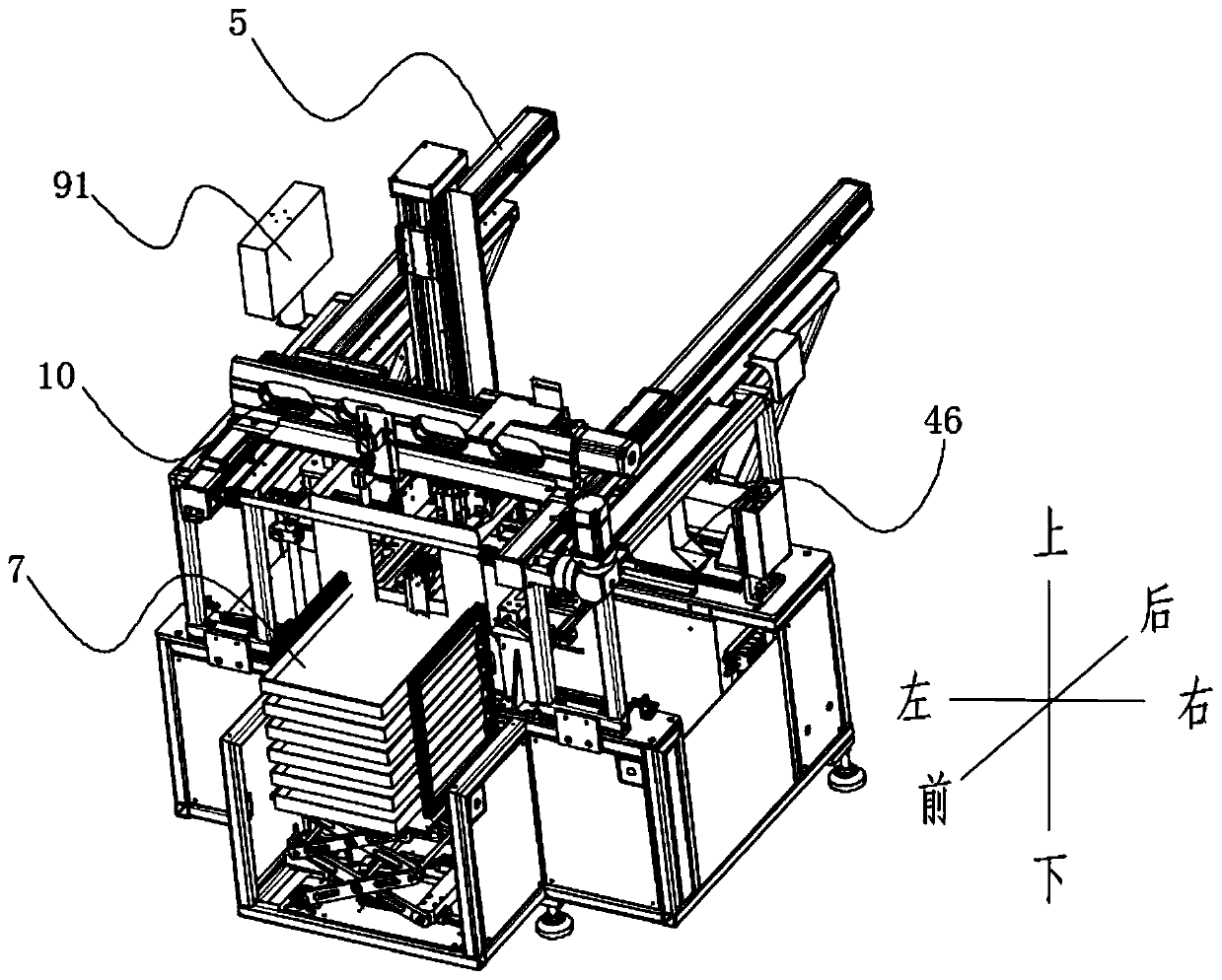

[0044] Such as Figures 1 to 5 As shown, a packing machine includes a frame 1, and the frame 1 includes a first cabinet 11a and a second cabinet 11b arranged in parallel at intervals, so that a vacant area 12 is formed between the first cabinet 11a and the second cabinet 11b; A mobile device 2 is erected between the first cabinet 11a and the second cabinet 11b; the mobile device is located directly above the vacant area; the left side of the mobile device 2 is provided with a discharge device 3, and the right side is provided with a positioning device 4; the first cabinet The front side of 11a is provided with a feeding device 7; the feeding device 7 is arranged in the feeding area 14 of the front side of the first cabinet 11a; the feeding area 14 passes through the first cabinet 11a and communicates with the vacant area 12; the first cabinet 11a and the left and right sides of the second chassis 11b are respectively erected with a bracket 13; the bracket 13 is provided with a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap