Preparation method for Al-Si-Mn-Fe-Ga high-entropy decagonal quasicrystal

A technology of al-si-mn-fe-ga, al20si20mn20fe20ga20, which is applied in the field of preparing Al-Si-Mn-Fe-Ga high-entropy ten-order quasicrystal, and achieves the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1)Al 20 Si 20 mn 20 Fe 20 Ga 20 Preparation of High Entropy Alloy Flakes

[0031] First, the metal Al (99.99%), Si (99.99%), Mn (99.99%), Fe (99.99%), Ga (99.99%), according to the atomic ratio of 20:20:20:20:20 ingredients, select vacuum Melting in an induction melting furnace with a rated temperature of 1700°C to obtain Al 20 Si 20 mn 20 Fe 20 Ga 20 High-entropy alloy ingot 2Kg.

[0032] 2) Take a small amount of smelted Al 20 Si 20 mn 20 Fe 20 Ga 20 High-entropy alloy ingots, smashed into small pieces with a diameter of about 1cm.

[0033] 3) Take 70 g of the massive high-entropy alloy with a diameter of about 1 cm prepared in step 2), and use a vacuum strip-spinning machine to prepare a rapidly solidified strip-spin sheet at a roll speed of 25 m / s. High-entropy decaquasicrystals were obtained.

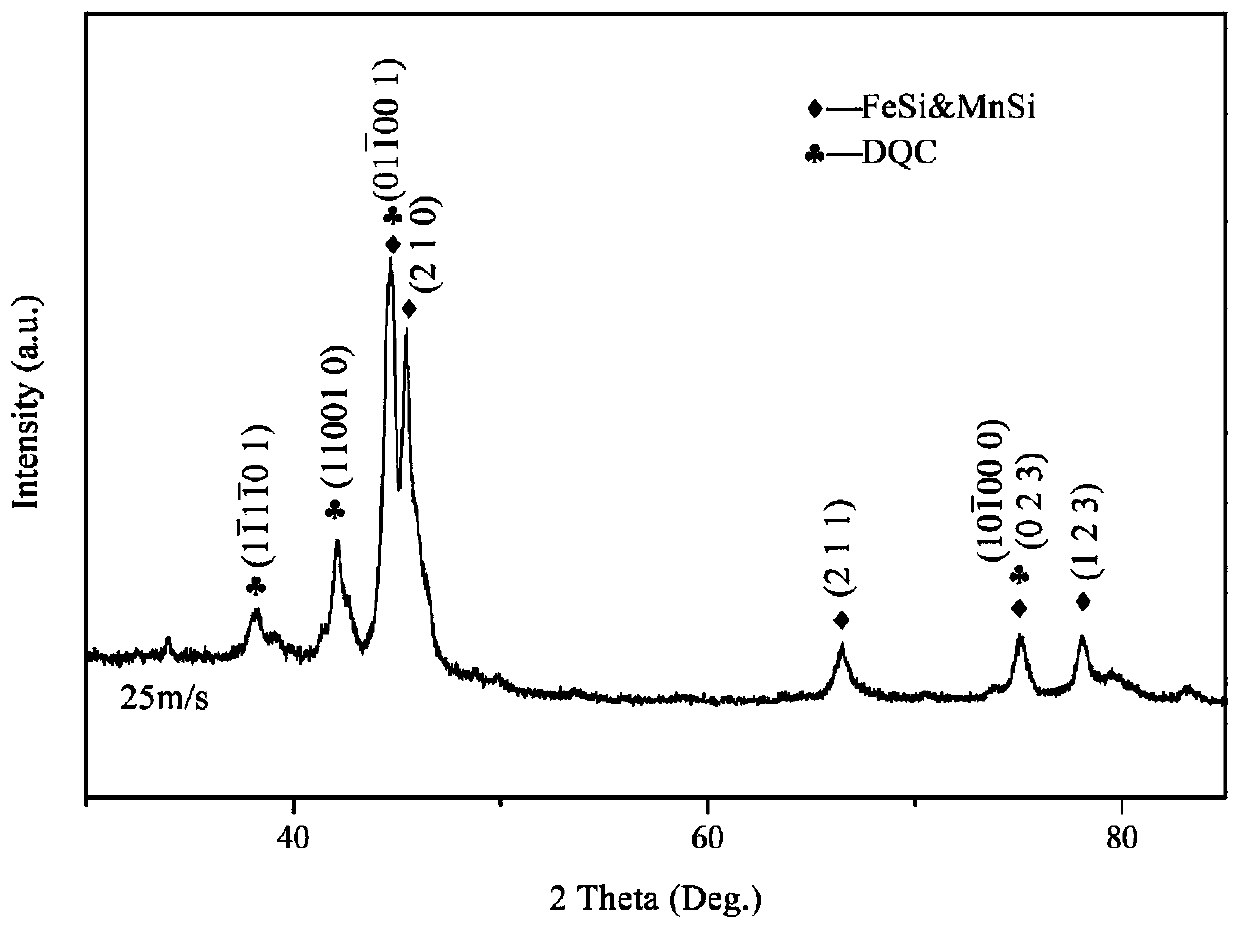

[0034] According to 3) the Al prepared by the method described 20 Si 20 mn 20 Fe 20 Ga 20 XRD pattern of high entropy alloy flakes figure 1 As shown, ...

Embodiment 2

[0040] 1)Al 20 Si 20 mn 20 Fe 20 Ga 20 Preparation of High Entropy Alloy Flakes

[0041] First, the metal Al (99.99%), Si (99.99%), Mn (99.99%), Fe (99.99%), Ga (99.99%), according to the atomic ratio of 20:20:20:20:20 ingredients, select vacuum Melting in an induction melting furnace with a rated temperature of 1700°C to obtain Al 20 Si 20 mn 20 Fe 20 Ga 20 High-entropy alloy ingot 2Kg.

[0042] 2) Take a small amount of smelted Al 20 Si 20 mn 20 Fe 20 Ga 20 High-entropy alloy ingots, smashed into small pieces with a diameter of about 1cm.

[0043] 3) Take 70 g of the massive high-entropy alloy with a diameter of about 1 cm prepared in step 2), and use a vacuum strip-spinning machine to prepare a rapidly solidified strip-spin sheet at a roll speed of 10 m / s. High-entropy decaquasicrystals were obtained.

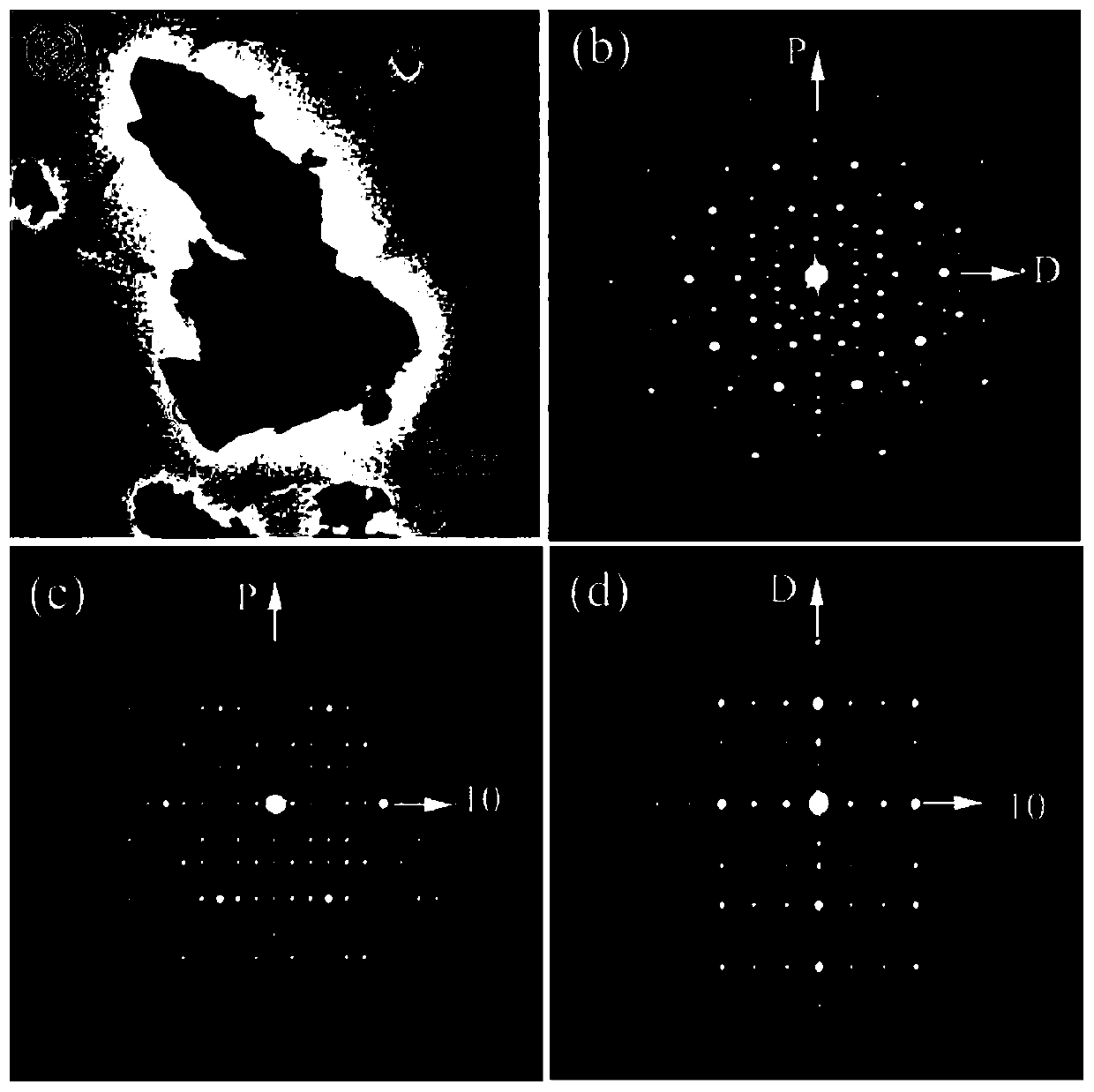

[0044] 4) if Figure 6 Shown in (b) is the selected-area electron diffraction pattern of ten times quasicrystals found in the flake strip alloy prepared in...

Embodiment 3

[0046] 1)Al 20 Si 20 mn 20 Fe 20 Ga 20 Preparation of High Entropy Alloy Flakes

[0047] First, the metal Al (99.99%), Si (99.99%), Mn (99.99%), Fe (99.99%), Ga (99.99%), according to the atomic ratio of 20:20:20:20:20 ingredients, select vacuum Melting in an induction melting furnace with a rated temperature of 1700°C to obtain Al 20 Si 20 mn 20 Fe 20 Ga 20 High-entropy alloy ingot 2Kg.

[0048] 2) Take a small amount of smelted Al 20 Si 20 mn 20 Fe 20 Ga 20 High-entropy alloy ingots, smashed into small pieces with a diameter of about 1cm.

[0049] 3) Take 70 g of the massive high-entropy alloy with a diameter of about 1 cm prepared in step 2), and use a vacuum strip-spinning machine to prepare a rapidly solidified strip-spin sheet at a roll speed of 35 m / s. High-entropy decaquasicrystals were obtained.

[0050] 4) if Figure 6 Shown in (c) is the selected area electron diffraction pattern of ten times quasicrystals found in the flake strip alloy prepared in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com