Aromatic polymer fiber with excellent interfacial properties and preparation method thereof

An aromatic polymer, interface performance technology, applied in fiber processing, fiber types, textiles and papermaking, etc., can solve problems such as fiber interface damage, improve compatibility, improve composite interface performance, and improve fiber surface roughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] 1. Preparation of aromatic polymer fibers containing fluorine on the surface:

[0051] (1.1) the preparation of aramid fiber (aramid fiber II, aramid fiber III) used in the present invention:

[0052] Poly(paraphenylene terephthalamide) fiber (aramid fiber II) is obtained by polymerizing and spinning two monomer raw materials of terephthaloyl chloride (TPC) and p-phenylenediamine (PDA). The molar ratio of phthaloyl chloride to p-phenylenediamine is 1:1.

[0053] Aromatic heterocyclic polyamide fiber (aramid III) is composed of three kinds of terephthaloyl chloride, p-phenylenediamine and 5(6)-amino-2-(4-aminophenyl) benzimidazole (PABZ). The monomer is prepared by polymerizing raw materials and spinning, and the ratio of terephthaloyl chloride: p-phenylenediamine: 5(6)-amino-2-(4-aminophenyl)benzimidazole is 100:50 :50.

[0054] (1.2) With reference to the methods disclosed in the invention patents CN 101798748 A and CN 104911895A already authorized by the applicant,...

Embodiment 1

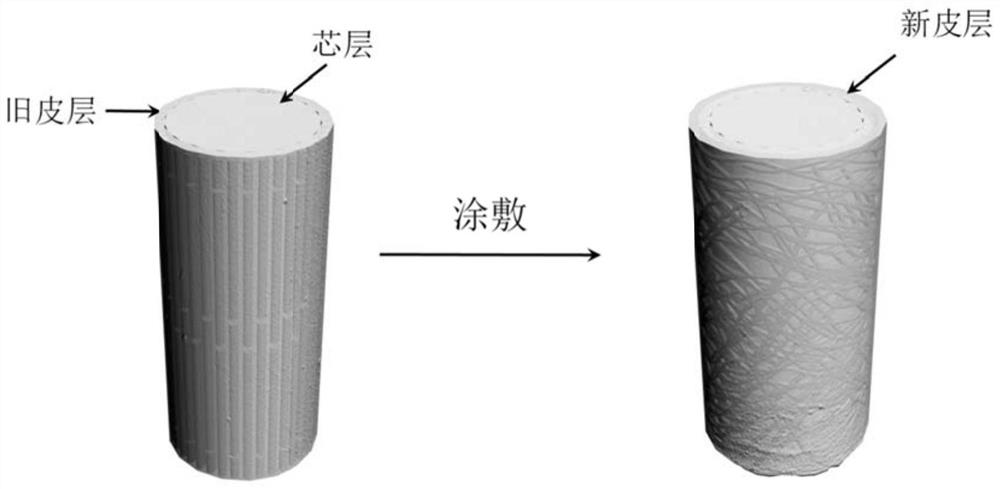

[0066] Use the above method (1.2) to fluorinate the aramid fiber III under the condition that the fluorine partial pressure is 1.5KPa and the nitrogen partial pressure is 15KPa to obtain the aramid fiber III with fluorine on the surface, and then dynamically pass through 25 ℃ contains a mixed solution of carbon nanotube derivatives and aromatic polyamide (the aromatic polyamide is obtained by polymerization of monomer molar ratio PABZ:TPC=10:10), the solution of carbon nanotube derivatives in the mixed solution The mass fraction is 0.01%, the mass fraction of the aromatic polyamide polymer solution is 0.5%, soaking for 0.5 minutes, coagulating and drying, and then heat-treating at 360°C to obtain the aromatic polymer fiber of the present invention. The preparation process of the aromatic polymer fiber is as follows figure 1 shown.

[0067] The obtained aromatic polymer fiber was added to E-51 epoxy resin matrix to prepare a corresponding composite material, and the mass fract...

Embodiment 2

[0069] Use the above-mentioned method (1.2) to fluorinate the aramid fiber III under the condition that the partial pressure of fluorine gas is 5KPa and the partial pressure of nitrogen gas is 60KPa, so as to obtain the aramid fiber III with fluorine on the surface, and then dynamically pass through 0 ℃ contains a mixed solution of carbon nanotube derivatives / aromatic polyamide (the aromatic polyamide is obtained by polymerization of the monomer molar ratio PDA:PABZ:TPC=5:5:10), and the carbon nanotubes in the mixed solution The mass fraction of the derivative solution is 0.0025%, the mass fraction of the aromatic polyamide polymer solution is 0.2%, soaking for 2 minutes, coagulating and drying, and then heat-treating to obtain the aromatic polymer fiber of the present invention.

[0070] The obtained aromatic polymer fiber was added to E-51 epoxy resin matrix to prepare a corresponding composite material, and the mass fraction of the aromatic polymer fiber in the composite mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com