A spin-mixed magnetorheological fluid high-speed shock absorber and a swirling mixing method for the magnetorheological fluid

A magneto-rheological fluid and rheological fluid technology, applied in the field of mechanical vibration reduction, can solve the problems of reducing the service life of the buffer, uneven force, prone to precipitation, etc., and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below with reference to the drawings:

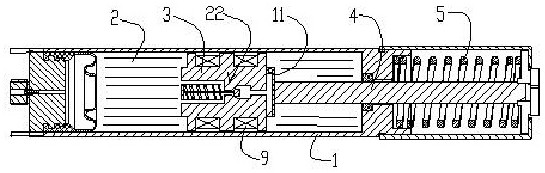

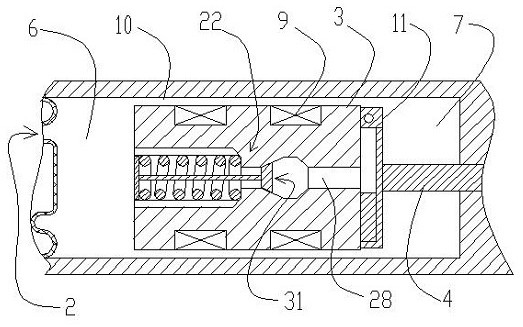

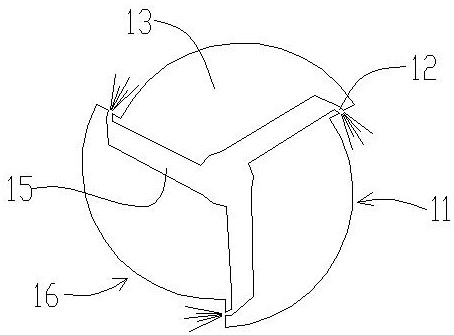

[0028] Such as figure 1 , 2 , 7, a spin magnetic flow soot high-speed damper, including the damper body 1, damping cylinder 2, piston 3, push rod 4 and reset spring 5; disposing damping cylinder on the damper body The piston 3 is located in the damper cylinder 2, separating the damper cylinder 2 as the front compression chamber 6 and the rear pressure chamber 7; the piston is provided with a mosaic slot 8 inlaid, in the inlay groove 8, in the inlay groove 8 The coil 9; the piston 3 and the electromagnetic coil 9 in the piston are in the inner wall of the damper cylinder 2, and one end of the push rod 4 is connected to the piston 3 in the damper cylinder 2, and the other end projects out of the damper cylinder 2. The reset spring 5 is provided on the push rod 4 outside the damper cylinder 2, and the piston 3 is located at one end of the backbound chamber 7, which is provided with a swirl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com