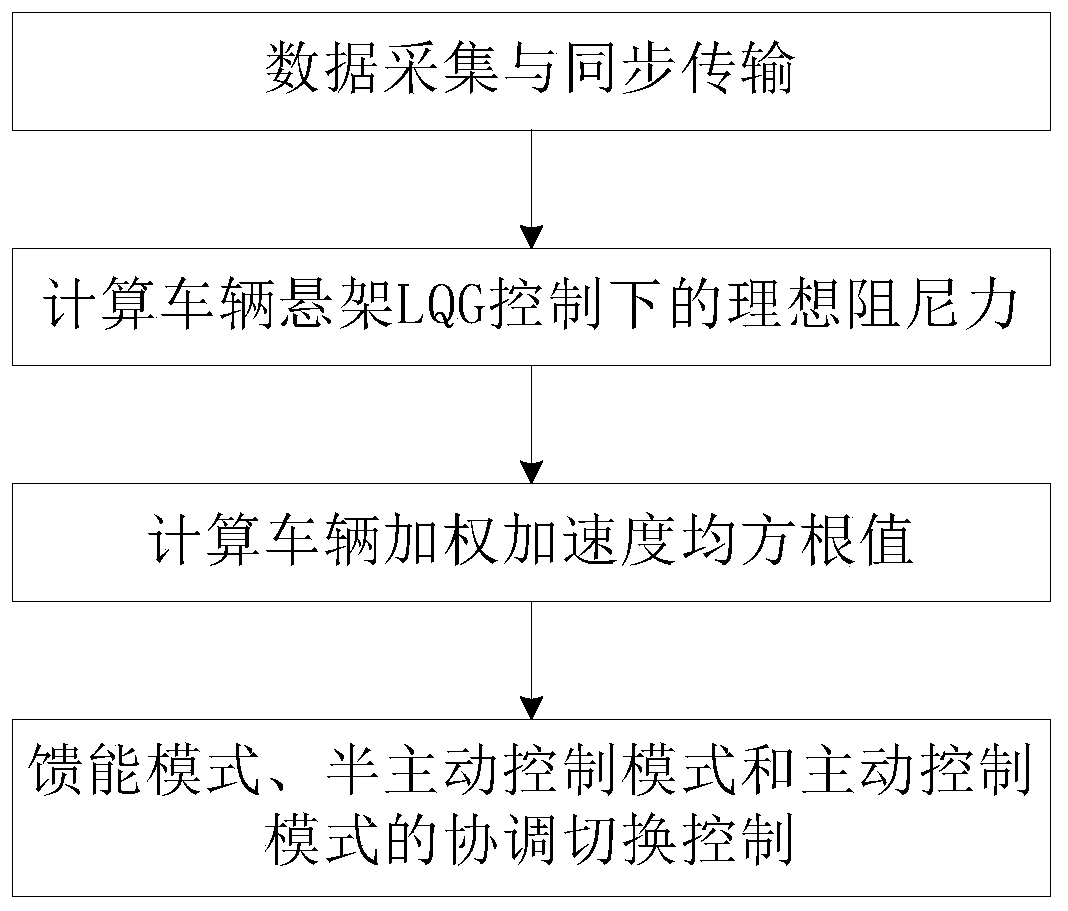

A Multi-mode Coordinated Switching Control Method for Vehicle Hybrid Suspension Actuators

A control method and actuator technology, which are applied to suspensions, elastic suspensions, vehicle components, etc., can solve the problems of restricting the promotion of automotive active suspensions, large size, and inability to adapt to vehicle driving conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

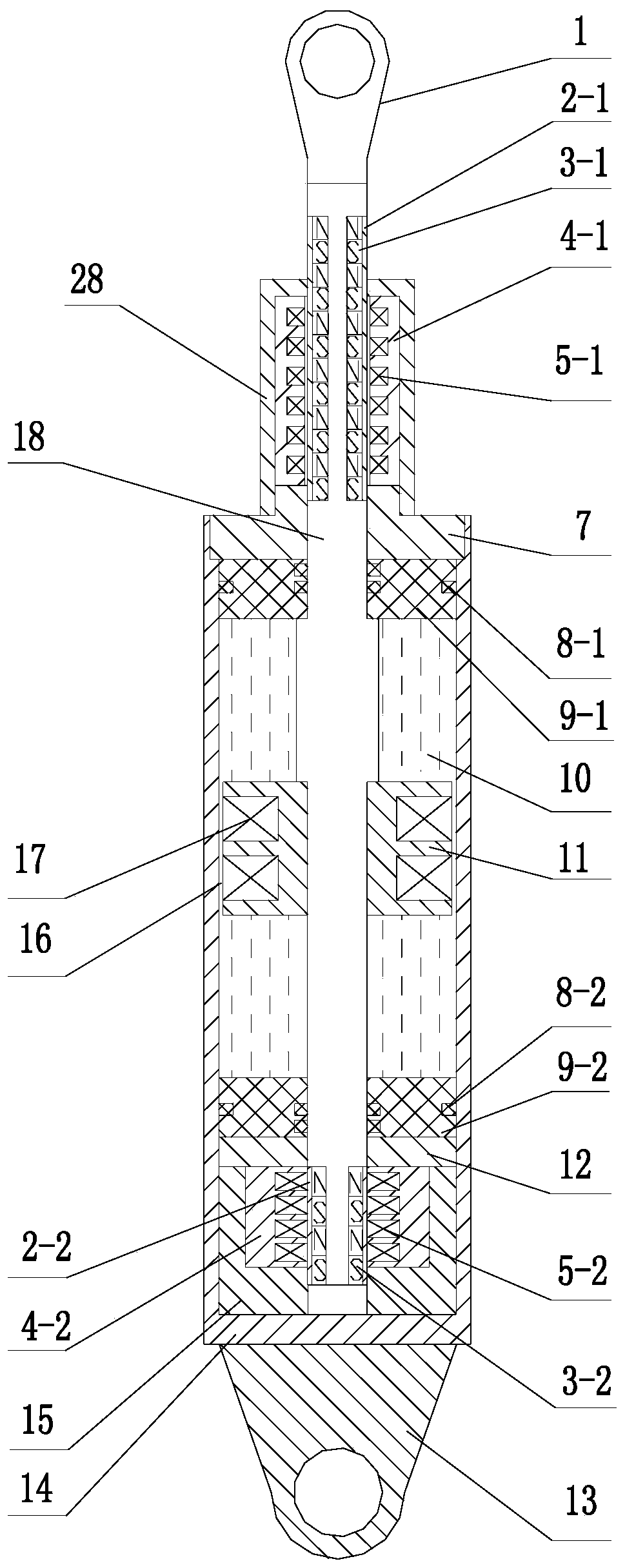

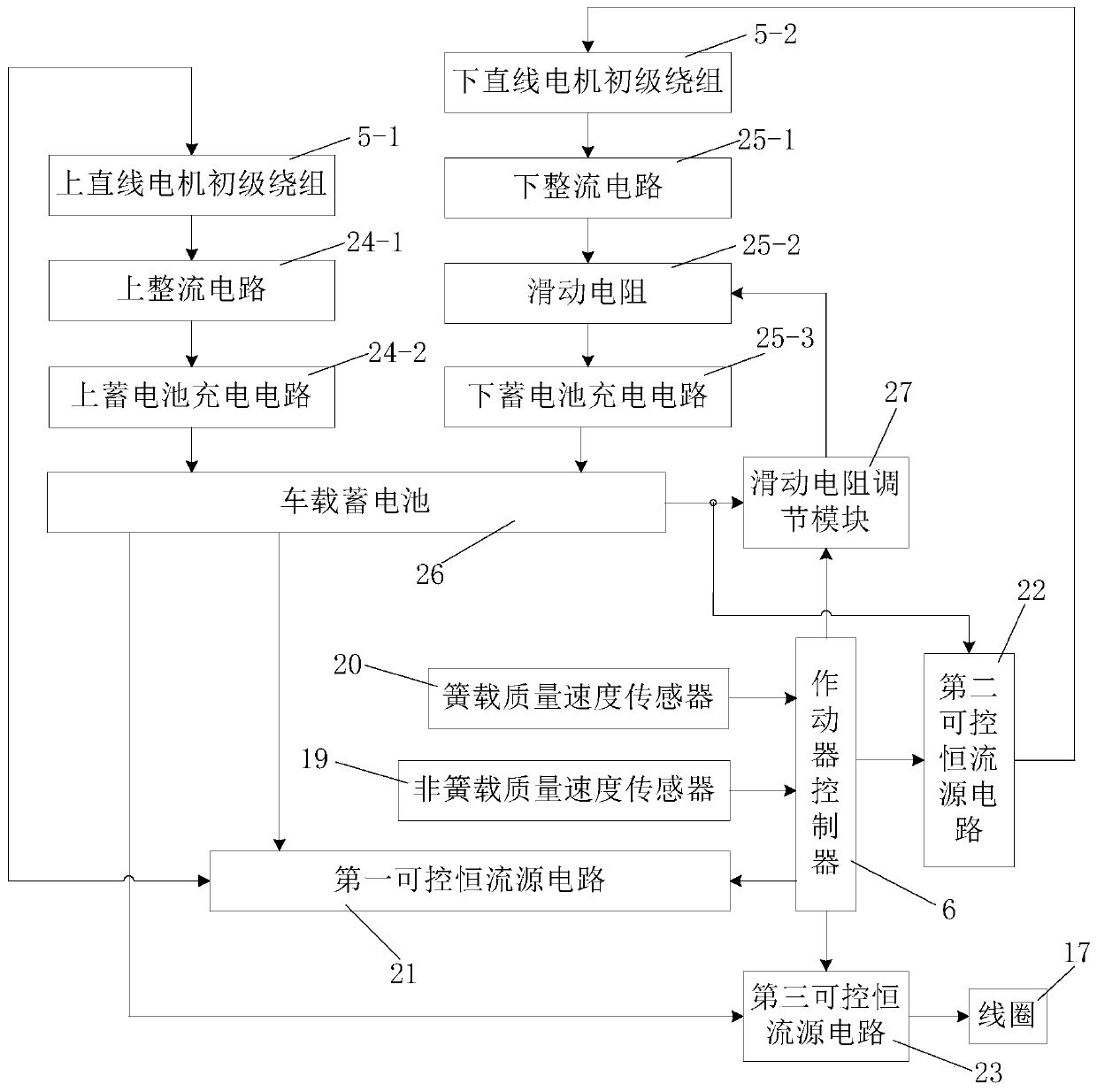

[0062] Such as figure 1 As shown, the vehicle hybrid suspension actuator of the present invention includes an actuator body and a control unit, and the actuator body includes a double-outlet rod type magneto-rheological shock The upper linear motor unit on the upper part of the shock absorber and the lower linear motor unit arranged on the lower part of the double-rod magneto-rheological shock absorber;

[0063] The double-rod magnetorheological shock absorber includes a working cylinder 14 and a piston rod 18 that is arranged in the working cylinder 14 and extends upwards outside the top of the working cylinder 14, and the piston rod 18 extends out of the top of the working cylinder 14. One section is the motor shaft of the upper linear motor unit, and the bottom section of the piston rod 18 is the motor shaft of the lower linear motor unit. The upper part of the working cylinder 14 and the bottom of the upper linear motor unit are provided with a shaft for the piston rod 18....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com