Sensing device for dynamically measuring siltation and volume change in reservoir

A dynamic measurement, reservoir technology, applied in the direction of measurement devices, measurement capacity, volume measurement instruments/methods, etc., can solve the problems of shocking personnel and property losses, and achieve the effect of meeting special requirements, solving complexity, and being convenient to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

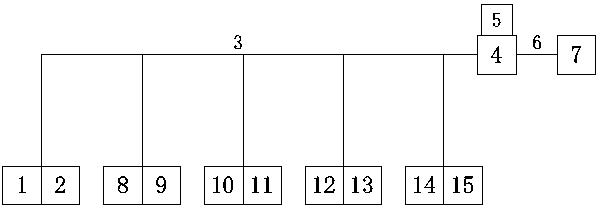

[0034]The device consists of an anti-clogging and anti-harsh environment input liquid level sensor 1, a positioning sensor 2, a monitoring communication wire 3, a measurement and control host 4, a special measurement and control software 5, an output device 6, a host computer 7, and an anti-blocking and anti-harsh environment input liquid level sensor. Sensor 8, positioning sensor 9, anti-clogging and anti-harsh environment input liquid level sensor 10, positioning sensor 11, anti-clogging and anti-harsh environment input liquid level sensor 12, positioning sensor 13, anti-clogging and anti-harsh environment input liquid level sensor 14 Composed of positioning sensor 15; anti-clogging and anti-harsh environment input liquid level sensor 1 is installed in the fluid level to be monitored, and the monitoring communication wire 3 connected to it is 100 meters long. In addition, a heavy hammer is arranged at the bottom of the sensor to complete complex working conditions Under the f...

Embodiment approach 2

[0044] The anti-clogging and anti-harsh environment input liquid level sensor 1 is installed in the fluid level to be monitored, and the monitoring communication wire 3 connected to it is 50 meters long. The number of sensors of the same type that can be connected is 300 sensors. Its good anti-clogging characteristics make this The sensor can accurately monitor the liquid level of the fluid in the fluid state in which 60% of the solid matter is present, and the others are the same as in Embodiment 1.

Embodiment approach 3

[0046] Anti-clogging and anti-harsh environment input liquid level sensor 1 is installed in the fluid level to be monitored, and the monitoring communication wire 3 connected to it is 5-100 meters long. The number of sensors of the same type that can be connected is 2 sensors, and its good anti-clogging characteristics This enables the sensor to accurately monitor the fluid level in fluids with 5% solids, and the others are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com