Pump pressure tightness test assembly, broadside pipeline and installation method of broadside pipeline

An installation method and a technology of sealing components are applied in the direction of detecting the appearance of fluid at the leakage point and using liquid/vacuum degree to measure the liquid tightness, etc., which can solve the problems of long cycle, harsh construction environment, and consuming manpower and material resources, etc., to achieve The construction environment is good, the construction difficulty is reduced, and the construction efficiency is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

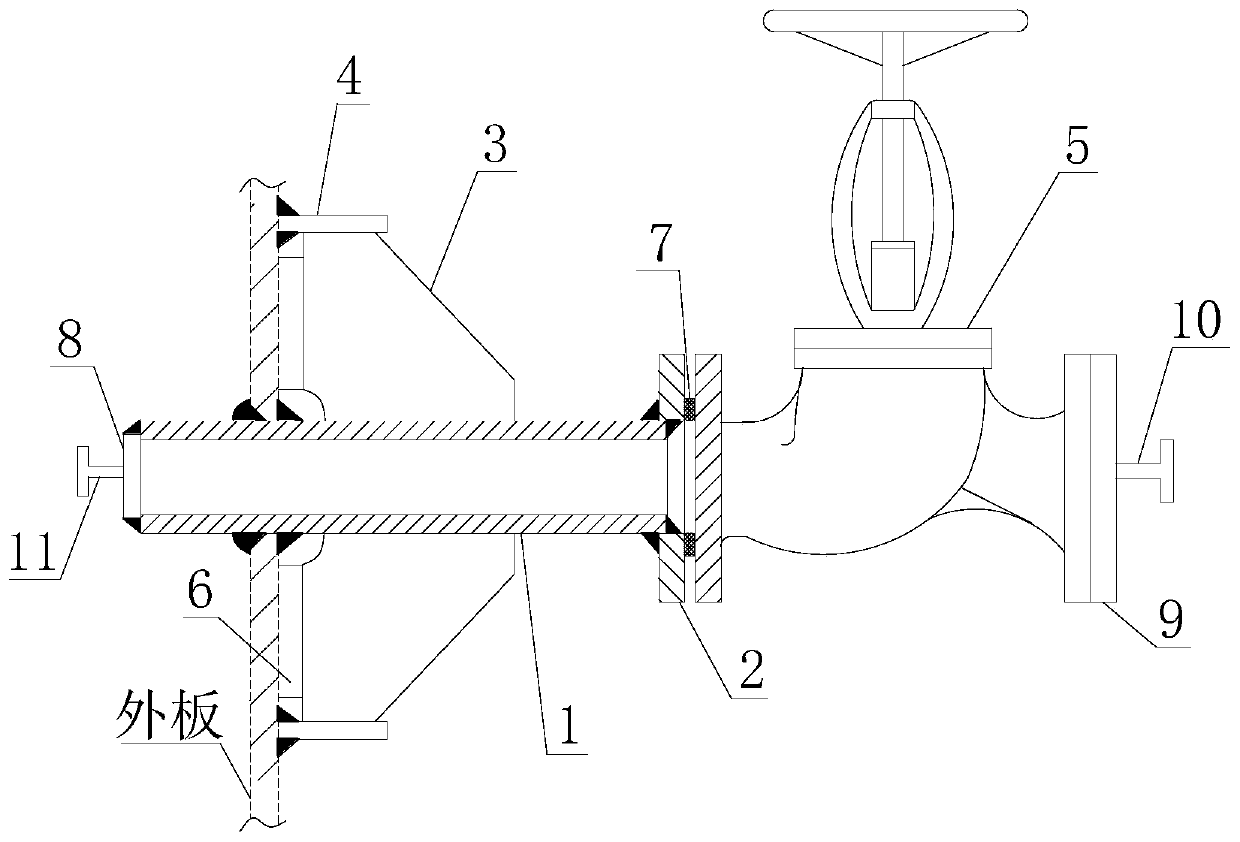

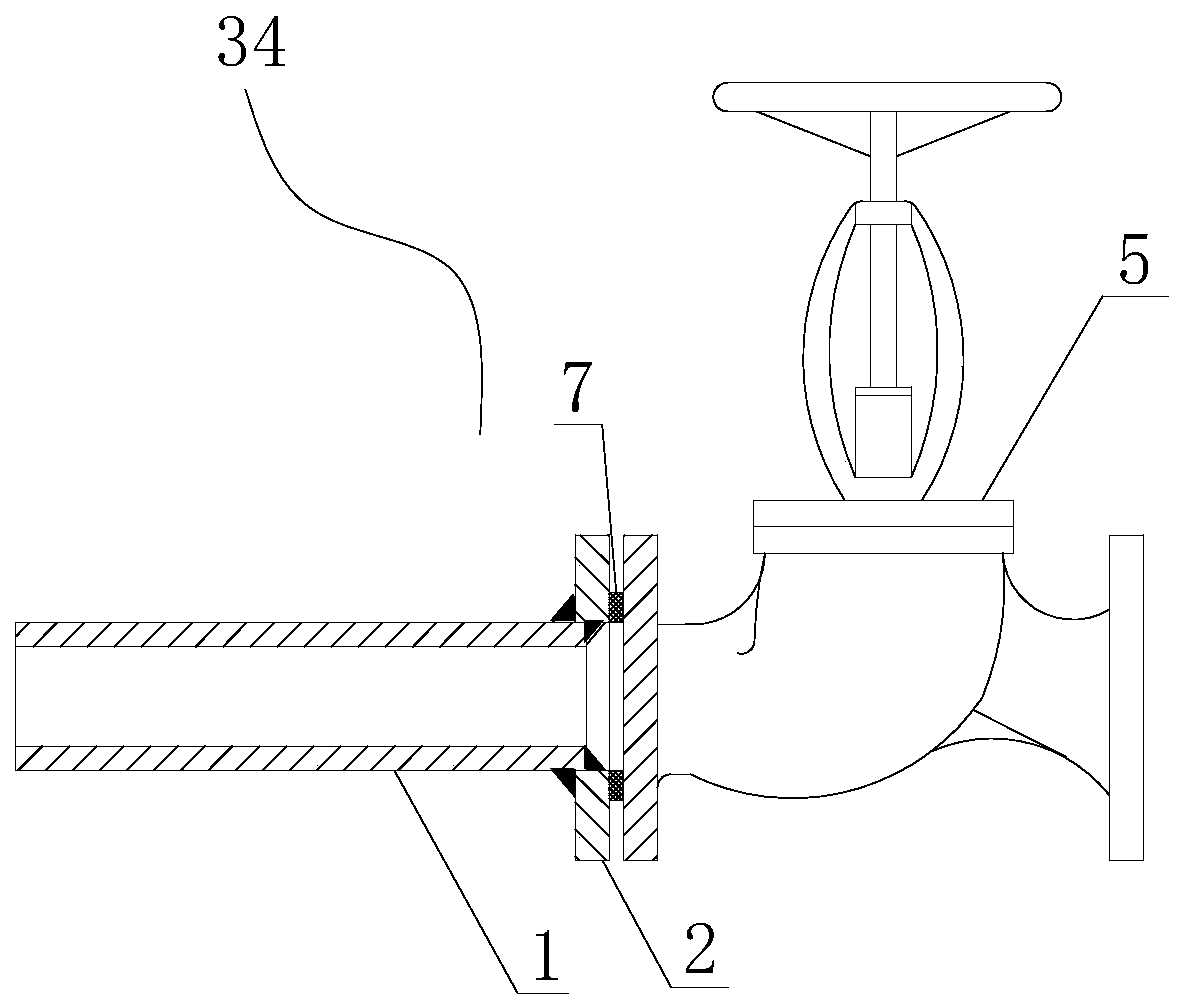

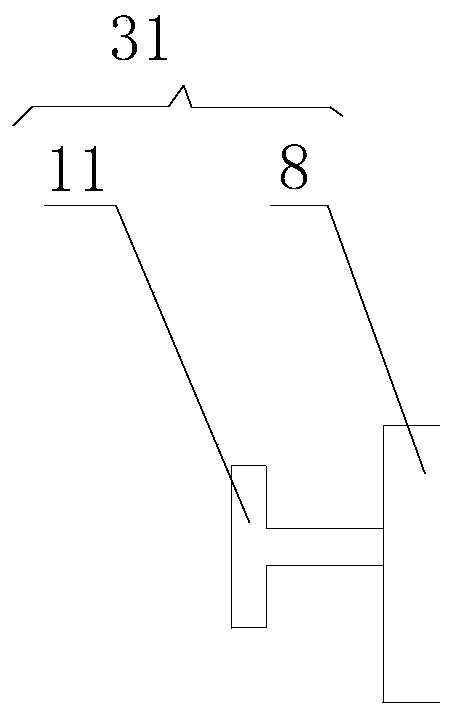

[0042] Such as figure 2 , image 3 and Figure 4 As shown, a pump pressure test assembly is used to assist in the pump pressure test of the pipe valve assembly 34 of the ship. The pipe valve assembly 34 includes the side pipe 1 and the side valve 5 . The pump pressure sealing test assembly includes a sealing test sealing plate 8 and a sealing test flange 9. The sealing test sealing plate 8 is sealingly connected to the side end surface of the side pipe 1, and a first connecting hole is opened in the center of the sealing test sealing plate 8, and a second connecting hole is set at the first connecting hole. A threaded connection pipe 11. The first threaded connecting pipe 11 directly communicates with the side pipe 1 through the first connecting hole. Preferably, the sealing plate 8 is welded to the side end surface of the side pipe 1 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com