Self-propelled synchronous pruning machine for hedge top surface and side surface branches and leaves

A self-propelled, trimmer technology, applied in the field of hedge trimming, can solve problems such as single function, poor reliability, and inability to achieve flatness, and achieve the effects of widespread application value, reduced use cost, and safe and reliable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

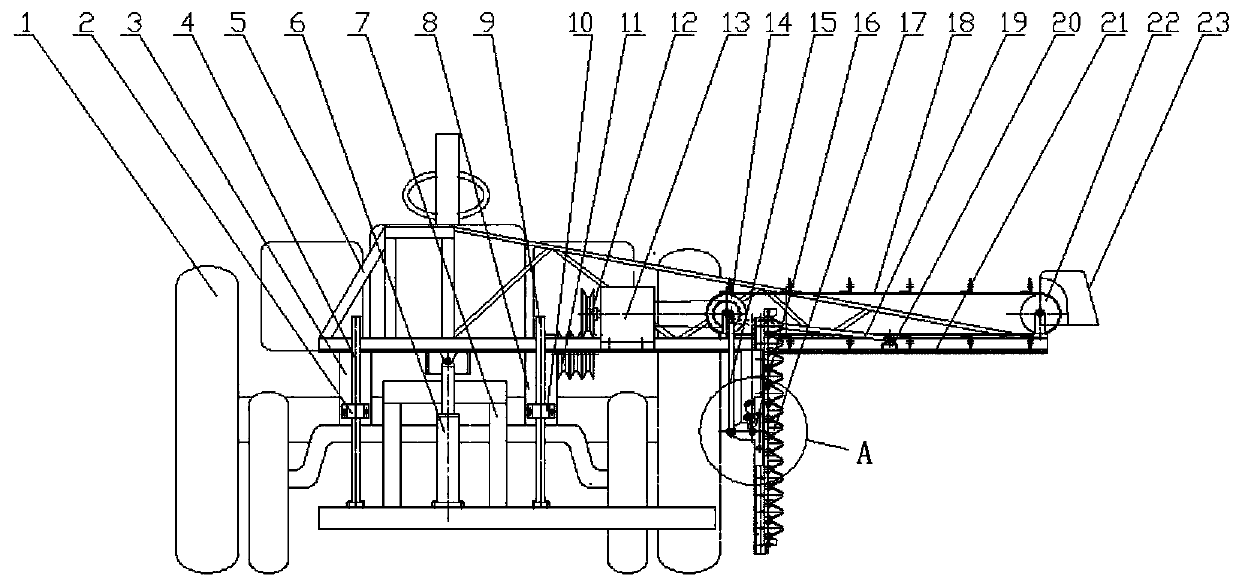

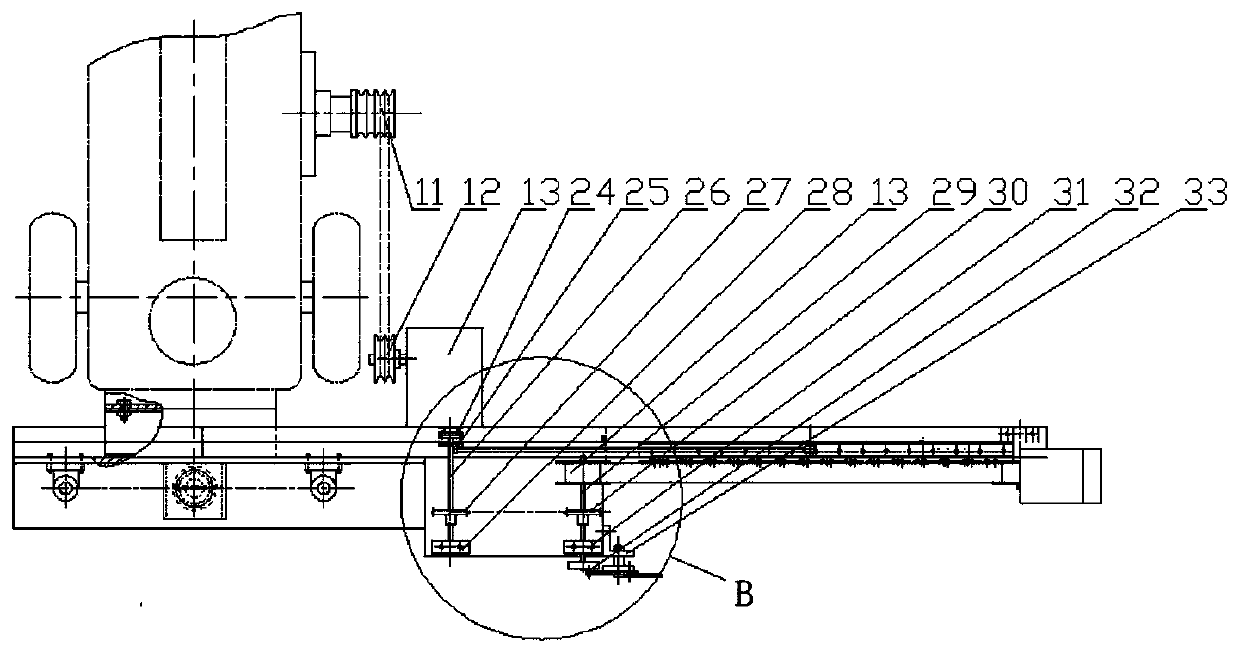

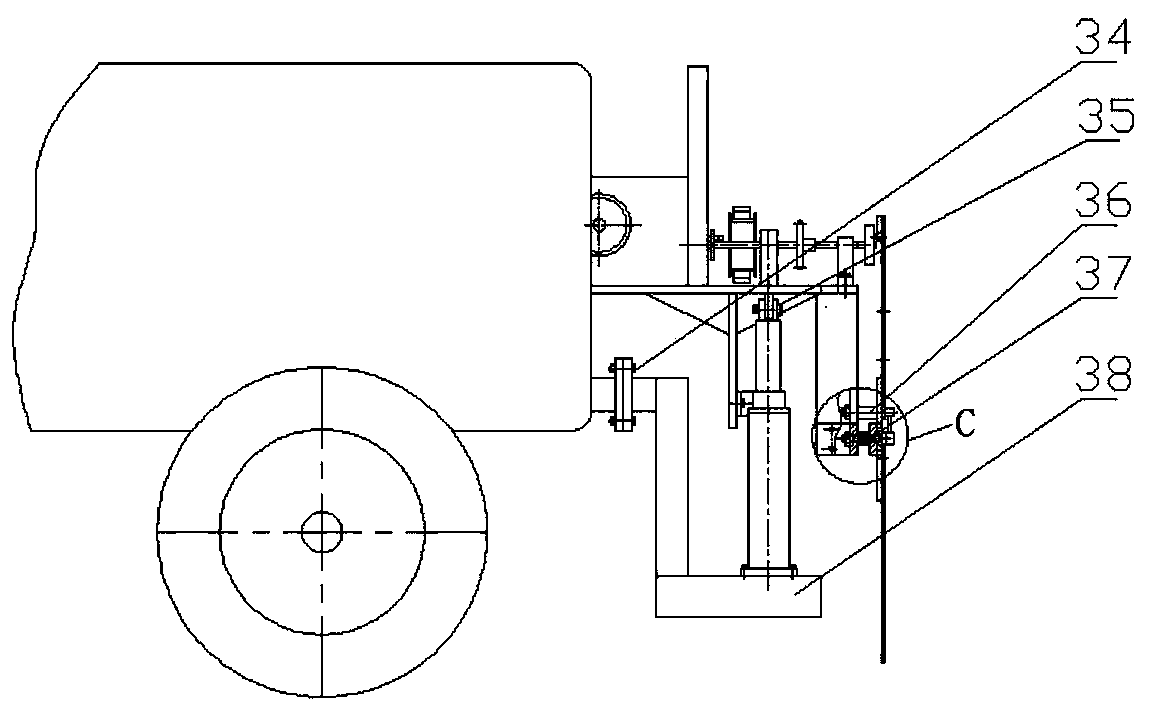

[0032] See Figure 1~4 In the embodiment of the present invention, a self-propelled hedge trimmer for the top and side branches and leaves of a self-propelled hedgerow includes a tractor 1 and a base 38. The front of the tractor 1 is provided with a base bracket 7, and the base 38 is installed at the bottom of the base bracket 7. The upper side of the base 38 is provided with a truss 5, the truss 5 is provided with shaft one 26 and shaft two 29, the ends of shaft one 26 and shaft two 29 are respectively provided with bearing seat 28 and bearing seat two 31, tractor 1 and shaft There is a transmission mechanism between No. 26 and No. 29;

[0033] The truss 5 is provided with a side cutter moving blade fixing seat 16 and a top surface cutter moving blade fixing seat 20. The side cutter moving blade fixing seat 16 is equipped with a side cutter 17 and a top surface cutter moving blade fixing seat. A top surface cutter 21 is installed on 20. The self-propelled hedge trimmer for top ...

Embodiment 2

[0045] See Figure 1~4 In the embodiment of the present invention, a self-propelled hedge trimmer for the top and side branches and leaves. The difference is that the left and right sides of the bottom of the truss 5 are equipped with a cleaning pulley 14 and a cleaning pulley 22. The cleaning pulley A cleaning conveyor belt 18 is installed on the one 14 and the cleaning pulley two 22. A plurality of L-shaped cleaning scrapers with even intervals are fixed on the cleaning conveyor belt 18 by screws. A discharge port 23 is provided on one side of the cleaning conveyor belt 18; During the cutting process of the face cutter 21, the cut hedge branches and leaves are scraped and transported to the outlet 23 on the side of the hedge through the cleaning conveyor belt 18, which avoids problems such as accumulation of branches and leaves during cutting and cleaning.

[0046] The self-propelled hedge trimmer can complete the trimming of the two sides and the top surface in one round trip....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com