Dust falling device for house building construction

A technology for dust suppression devices and houses, which is applied in the direction of spraying devices, use of liquid separation agents, and separation of dispersed particles, which can solve the problems of troublesome dust suppression work and inconvenient movement of dust suppression mechanisms, and achieve the effect of increasing the dust suppression range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

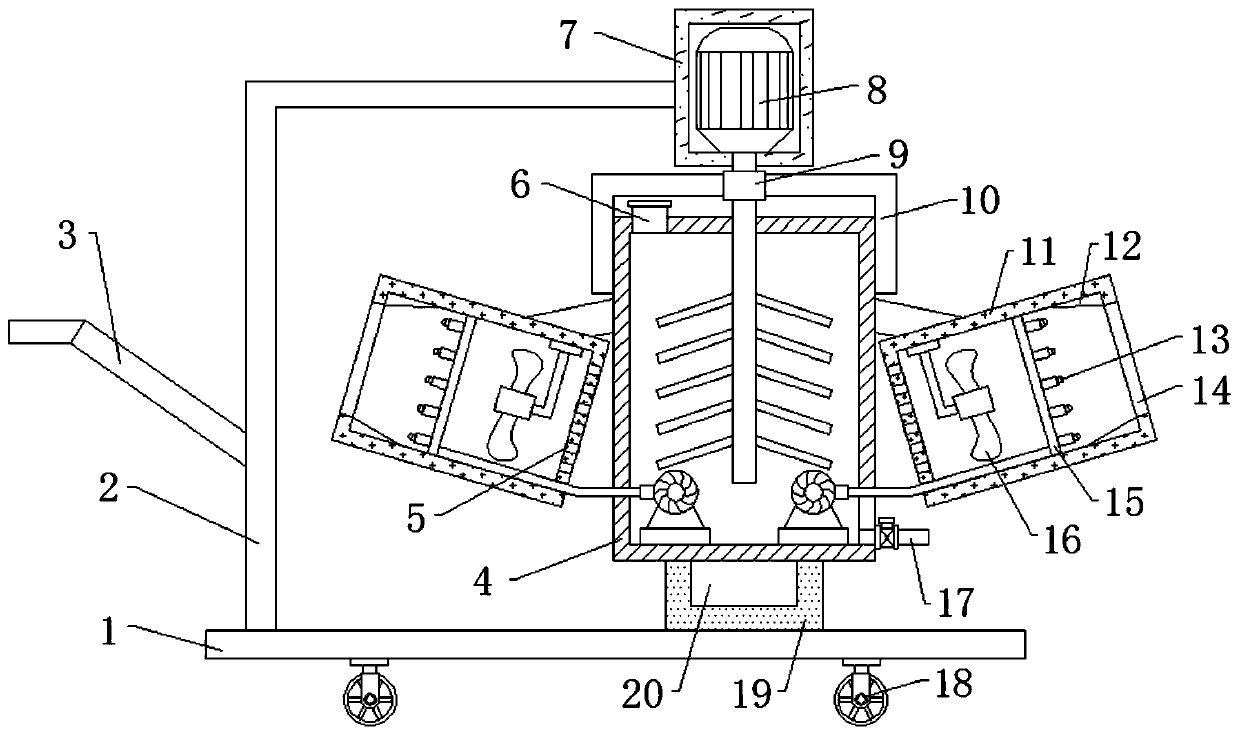

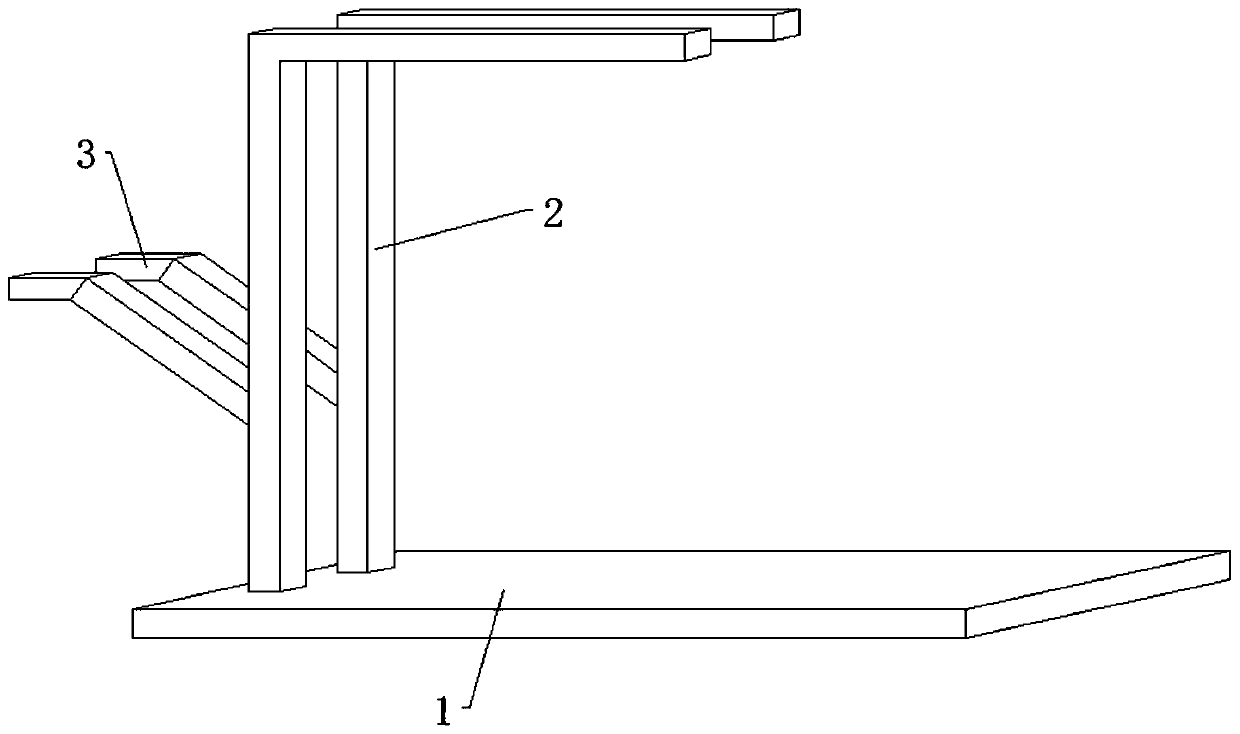

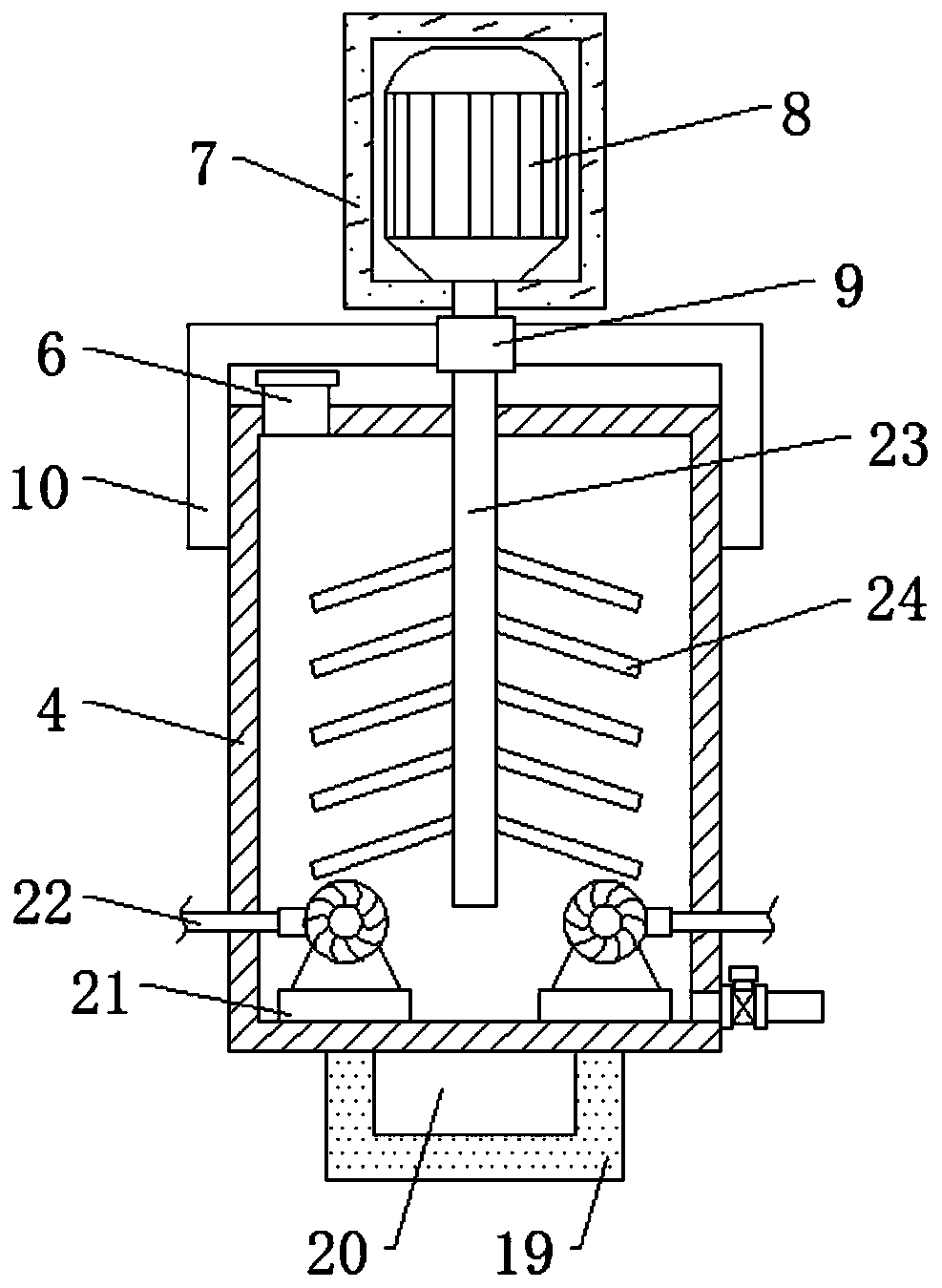

[0027] refer to Figure 1-3 , a dust suppression device for house construction, comprising a bottom plate 1 and a water tank 4, a fixing seat 19 is fixed on the top outer wall of the bottom plate 1 by bolts, a socket 20 is rotatably inserted on the top outer wall of the fixing seat 19, and the water tank 4 is fixed on the bottom wall by bolts On the top outer wall of the socket 20, two L-shaped plates 2 are fixed on one side of the top outer wall of the bottom plate 1 by bolts, one end of the L-shaped plates 2 is fixed with a handle 3 by bolts, and one end of the two L-shaped plates 2 is fixed by bolts There is the same motor box 7, and the motor box 7 is located directly above the water tank 4. The bottom inner wall of the motor box 7 is fixed with a motor 8, and one end of the output shaft of the motor 8 is keyed to a drive shaft 23, and one end of the drive shaft 23 is located at In the inside of the water tank 4, a sleeve rod 9 is sleeved on the circumference outer wall of...

Embodiment 2

[0032] refer to Figure 4 , a dust suppression device for house construction. Compared with Embodiment 1, this embodiment also includes a lighting lamp 25, and the lighting lamp 25 is fixed on one side of the outer wall of the motor box 7 by bolts.

[0033] During use, one side of the motor case 7 is provided with an illuminating lamp 25, which is convenient to provide illumination, and is convenient for the device to carry out dust reduction work when the sky is dark.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com