Automatic calcium carbonate feeding device used for organic silicon sealant production

An automatic feeding device and sealant technology, which is applied in the direction of feeding device, transportation and packaging, cleaning methods and utensils, etc., can solve the problems of physical health hazards of operators in the field environment, floating near the feeding hopper, low intelligence, etc. , to achieve the effect of saving manpower, avoiding the clogging of the filter holes and ensuring the filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0033] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings. It should be understood that these descriptions are only exemplary and not intended to limit the scope of the present invention. In addition, in the following description, descriptions of well-known structures and technologies are omitted to avoid unnecessarily obscuring the concept of the present invention.

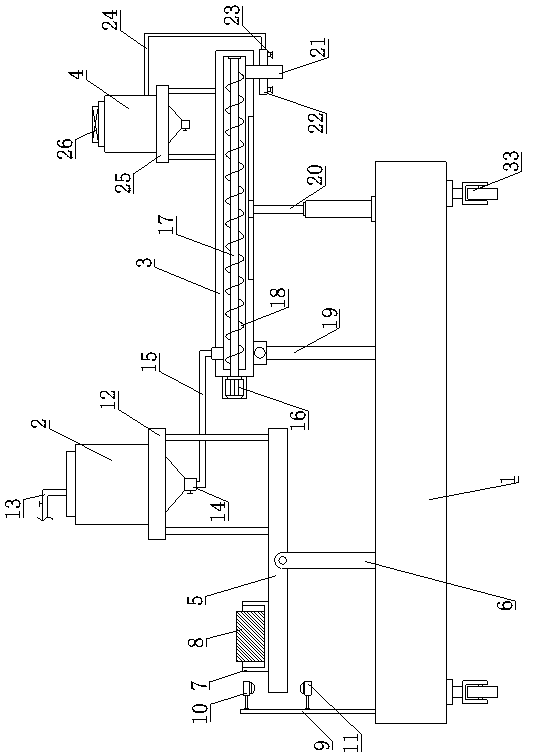

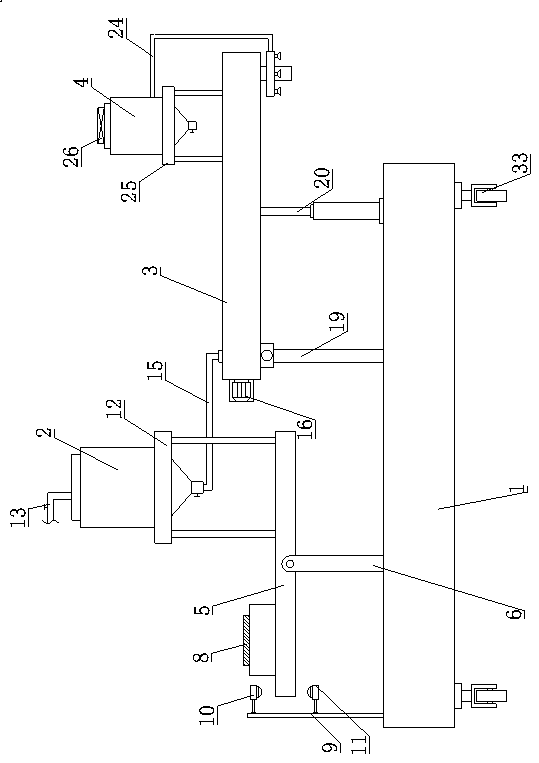

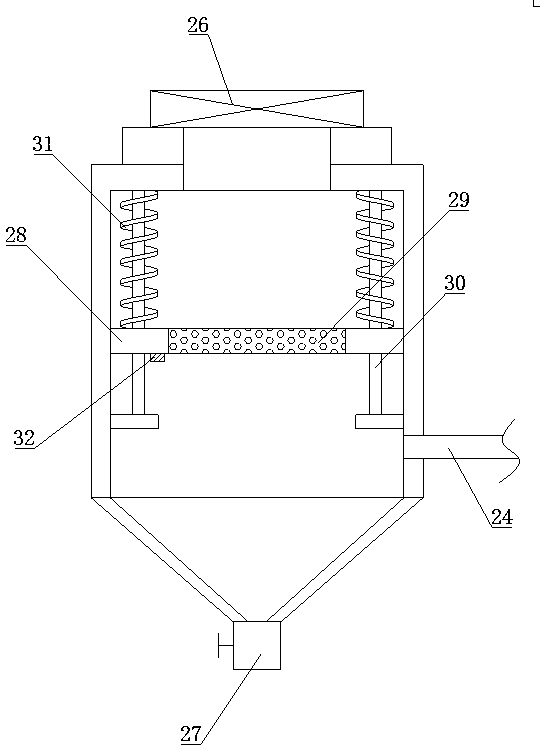

[0034] Such as Figure 1-4 As shown, an automatic calcium carbonate feeding device for the production of silicone sealant proposed by the present invention includes a fixed seat 1, a transition box 2, a conveying device 3, a recovery device 4, a balance plate 5, and a first support 6 , The fixed rod 9, the conveying hose 15, the driving device 16, the conveying shaft 17, the second support 19, the lifting device 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com