Auxiliary machining equipment for end rolling machine

A technology of auxiliary processing and rolling head mill, applied in metal processing equipment, workpiece surface treatment equipment, metal rolling, etc., can solve the problems of reduced efficiency, affecting the production time of enterprises, inconvenient to process small steel, etc. Efficiency, guaranteeing processing efficiency, guaranteeing the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

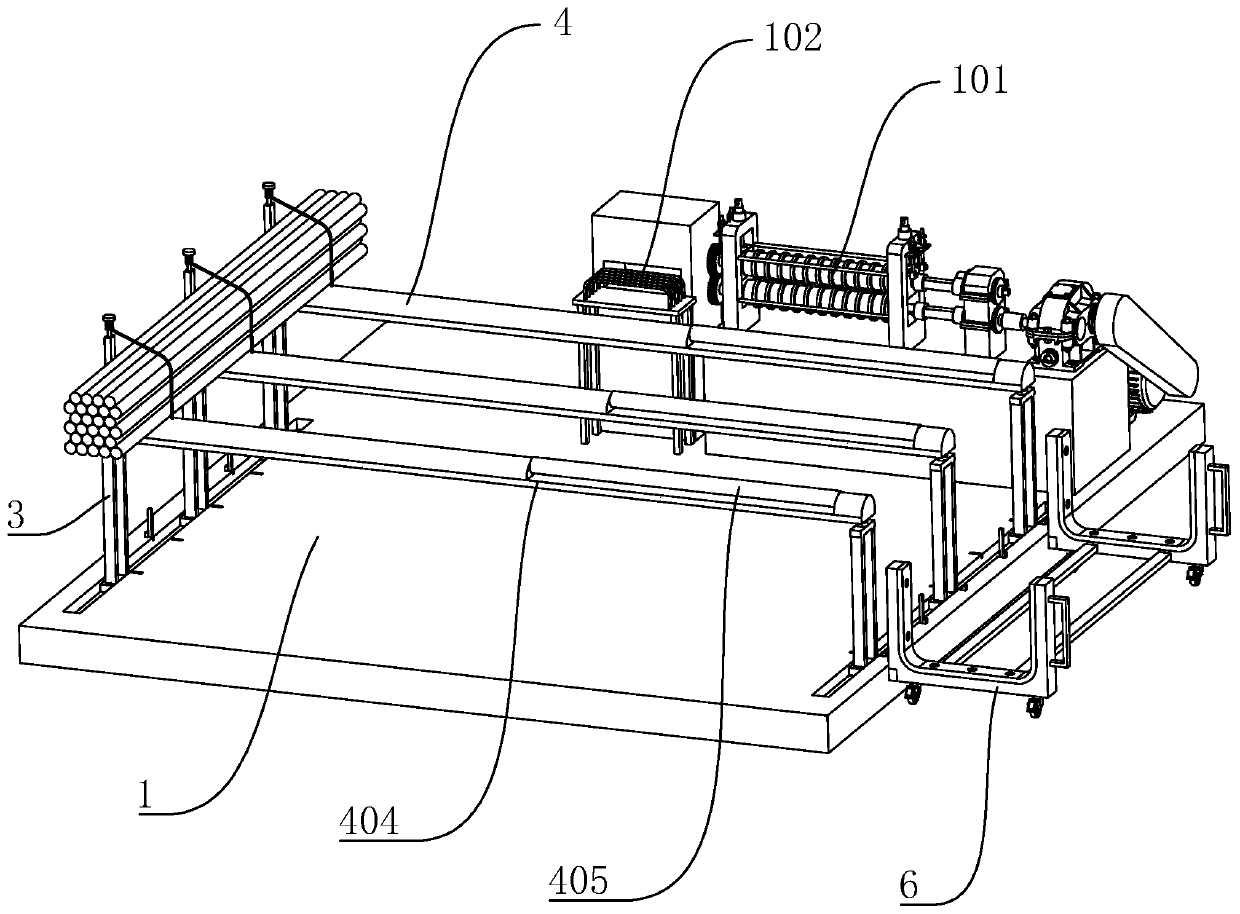

[0037] A kind of auxiliary processing equipment for rolling head machine, refer to figure 1 , including a base plate 1 , a frame 101 and a heating furnace 102 located on the upper surface of the base plate 1 . The base plate 1 is preferably a solid iron plate with a horizontal upper surface. The frame 101 is a high-power rolling head machine, which sits on the upper surface of the base plate 1 to process the steel rolling head. The heating furnace 102 is preferably a medium frequency induction furnace, which is located at one end of the frame 101 in the longitudinal direction to heat the end of the steel.

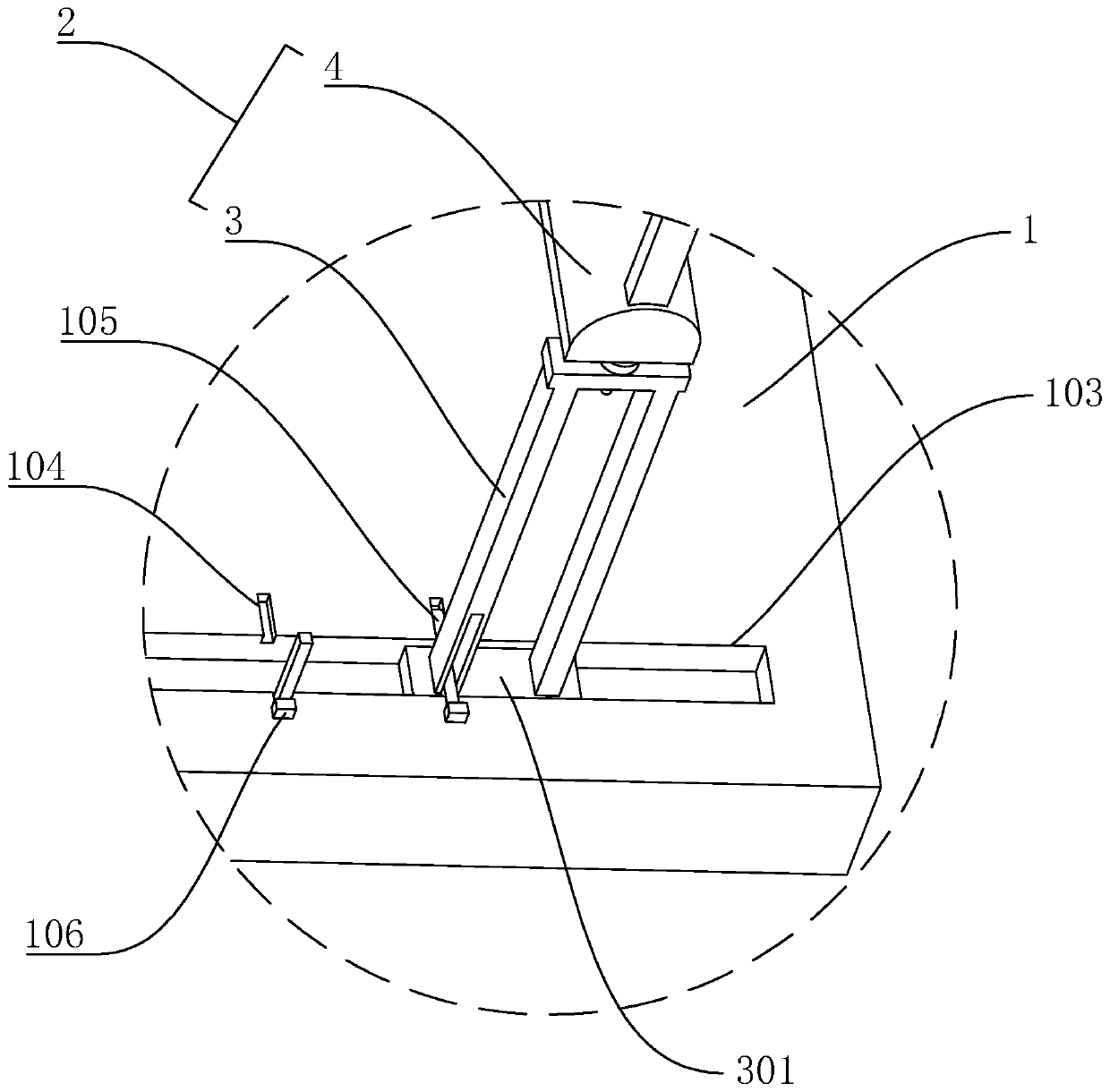

[0038] refer to figure 1 and image 3 On the upper surface of the base plate 1 and on one side in the width direction of the frame 101, several support frames 2 are provided. The support frame 2 is used to place the steel to be processed, and can assist the operator to send the steel into the frame 101 more labor-saving. In the rolling head, in this embodiment, the numbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com