Manufacturing technology for round wing type butterfly bolts through cold heading

A butterfly bolt and manufacturing process technology, applied in the direction of bolts, nuts, threaded fasteners, etc., can solve the problems of butterfly bolts such as small size, slow processing speed, poor mechanical properties, etc., to achieve reduced manufacturing process and high production efficiency , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Further description will be made below in conjunction with the accompanying drawings of the description.

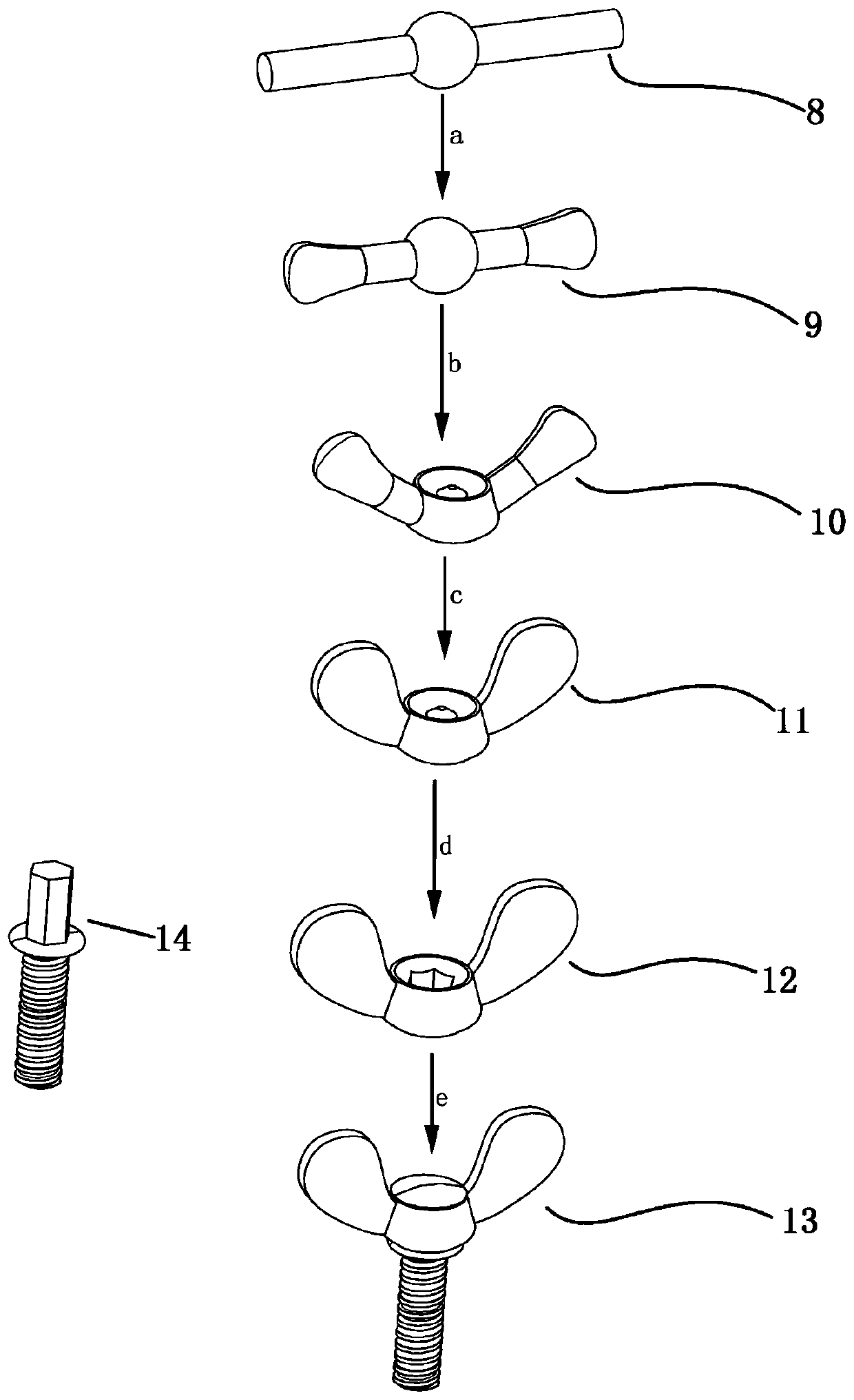

[0030] Cold heading blank step: Take a cylindrical raw material for cold heading, and cold heading it into an initial blank 8 with a spherical shape in the middle and cylindrical shapes on both sides. The axial length of the initial blank 8 is 34mm, and the height of the cylinders on both sides is 12mm and the diameter of the middle sphere is 10mm.

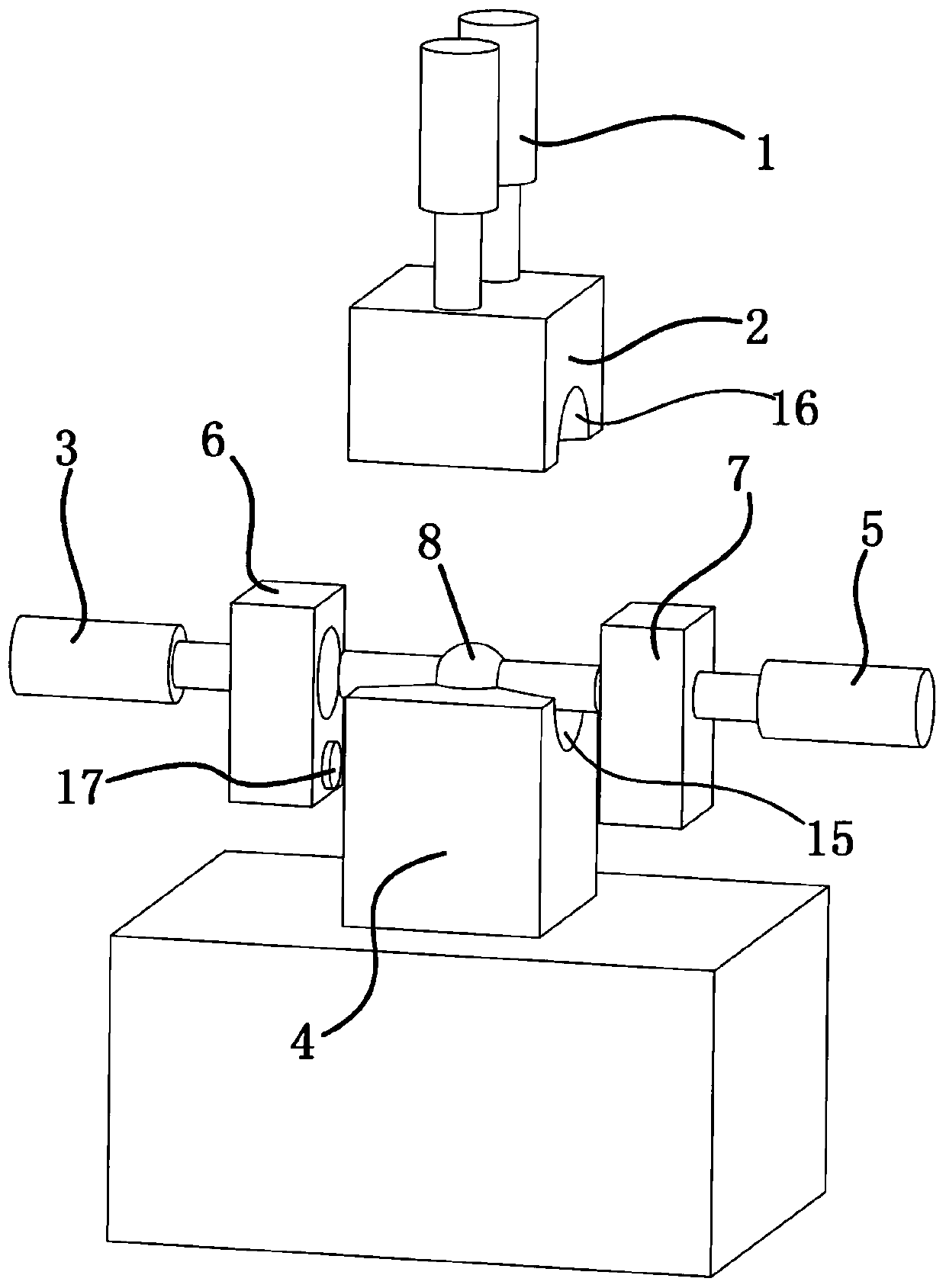

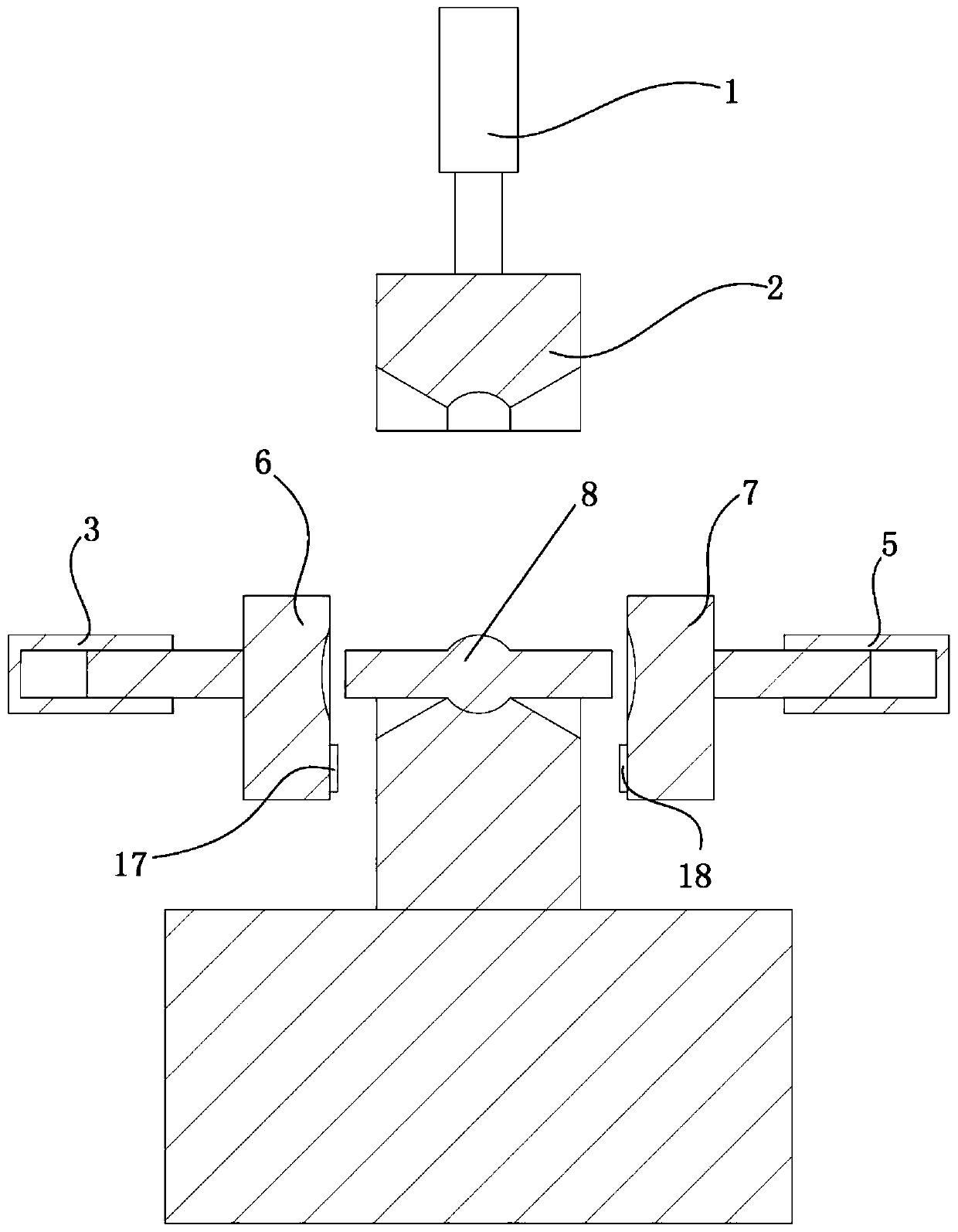

[0031] Stamping round head step: further process the initial blank 8, put the initial blank 8 into a round head extrusion device for extrusion, and obtain a round head blank 9 with a spherical shape in the middle and round-bottomed cones on both sides. The axial length of 9 is 30mm, and the height of the circular bottom cone on both sides is 10mm. The round head extrusion device used in stamping round head step a comprises extrusion lower die 4, the lower extrusion groove 15 in the extrusion lower die 4 is a combinati...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap