A quantitative oil supply device when producing gears in hobbing mode

A mode and gear technology, applied in the direction of gear tooth manufacturing devices, components with teeth, belts/chains/gears, etc., can solve the problem that the pipeline cannot stop the flow of oil in time, and achieve the effect of ensuring smooth cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

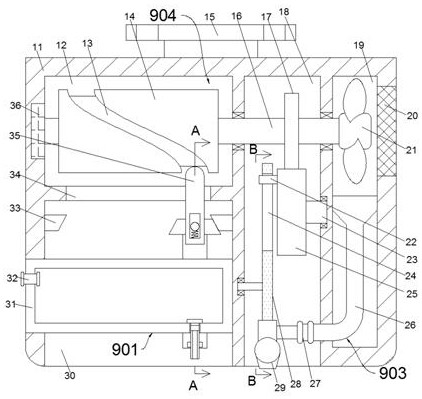

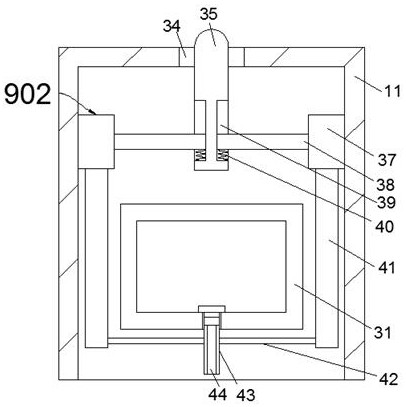

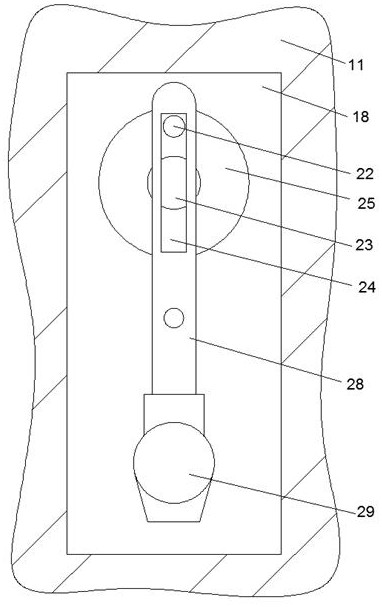

[0016] By below Figure 1 - Figure 3 The present invention will be described in detail, which is convenient, and now the above-mentioned orientation is as follows: below figure 1 The projection relationship of the projection is consistent with the front and back and so on.

[0017] The present invention relates to a quantitative model during production gear hobbing oil installations, mainly used in the production of quantification when hobbing gear mode to process oil, the present invention in conjunction with the following drawings further illustrate the present invention:

[0018] The present invention employs one of the dosing device during oil production mode gear hobbing, including filling tank 11, filling tank 11 equipped with the transmission chamber 12, the lower end of the inner wall of the gear chamber 12 equipped with an opening downward delivery chamber 30, a delivery chamber 30 equipped with a spraying device 901 serving lubricating fluid, said spray device 901 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com