Brush head bristle flattening device

A flat wool and brush head technology, applied in the field of flat wool machines, can solve the problems of poor product consistency and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

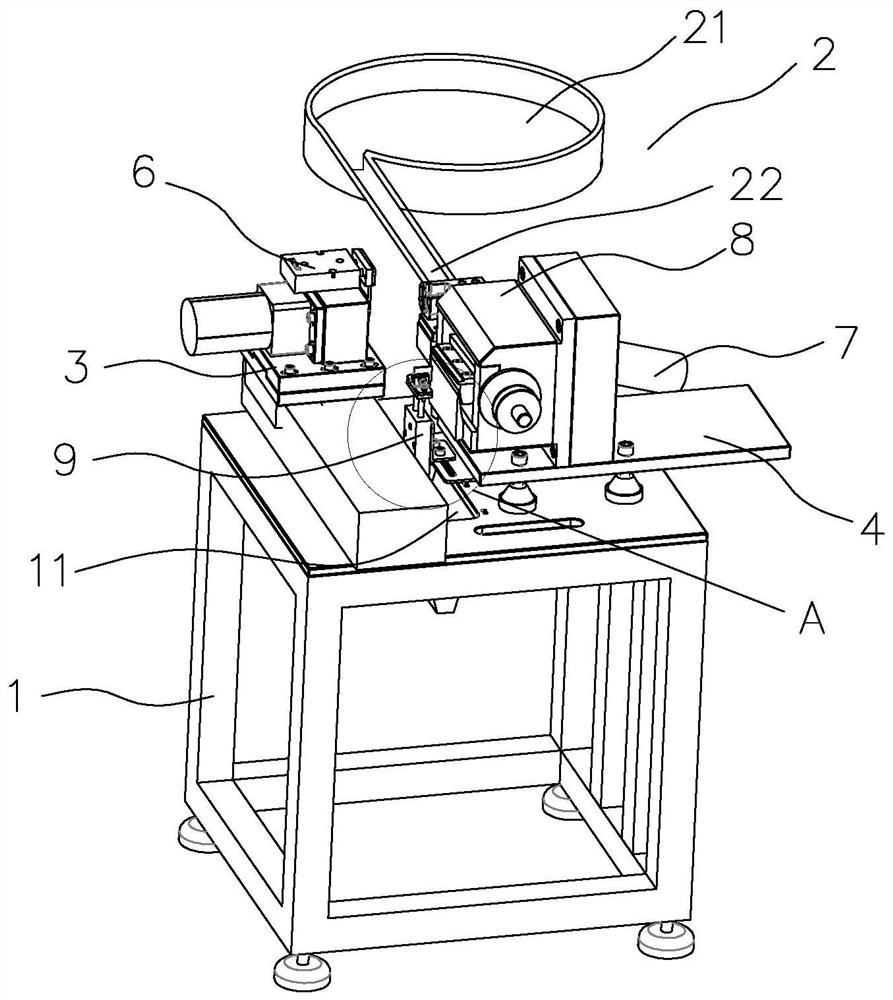

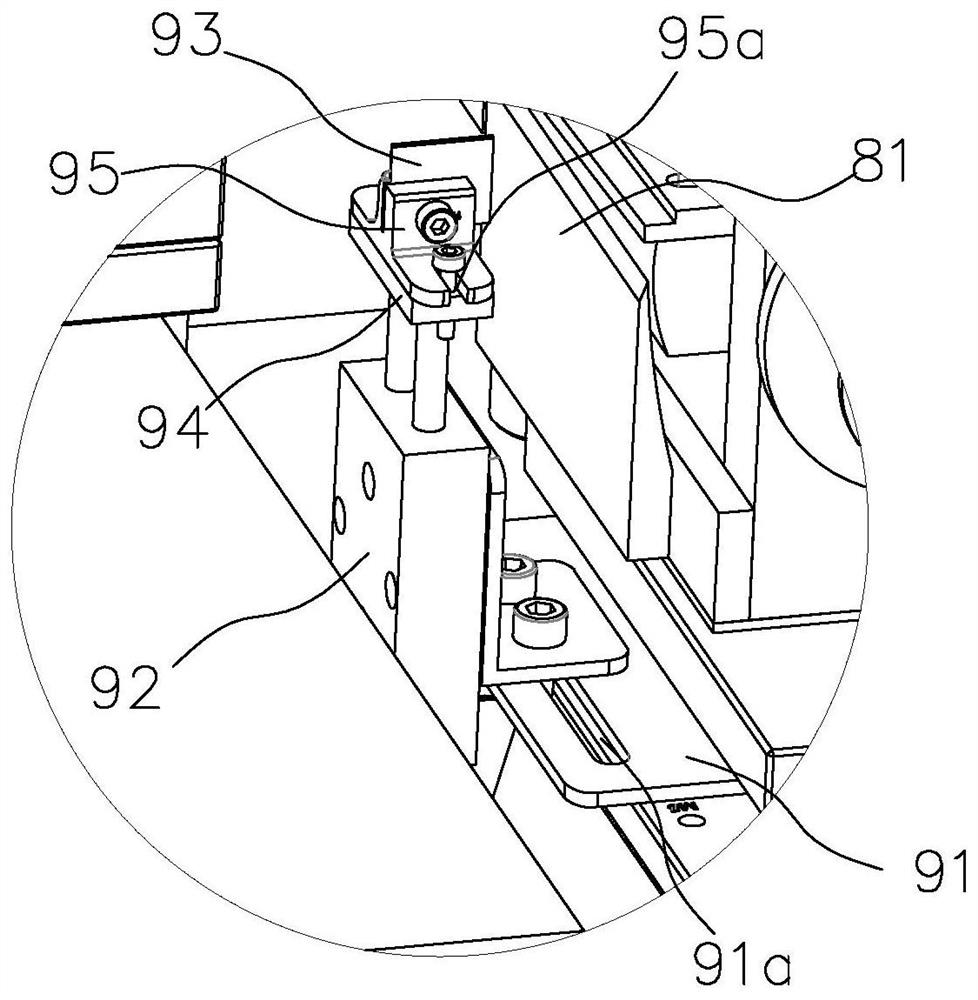

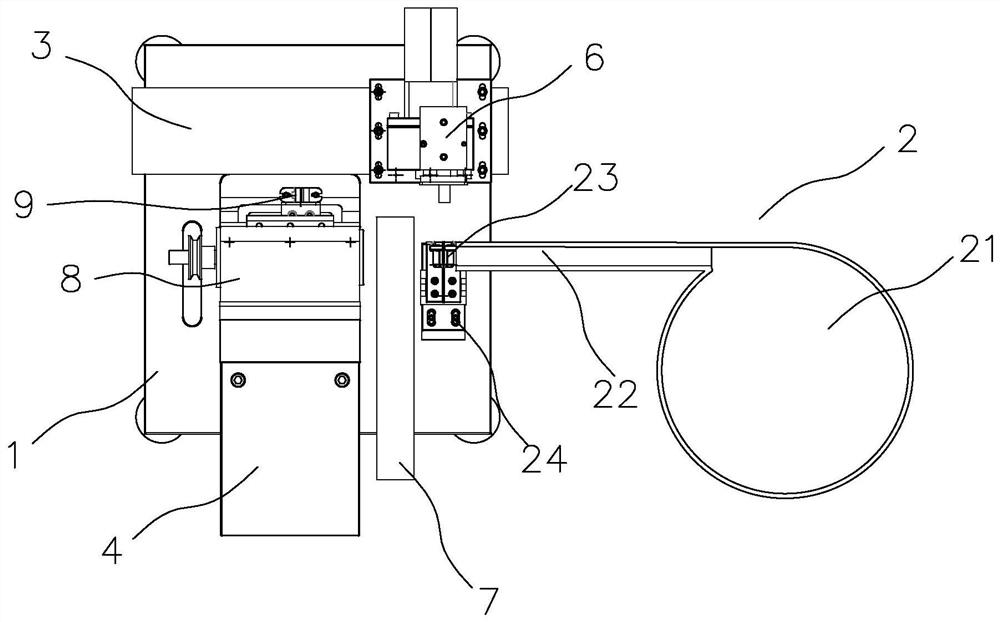

[0032] refer to Figure 1 to Figure 6 , the present embodiment provides a brush head flat bristle device, comprising a frame 1, an input device 2 arranged on the frame 1, a brush head pushing device 3 is provided on the side of the frame 1 opposite to the input device 2, the The frame 1 is provided with a support 4 on one side of the input device 2, the support 4 is provided with a brush head cutting device 5, and the brush head pushing device 3 includes a first device that can push the brush head to the brush head cutting device 5. A linear motion mechanism 31, a rotary mechanism 32 mounted on the first linear motion mechanism 31, and a fixed shaft 33 that can fix the brush head on the rotary mechanism 32, the brush head cutting device 5 includes a rotatable frame mounted on the bracket 4, the rotating shaft 51 on the rotating shaft 51, the tool ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com