Method for removing pump shaft of marine motor

A technology for marine motors and pump shafts, which is applied in the field of ships, can solve the problems of dismantling marine motors and pump shafts, and achieve high-quality dismantling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

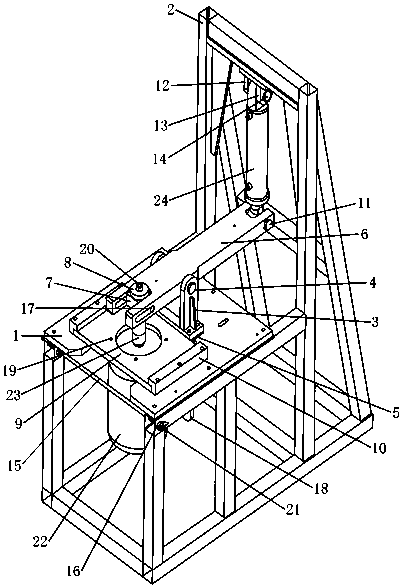

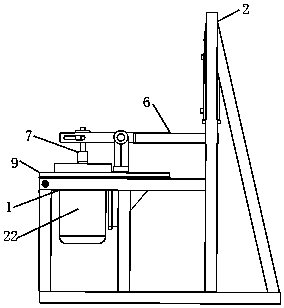

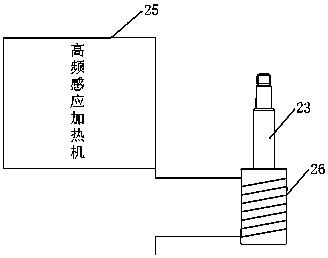

[0026] Take the dismantling of a marine vertical seawater pump as an example. There is no transitional installation between the seawater pump and the motor. The seawater pump casing and the motor casing are directly connected by fasteners. The seawater pump shaft is made in the form of a half set and a half shaft. The positive fit is connected with the motor shaft through the key transmission mode, and the part of the half shaft extends into the centrifugal pump casing, and is connected with the impeller through the key transmission mode with a small gap fit. After the motor pump is used for a long time, the part of the half set and the motor shaft are corroded and integrated. When the part of the half shaft is worn out, it cannot meet the requirements of the seawater pump, and the motor pump shaft must be removed. For the disassembly of the seawater pump shaft, the disassembly steps and process are explained in detail.

[0027] How to remove the pump shaft sleeve:

[0028] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com