Pushing and pressing vegetable cutter

A vegetable cutting machine and push plate technology, which is applied in metal processing, food processing, applications, etc., can solve the problems of large device volume, high cost, inconvenient use of food cutting devices, etc., and achieve the effect of small size and low device cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

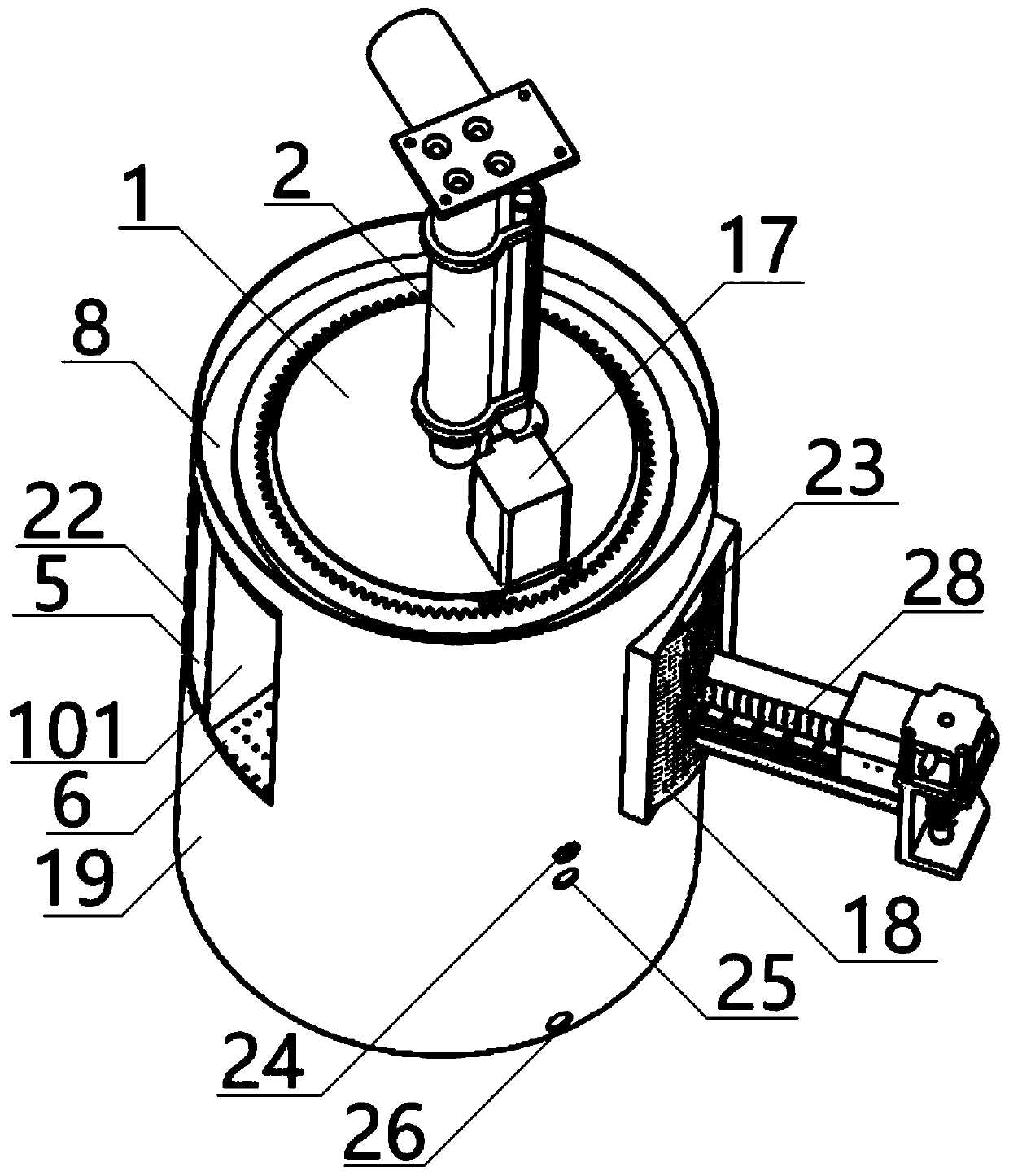

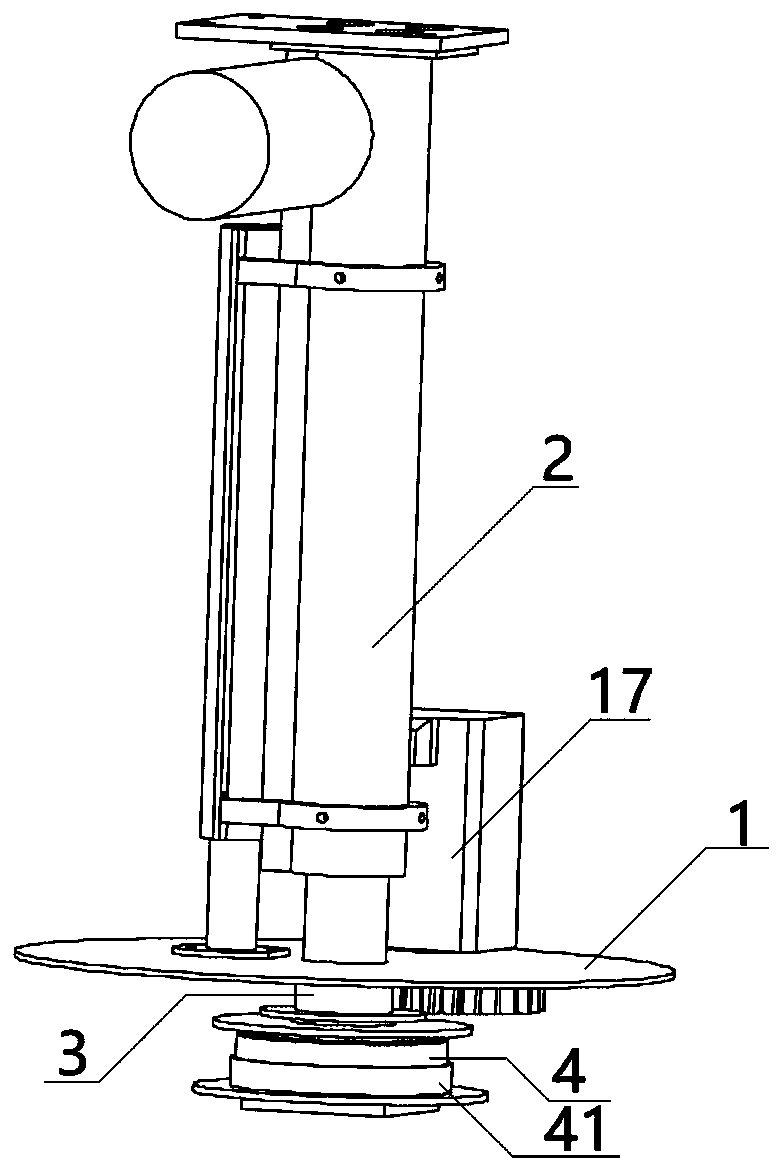

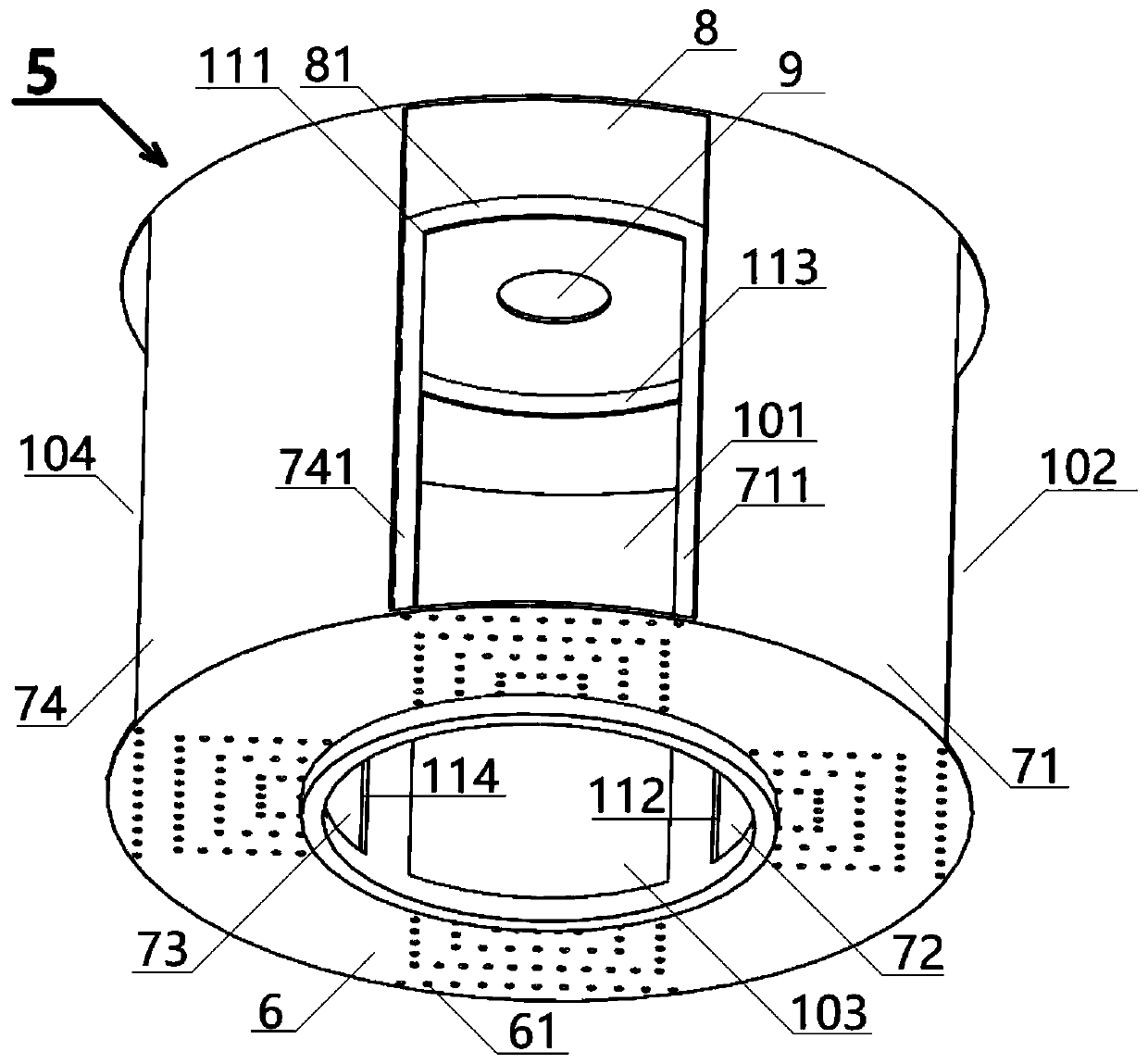

[0014] Such as figure 1 As shown, a kind of pushing and pressing vegetable cutter according to the present invention includes a mounting plate 1, and an electric push rod 2 is installed on the mounting plate 1, such as figure 2 As shown, the center of the bottom of the mounting plate 1 is provided with a hollow mounting sleeve 3, the bottom end of the push rod of the electric push rod 2 is inserted into the mounting sleeve 3 so that the electric push rod 2 is fixedly connected with the mounting plate 1, and the electric push rod 2 can drive Mounting plate 1 moves down and up. The bottom end of the installation sleeve 3 is provided with a bearing 4 and a bearing seat 41, and the bearing 4 and the bearing housing 41 connect the installation sleeve 3 with the vegetable serving tray 5, so that the vegetable serving tray 5 can follow the drive of the electric push rod 2. Mounting plate 1 moves down and moves up, also can rotate around vertical axis, and the rotation of this veget...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com