Liquid-cooling high-current charging system of electric automobile and control method thereof

A charging system, a technology for electric vehicles, applied in electric vehicle charging technology, electric vehicles, charging stations, etc., can solve the problems of increased volume and weight of charging connection devices, unsafe charging process, and inability to increase charging power, etc. The effect of resource usage, increasing charging current, and increasing charging power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

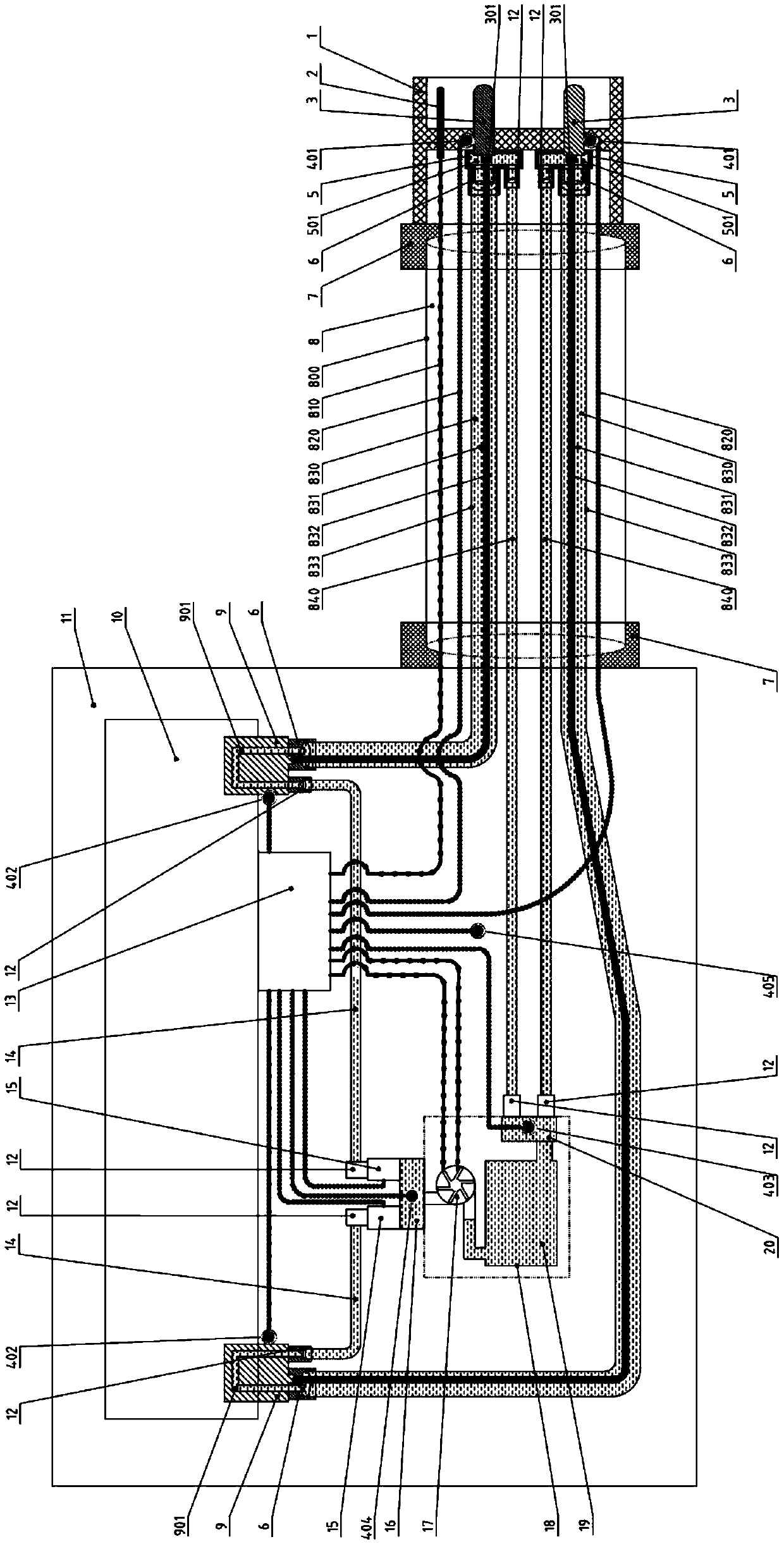

[0044] Such as figure 1 As shown, a liquid-cooled high-current charging system for electric vehicles includes a charging connector 1, a cable fixing and protection device 7, a cable body 8, a charging pile 11, and a charging pile power module 10; both ends of the cable body 8 pass through The cable fixing and protection device 7 is respectively connected with the charging electrical connector 1 and the charging pile 11, and the charging pile power module 10 is installed in the charging pile 11.

[0045] Terminals 9 are installed at both ends of the charging pile power module 10, and a liquid return storage device 16, a liquid circulation pump 17, a radiator 18, and a liquid outflow storage device 20 connected in sequence are installed in the charging pile 11. A cooling fluid circulation channel 901 is reserved in the terminal 9, a power contact 3 is installed in the charging connector 1, and a liquid-cooled cable connection device 5 with a cooling fluid circulation cavity 501 is i...

Embodiment 2

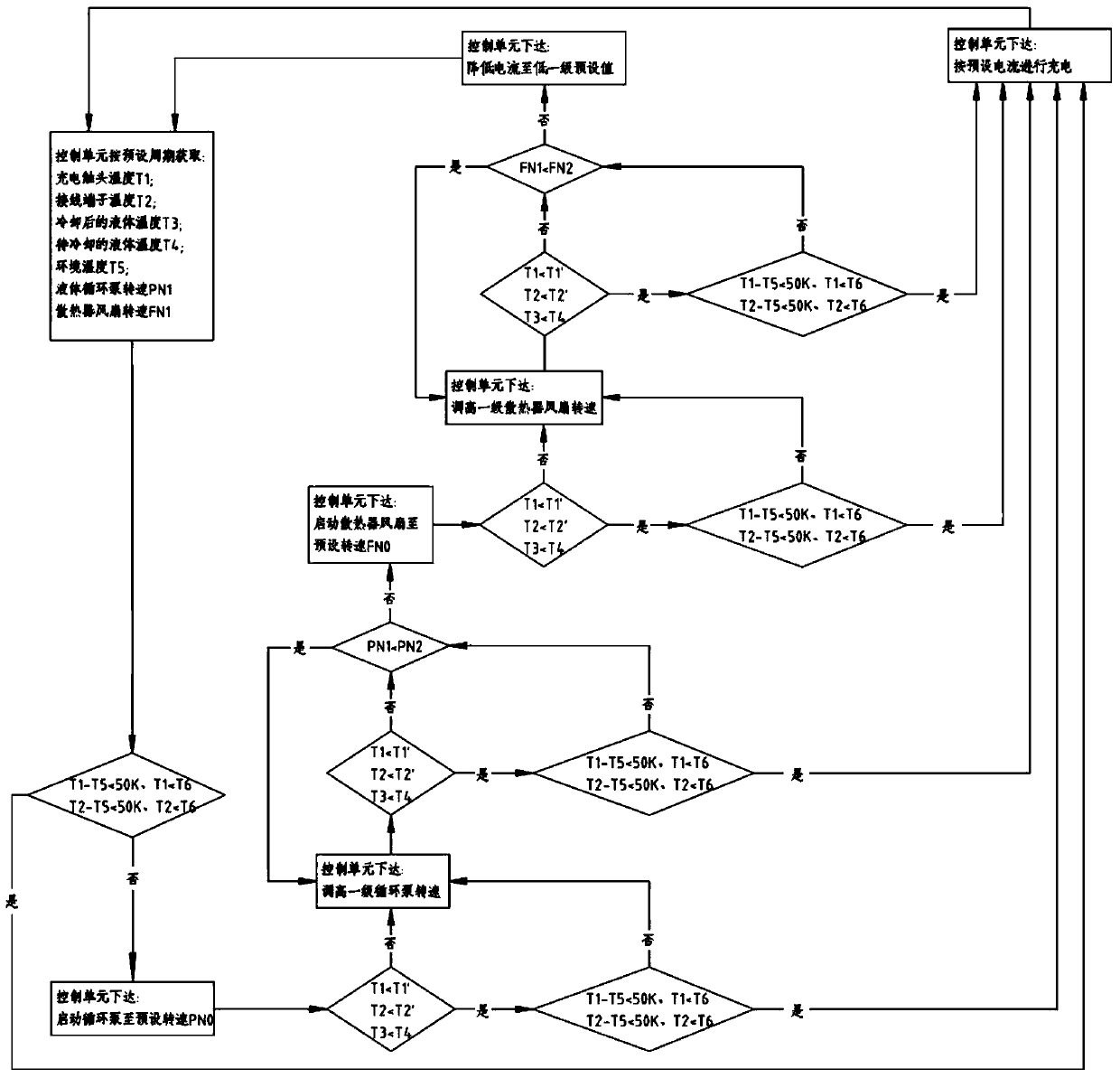

[0057] A control method of a liquid-cooled high-current charging system for electric vehicles is implemented based on the above-mentioned liquid-cooled high-current charging system for electric vehicles, such as figure 2 As shown, it specifically includes the following steps:

[0058] Step 1: The control unit obtains and saves the temperature values returned by the first temperature monitoring device, the second temperature monitoring device, the third temperature monitoring device, the fourth temperature monitoring device, and the fifth temperature monitoring device, and the flow rate returned by the flowmeter Value, the real-time speed PN1 of the liquid circulating pump, and the real-time speed FN1 of the fan of the radiator, and the maximum operating temperature T6 allowed by the system, the preset starting speed PN0 and the maximum speed PN2 of the liquid circulating pump are also stored in the control unit. The preset start-up speed FN0 and the maximum speed FN2 of the fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com