Blank direction recognizing device during feeding process of easy open can necking machine

A technology of direction recognition and cans, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of waste of manual monitoring costs, blank damage, and reverse cans blanks, saving labor costs and reducing economic The effect of loss, material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

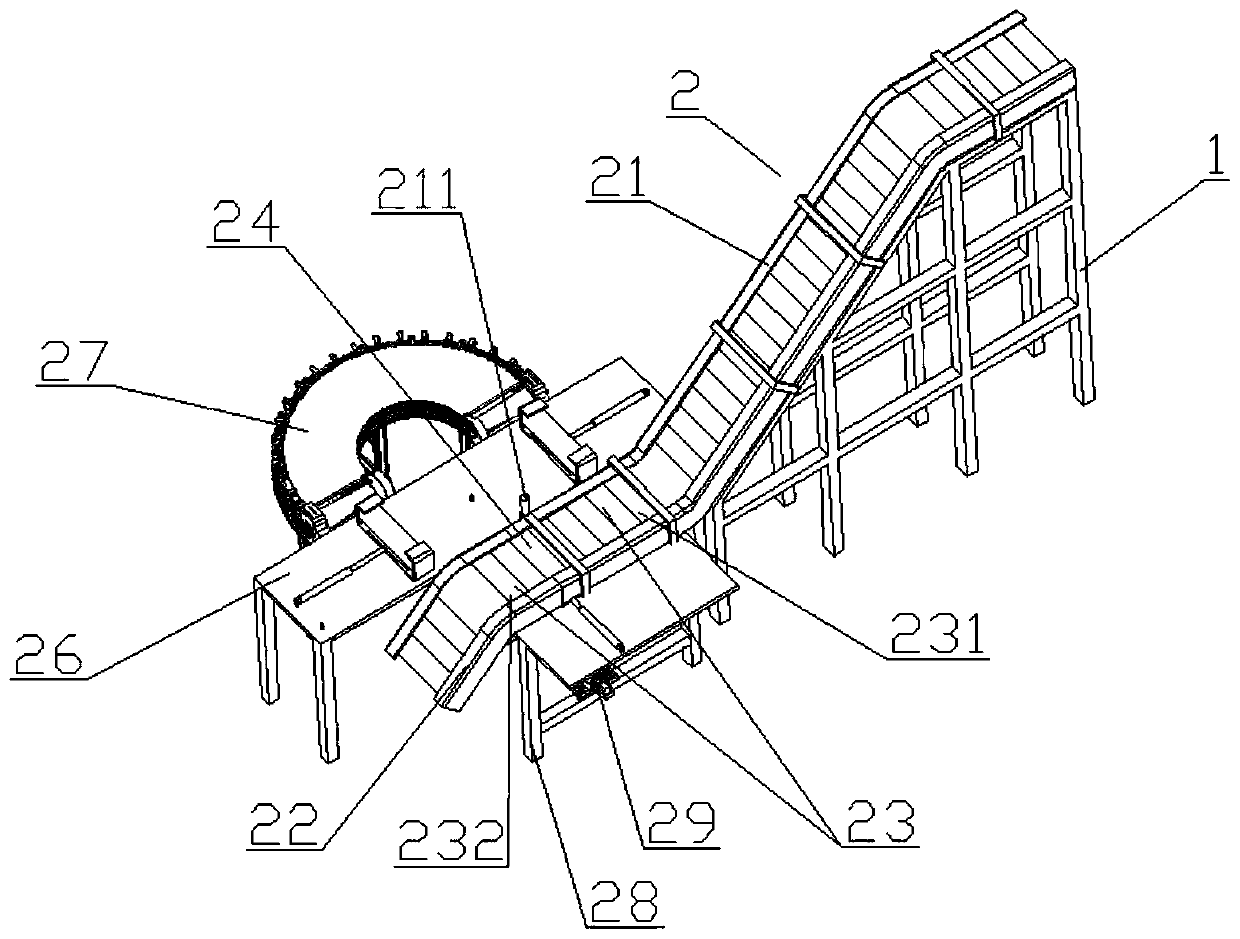

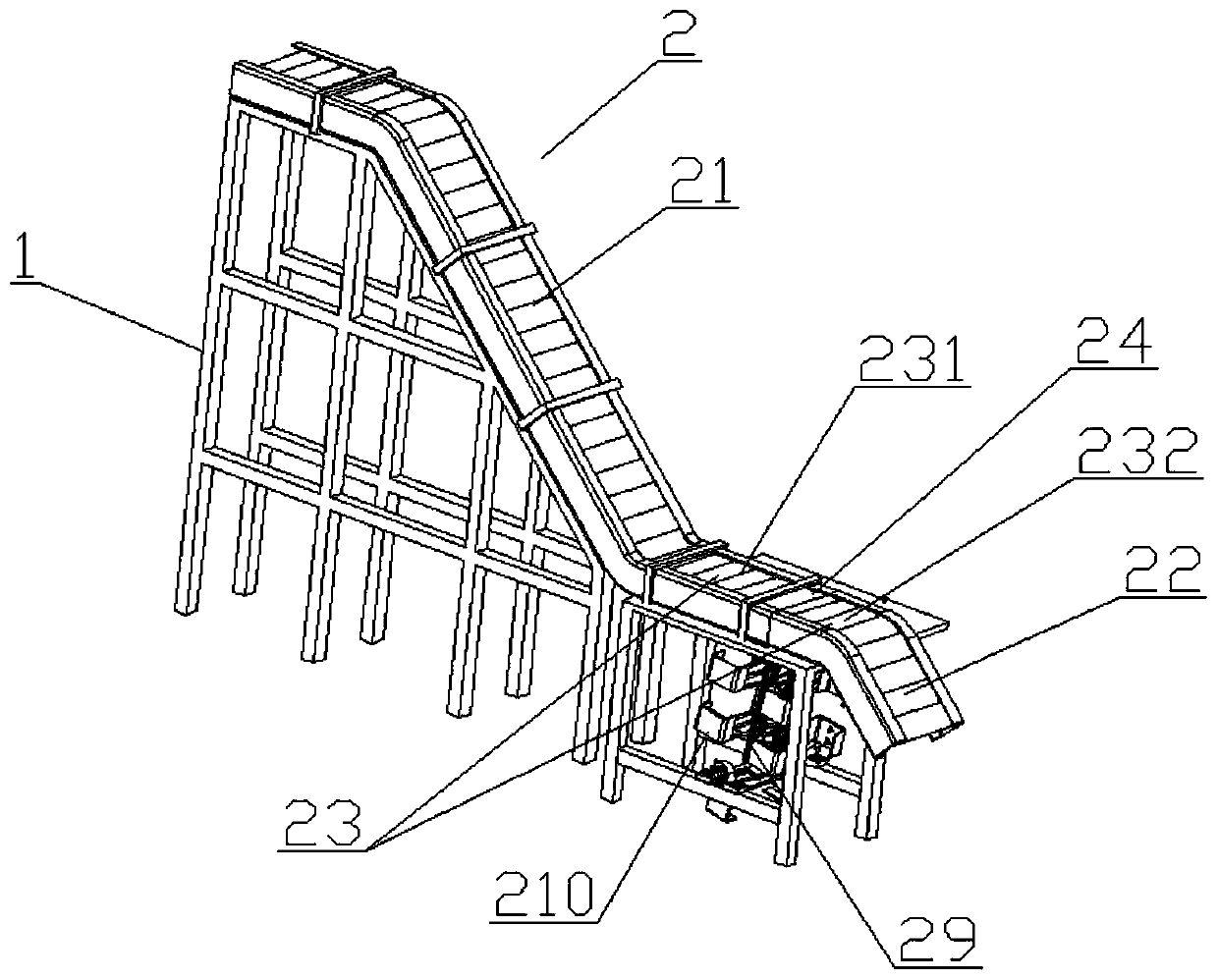

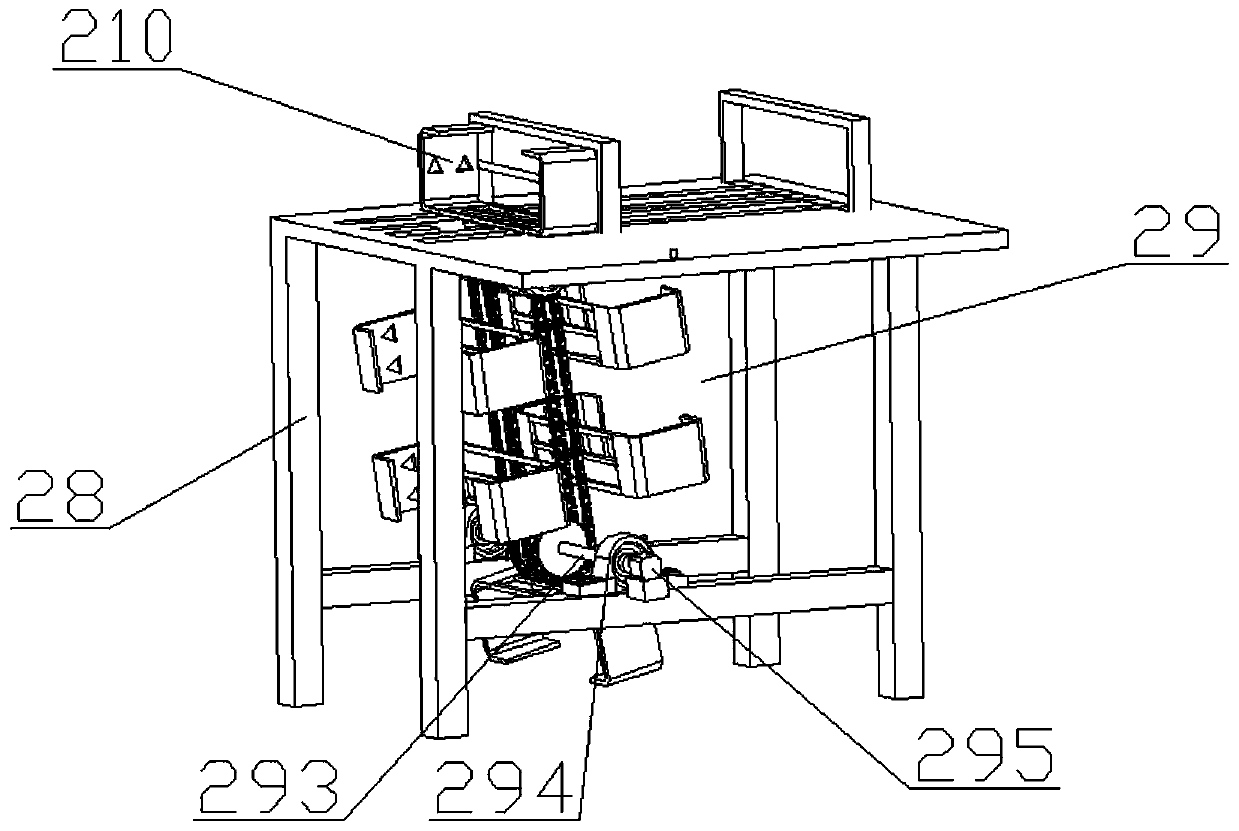

[0038] see figure 1 , a billet direction identification device in the feeding process of a can necking machine, including a support frame 1 and a conveying track 2 arranged on the support frame 1, the conveying track 2 includes an inclined part 21 and a feeding part 22, and the conveying track 2 It also includes a flat part 23, the flat part 23 is arranged between the inclined part 21 and the feed part 22, the flat part 23 includes an upstream section 231 and a downstream section 232, the upstream section 231 includes an upstream section A and an upstream section B, and the upstream section A and the upstream section The inclined part 21 is connected, the upstream section B is provided with a sensor 211, the downstream section 232 includes a downstream section A and a downstream section B, the downstream section B is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com