A preparation method of nano-scale polymer electrolyte for flexible lithium battery

A lithium battery, nano-scale technology, applied in nanotechnology for materials and surface science, electrolyte storage battery manufacturing, non-aqueous electrolyte storage battery, etc., can solve multiple time, energy and electrochemical potential problems, and achieve electrochemical stability Good performance, high ionic conductivity, high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is further described below in conjunction with the accompanying drawings and embodiments.

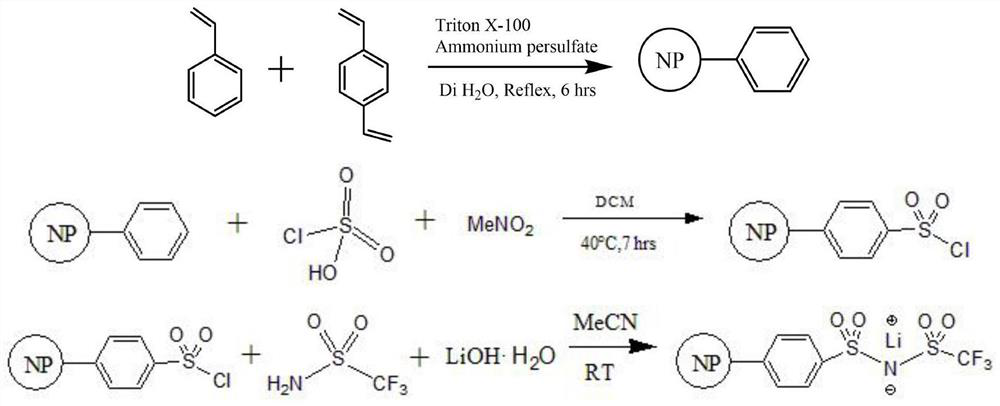

[0041] The present invention proposes a method for preparing a nanoscale polymer electrolyte for a flexible lithium battery, such as Figure 1 As shown, it includes the following steps:

[0042] (1) Synthesis of crosslinked nano-polystyrene (PS).

[0043] Purified styrene is difficult to store. Commercial products often contain added inhibitors (e.g., trace amounts of hydroquinone). Pure styrene is washed with 10% NaOH solution to remove the inhibitor (tert-butyl catechol), then rinsed twice with water, and then mgSO 4 Carry out drying. Using dichloromethane as the solvent, pure styrene was separated by column chromatography. Remove the solvent and vacuum for half an hour. Pure styrene is stored at 0 °C.

[0044] Chloroform is added to vinyl anise ether, the mixture is washed with 10% sodium hydroxide, and the yellow organic matter is rinsed twice with water, wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thermal stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com