An automatic tile cement mortar applicator for building construction

A technology of building construction and cement mortar, which is applied in the direction of construction and building construction, etc., can solve the problems of uneven application and low work efficiency, and achieve the effect of avoiding falling off and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

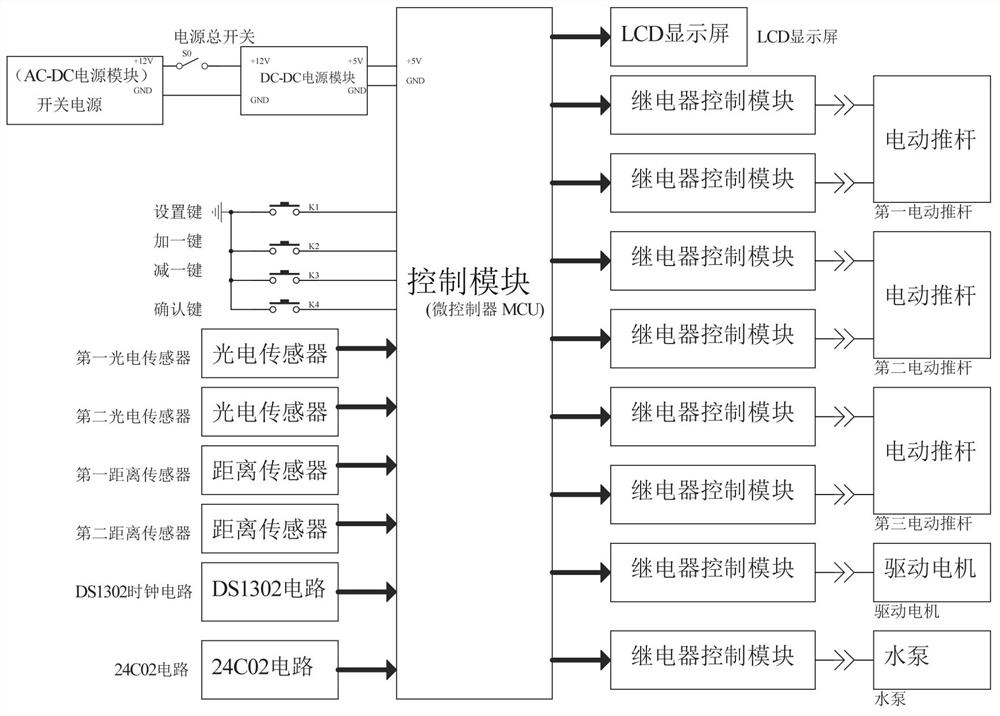

Method used

Image

Examples

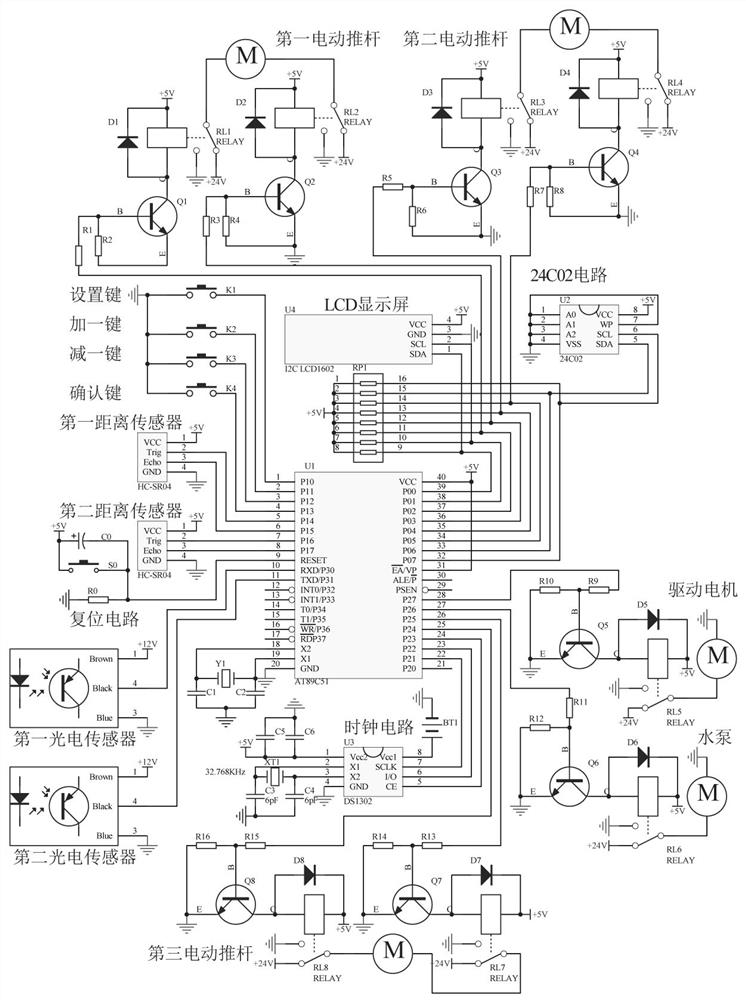

Embodiment 1

[0025] An automatic tile cement mortar applicator for building construction, see figure 1 and image 3 , including a mounting frame 1, a blocking rod 2, a cross bar 6, a pulling device 7, a lifting device 8, a pillar 9, a lower hopper 10, a discharge pipe 11, an elastic sleeve 12 and a smearing pipe 13, and the left side of the mounting frame 1 is fixed The stop rod 2 is connected, the installation frame 1 is connected with the stop rod 2 by welding, the top right side of the installation frame 1 is connected with the cross bar 6, the installation frame 1 is connected with the cross bar 6 by welding, and the top of the cross bar 6 There is a pulling device 7, the pulling device 7 is used to pull the tiles, the top left side of the installation frame 1 is provided with a lifting device 8, the lifting device 8 is used to transport the tiles, the upper part of the installation frame 1 is fixed with a pillar 9, and the lower hopper 10 is installed on the pillar 9 the top, the low...

Embodiment 2

[0033] On the basis of embodiment one, refer to image 3 , also includes a thickness adjustment device 14, the thickness adjustment device 14 includes a mounting plate 141, a third electric push rod 142, a first pressure cylinder 143, a connecting rod 144, a second pressure cylinder 145 and a second distance sensor 146, the lower hopper The right side of the bottom of 10 is connected with a mounting plate 141, the mounting plate 141 is located on the right side of the discharge pipe 11, the third electric push rod 142 is installed on the mounting plate 141, and the mounting plate 141 is connected with the third electric push rod 142 by means of bolt connection , the bottom end of the third electric push rod 142 is equipped with a first pressure cylinder 143, the front side of the third electric push rod 142 is connected with a connecting rod 144, the connecting rod 144 is connected with the smear tube 13 in a rotational manner, and the support 9 is equipped with a second pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com