Gravel Packing Tools while flushing

A gravel filling and edge flushing technology, which is applied in wellbore/well components, production fluids, and earth-moving drilling, etc., can solve the problems of sand spitting in the formation, affecting the sand control effect, and decreasing the permeability of the filling layer. Good construction effect and fast flushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

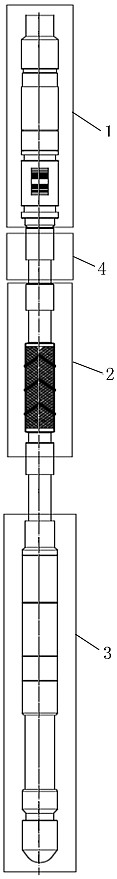

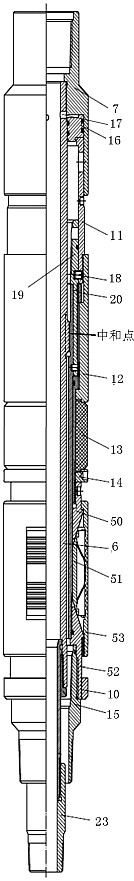

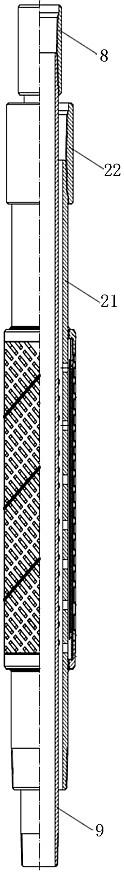

[0030] refer to Figure 1-Figure 5 As shown in the figure, the gravel packing tool is lowered while flushing, including a hanger 1, a sand filter pipe 2, and a bottom flusher 3 connected sequentially from top to bottom. The hanger 1 and the sand filter pipe 2 are connected together through a quick connector 4 , the hanger 1, the sand filter pipe 2 and the inner cavity of the bottom well cleaning device 3 form a circulation channel for filling, and a service string is arranged in the circulation channel.

[0031] Wherein, the service string includes a center pipe 6 located in the cavity of the hanger 1, the upper end of the center pipe 6 is threadedly connected with an upper joint 7, and the outer wall of the center pipe 6 is provided with a screw thread connected with the hanger 1, and the center pipe 6 The lower end of the flushing pipe 9 is connected with the flushing pipe 9 through the back cap, the union and the flushing pipe joint 23. The flushing pipe 9 can be multiple, ...

Embodiment 2

[0036]As a preferred embodiment, it is basically the same as Embodiment 1, except that the quick connector 4 includes an adjusting pipe 41, a union pipe 42 and a connecting pipe 43, and one end of the adjusting pipe 41 is connected to the lower joint 15 of the hanger 1 Connection, the inner wall of the lower end of the union pipe 42 is provided with a limit step 44, the outer side of the other end of the adjustment pipe 41 is threadedly connected with the upper end of the union pipe 42 and forms a compensation space 45 with the limit step 44, and the outer wall of the connecting pipe 43 is provided with a compensation step 46, the compensation step 46 cooperates with the limit step 44 and is movably arranged in the compensation space 45, the outer surface of the connecting pipe 43 is in sliding and sealing contact with the inner wall of the regulating pipe 41, and the lower end of the connecting pipe 43 is connected with the base pipe collar 22. When the hanger 1 is connected t...

Embodiment 3

[0038] As a preferred embodiment, it is basically the same as Embodiment 1, except that two sand retaining valves 47 are arranged in the valve sleeve 32 of the bottom flushing device 3, and one end of each sand retaining valve 47 is elastically The part is connected with the valve sleeve 32 in rotation. The valve sleeve 32 is closed by the double-stage sand retaining valve 47 to ensure safe and reliable closing.

[0039] In addition, the sealing connection sleeve assembly includes a sealing sleeve 48 fixedly connected to the valve sleeve 32 and a connecting sleeve 49 connected to the lower end of the sealing sleeve 48 , and the lower end of the connecting sleeve 49 is connected to the upper end of the short-circuit 33 .

[0040] The guide shoe 35 is threadedly connected to the lower end of the filling sleeve 34 , and the inner wall of the connecting end of the guide shoe 35 is provided with a tapered filling chamber whose inner diameter gradually decreases from the opening to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com