The construction method of split self-propelled formwork trolley for the second lining vault of long-span subway tunnel

A formwork trolley and construction method technology, applied in tunnel lining, tunnel, shaft lining and other directions, can solve the problems of high construction cost, high risk of high-altitude operation, difficult operation of steel bar binding, etc., to control deformation and surface settlement, and to facilitate safety. The effect of emergency rescue and shortening the time of secondary lining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] This embodiment is applied to the two-lining and three-step construction technology of Harbin Metro TJ-12 standard large-span high-risk shallow-buried tunnel. This embodiment overcomes the structural deformation caused by the construction of the secondary lining of the high-risk large-span underground excavation tunnel under complex geological conditions, causing risks such as surface settlement and tunnel instability. The compactness of the secondary lining structure of the tunnel is improved, and the thickness of the reinforced protective layer and the thickness of the main structure of the secondary lining are better controlled.

[0060] The invention provides a construction method for the second lining vault of a large-span subway tunnel using a split self-propelled formwork trolley, including:

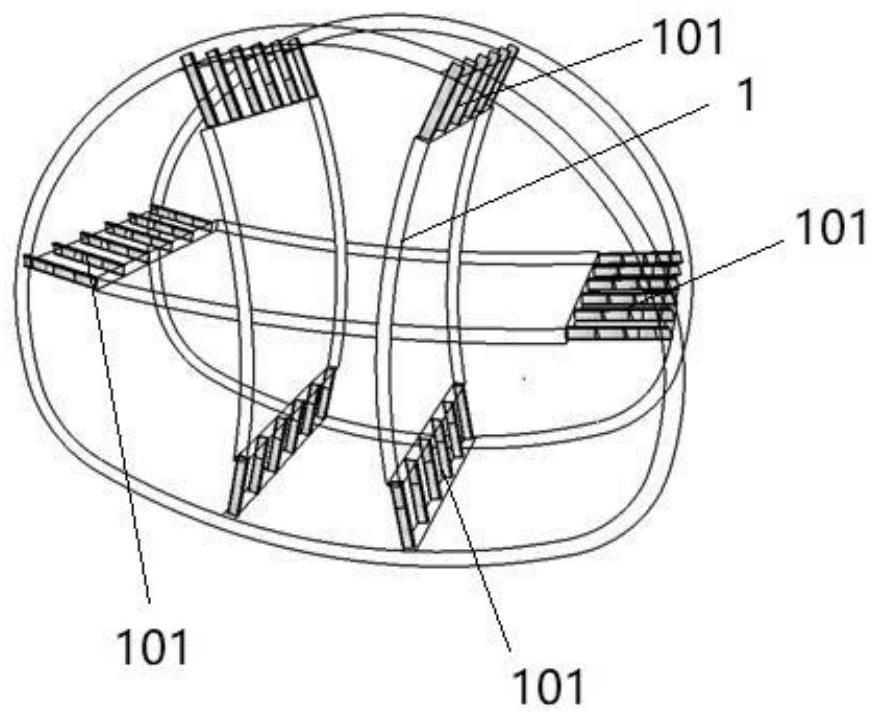

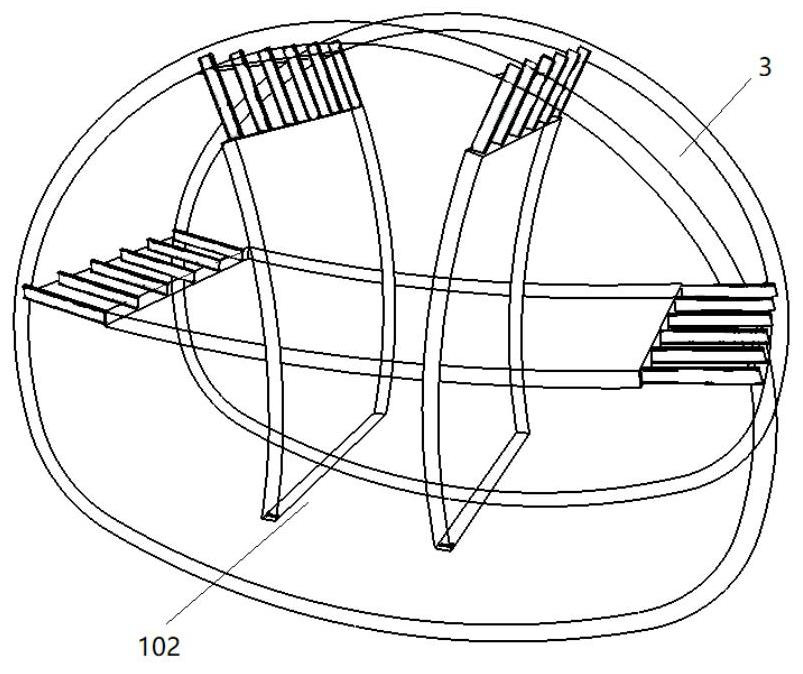

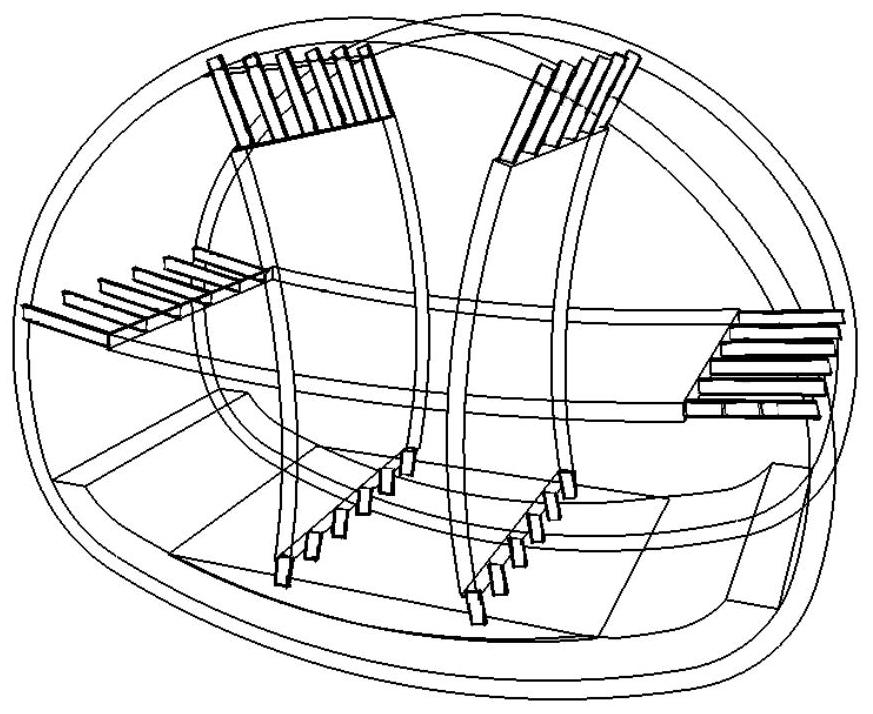

[0061] Step one, such as figure 1 As shown, before the construction, the concrete 101 at the joint between the temporary support 1 and the primary support structure 3 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com