Compressor gas valve set, compressor and refrigerator

A compressor and air valve technology, applied in the field of compressor manufacturing, can solve the problems of low natural frequency of the suction valve tongue, leakage of refrigerant backflow, low refrigeration capacity and energy efficiency of the compressor, etc., so as to improve the refrigeration capacity and energy efficiency, reduce the Inhalation resistance, the effect of improving inhalation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

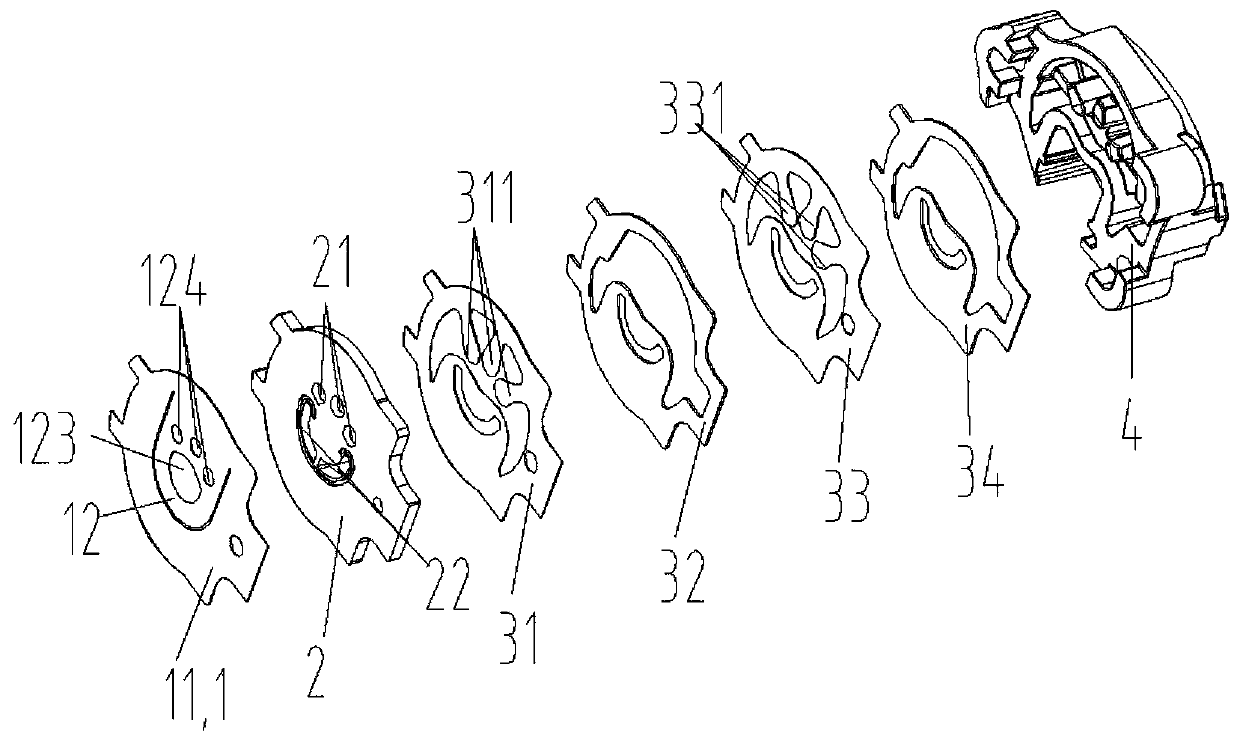

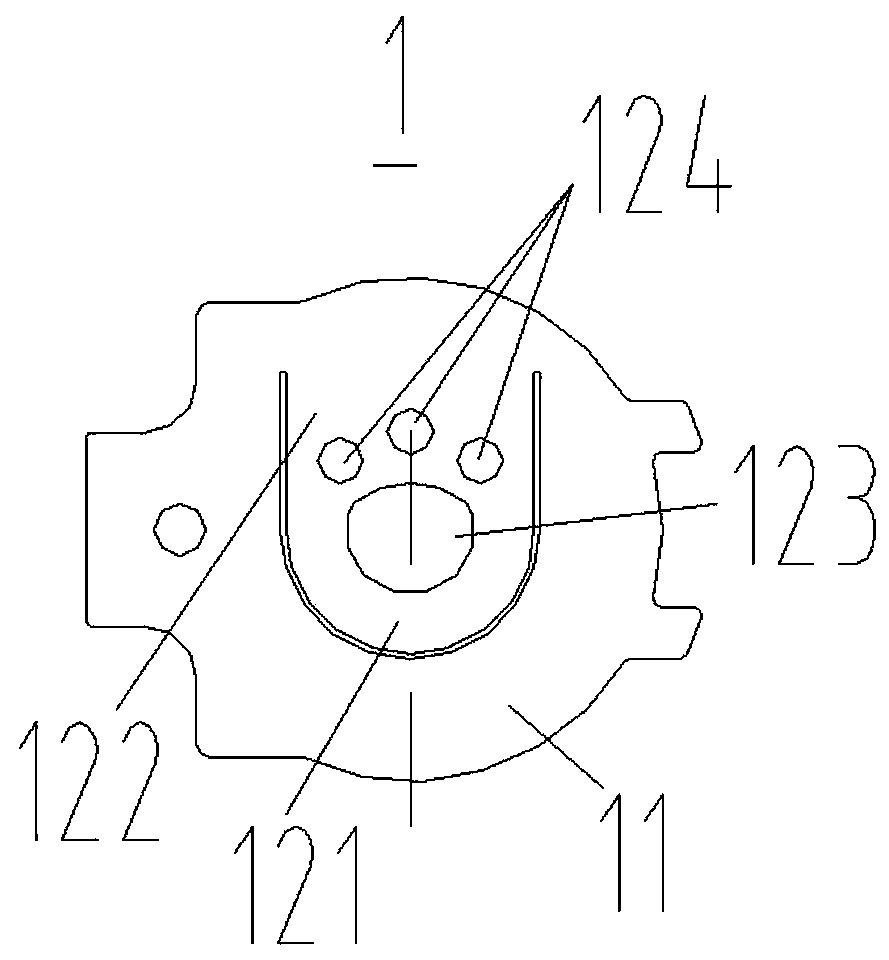

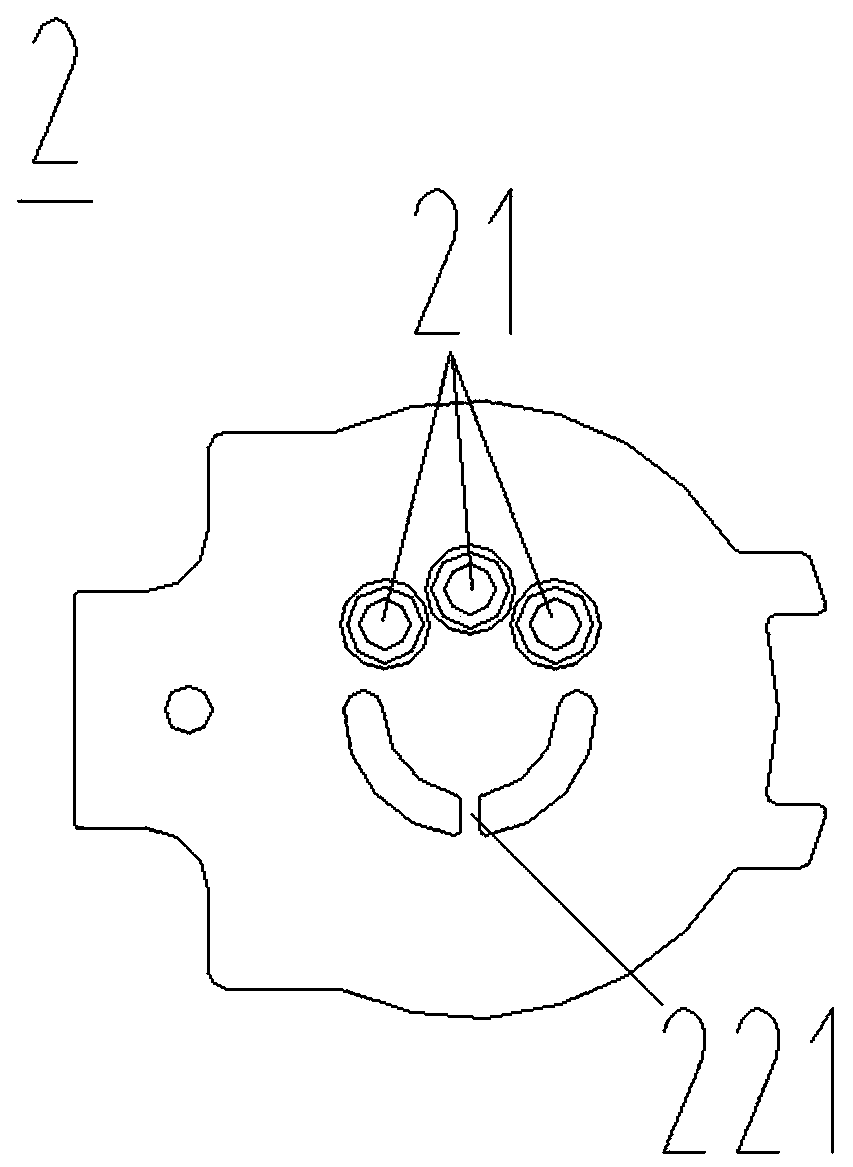

[0025] see in conjunction Figure 1 to Figure 6 As shown, according to the embodiment of the present invention, there is provided a compressor gas valve group, which is used to control the suction and discharge of the piston compressor, including the suction valve plate 1, and the suction valve plate 1 Comprising a body 11, the body 11 is configured with a suction valve tongue 12, the suction valve tongue 12 has a sealing portion 121 covering the suction port of the cylinder and a connection between the sealing portion 121 and the body 11 part 122, the sealing part 121 has a fan ring arc segment, the fan ring arc segment matches the shape of the cylinder suction port (not shown), when the compressor is in the suction process, the cylinder Under the action of internal negative pressure, the arc section of the fan ring will be partially opened toward the air intake port of the cylinder, thereby forming air intake. In this technical solution, since the arc segment of the fan rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com