A water flow state conversion device inside a rigid pipeline

A technology for changing devices and pipelines, which is applied in the direction of rigid pipes, valve operating/release devices, valve devices, etc., and can solve problems such as inability to pass through multi-stage force stilling, ineffective buffering and energy reduction, and inconvenient control of liquid flow, etc., to achieve Significant cushioning energy dissipation effect, remarkable cushioning effect and remarkable wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

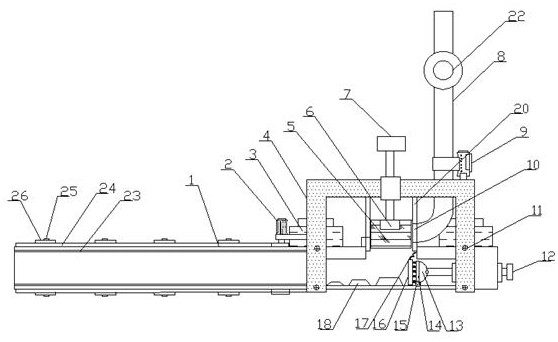

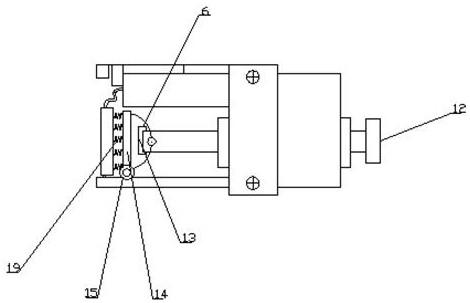

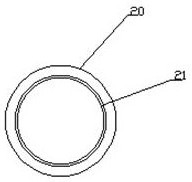

[0024] Such as Figure 1-4 As shown, a water flow state conversion device inside a rigid pipeline includes a water inlet pipe 1, an outlet pipe 8 and a mounting bracket 4, and the water inlet pipe 1 is equipped with a mounting bracket 4 through fastening screws 11, and the water inlet pipe 1 The top output port is welded with a connecting pipe 20, the connecting pipe 20 is provided with a piston 5, the top of the piston 5 is embedded with a bearing 6, and one end of the connecting pipe 20 is connected to the water outlet pipe 8 through the liquid outlet 10, and The outlet pipe 8 runs through the installation bracket 4, and the top end of the installation bracket 4 is equipped with a No. 2 flow velocity sensor 9 through the mounting seat, and a No. 1 flow velocity sensor 2 is installed on one end of the installation bracket 4 through the installation plate. The bottom is equipped with a stilling table 18 through set screws, and one end of the said stilling table 18 is connected...

Embodiment 2

[0038] Such as Figure 1-4As shown, a water flow state conversion device inside a rigid pipeline includes a water inlet pipe 1, an outlet pipe 8 and a mounting bracket 4, and the water inlet pipe 1 is equipped with a mounting bracket 4 through fastening screws 11, and the water inlet pipe 1 The top output port is welded with a connecting pipe 20, the connecting pipe 20 is provided with a piston 5, the top of the piston 5 is embedded with a bearing 6, and one end of the connecting pipe 20 is connected to the water outlet pipe 8 through the liquid outlet 10, and The outlet pipe 8 runs through the installation bracket 4, and the top end of the installation bracket 4 is equipped with a No. 2 flow velocity sensor 9 through the mounting seat, and a No. 1 flow velocity sensor 2 is installed on one end of the installation bracket 4 through the installation plate. The bottom is equipped with a stilling table 18 through set screws, and one end of the said stilling table 18 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com