Heating desorption method of desorption tube

A thermal desorption and thermal desorption technology, which is applied in the preparation of analytical materials, samples for testing, measurement devices, etc., can solve the problems of long sampling process, reduced sensitivity, sample tailing, etc., and achieves simple desorption process and accurate detection results. , the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

[0024] The problem to be solved by the present invention is to provide a heating analysis method for an analysis tube with simple desorption process, accurate detection result, wide application range, short desorption time and greatly improved working efficiency.

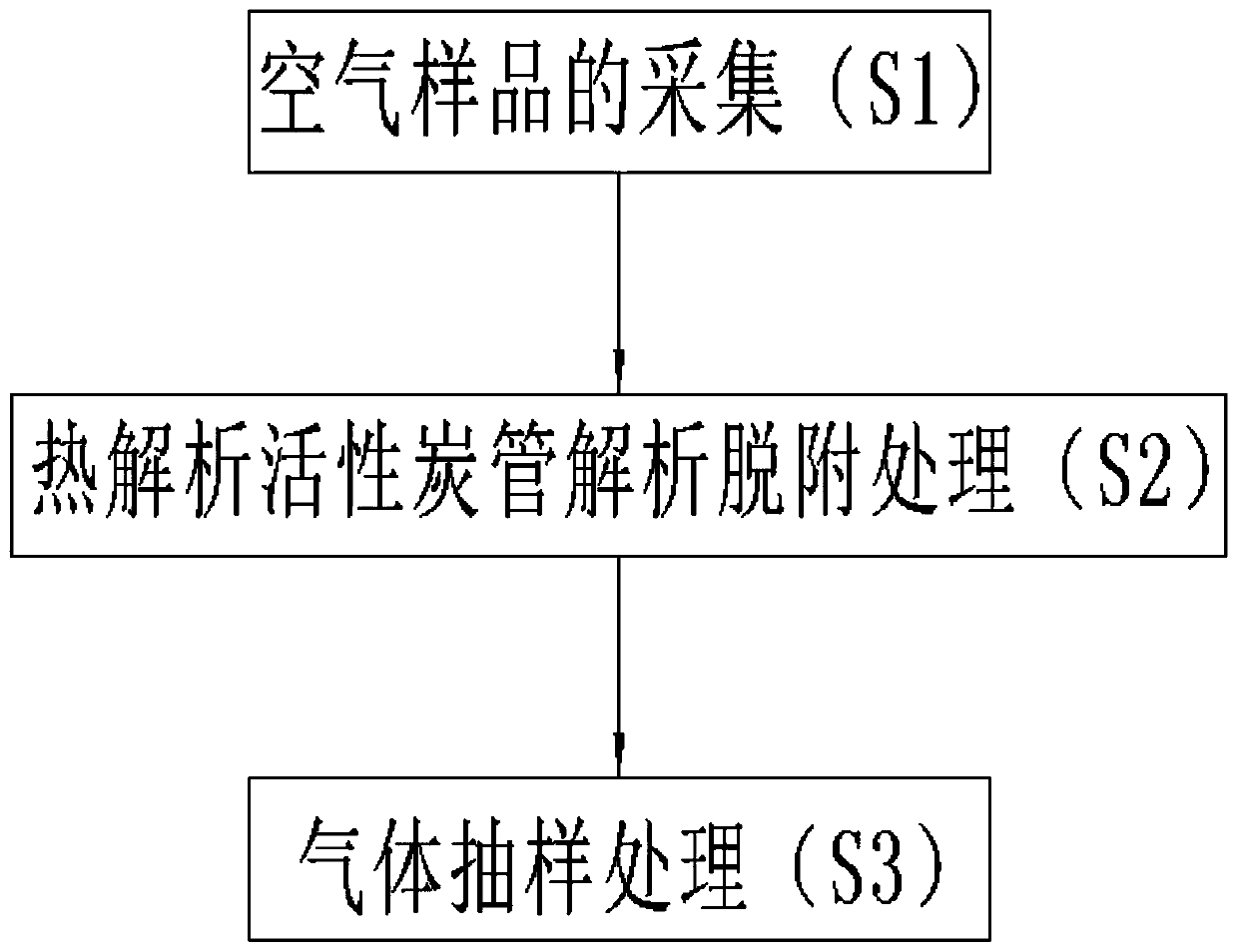

[0025] like figure 1 As shown, in order to achieve the technical purpose, the technical solution of the present invention is that the present invention relates to a heating analysis method for an analysis tube, comprising the following steps:

[0026] S1: First, the air sample is collected and adsorbed on the thermal desorption activated carbon tube;

[0027] S2: Put the thermal analysis activated carbon tube into the analysis instrument to carry out analysis and desorption treatment;

[0028] S3: Inject the gas that has been analyzed and desorbed with a gas sampling needle or a six-way valve. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com