Toilet paper raw material pulp package metal detection system

A technology for metal detection and toilet paper, applied in radio wave measurement systems, measurement devices, geophysical measurements, etc., can solve problems such as expensive, complex and precise structures, and redundant functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

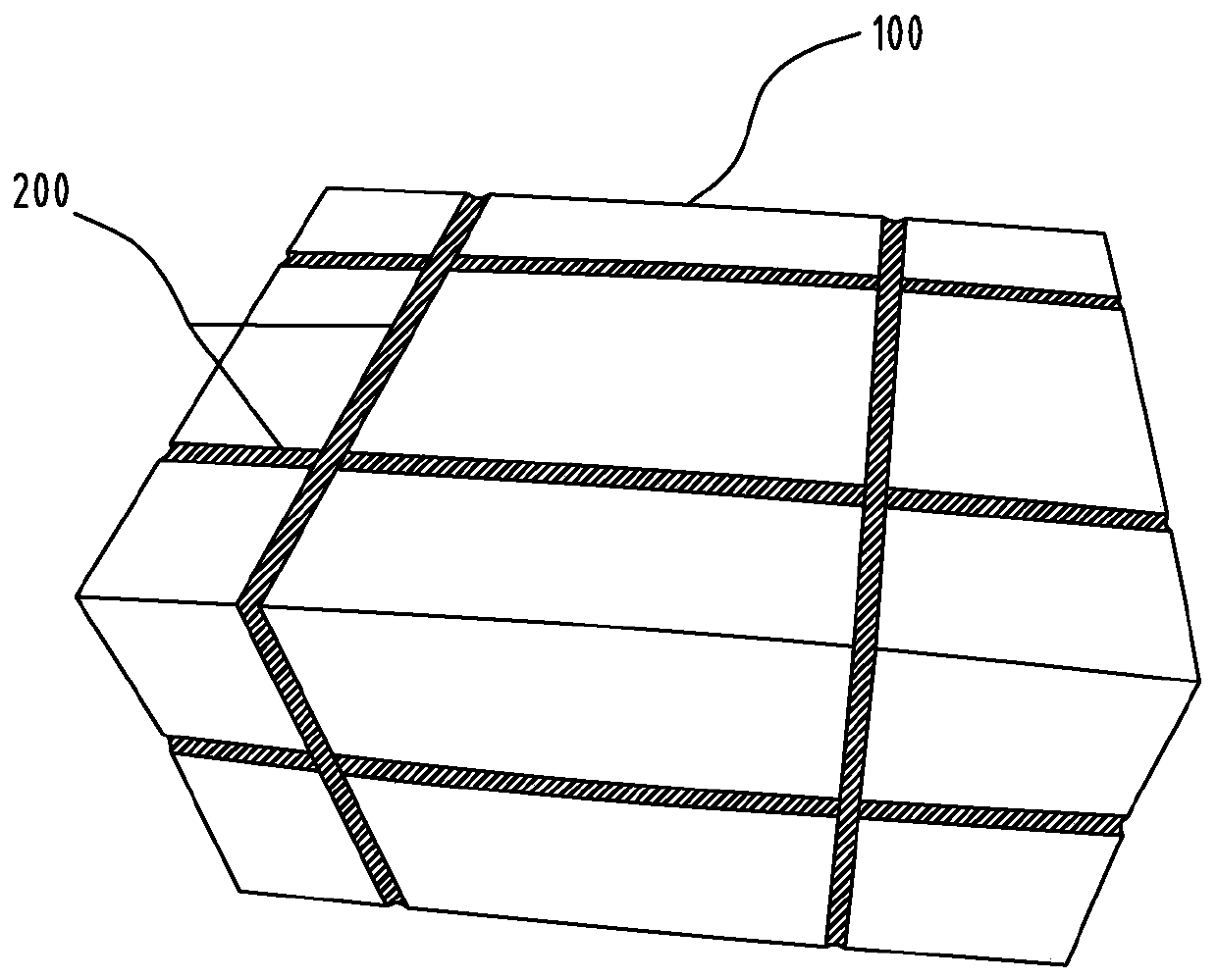

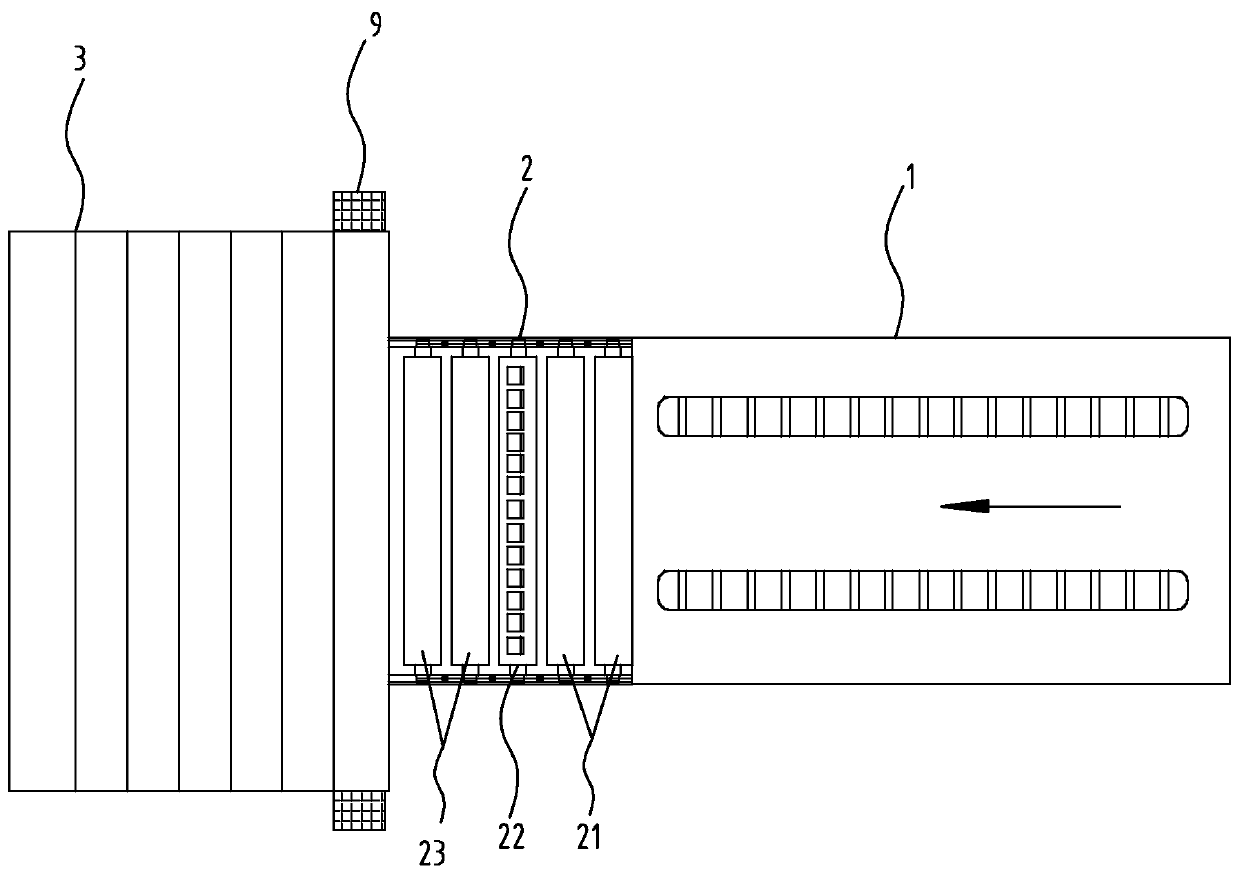

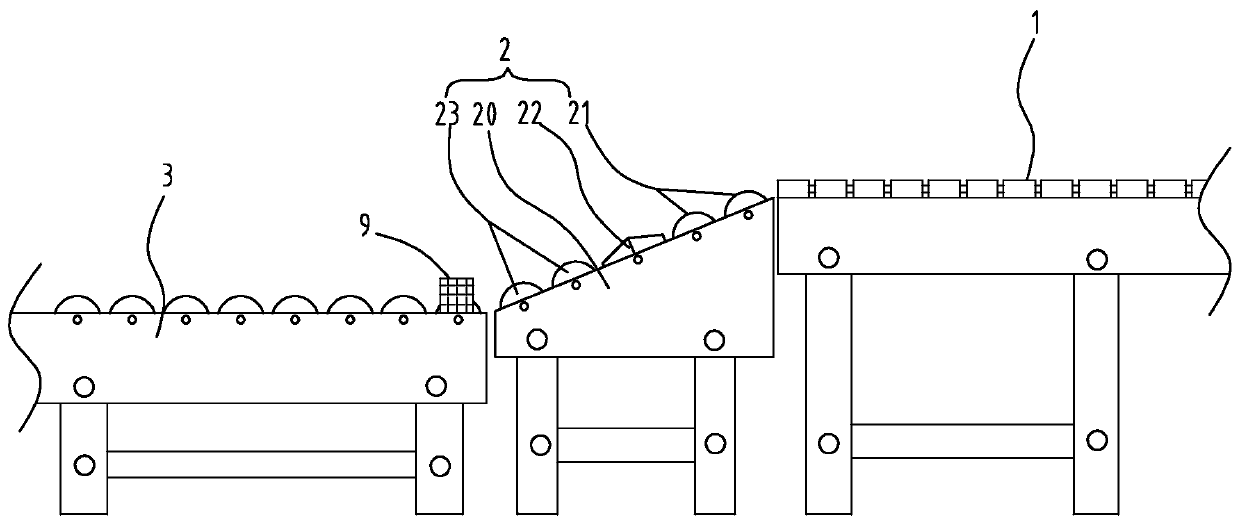

[0020] refer to Figure 2-Figure 5 , this embodiment provides a toilet paper raw material paddle package metal detection system for detecting toilet paper raw material paddle packages, including a chain conveyor 1, a plate chain conveyor 2, a transition roller frame 3, a DCS controller 4, a host computer 5, A / D analog-to-digital conversion device 6 , DC power supply module 7 , wiring terminal block 8 , through-beam photoelectric sensor 9 , sound and light alarm 10 , and on-site man-machine interface 11 . The chain conveyor 1 and the plate chain conveyor 2 are respectively connected to the DCS controller 4 through the A / D analog-to-digital conversion device 6, and the upper computer 5 and the DCS controller 4 are connected in communication, and the upper computer 5 is connected to the DCS controller 4. Setting the conveying speed of the chain convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com