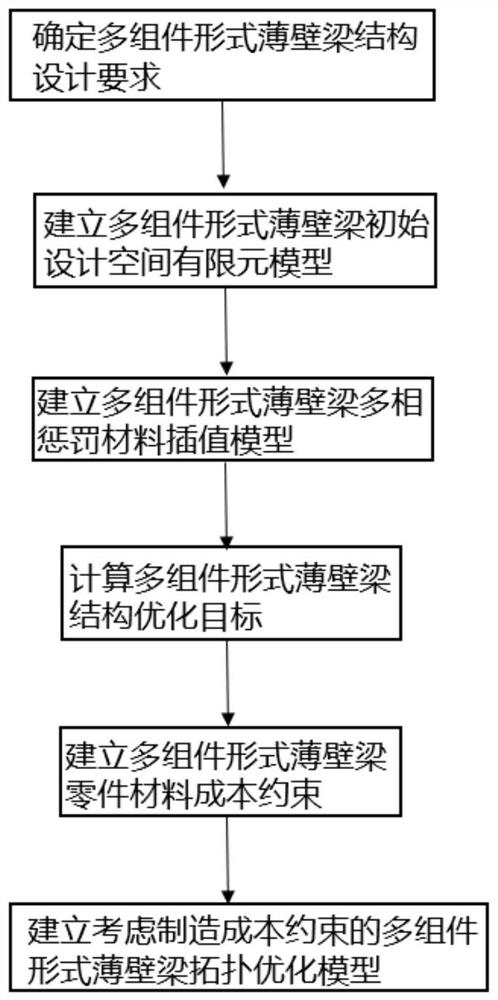

Design method of multi-component thin-wall beam structure considering manufacturing cost

A manufacturing cost and structural design technology, applied in the field of multi-component thin-walled beam structure design, can solve the problems of poor manufacturability of thin-walled beams, poor economical and process feasibility, complex shape of single-component thin-walled beams, etc., and achieve the goal of improving economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

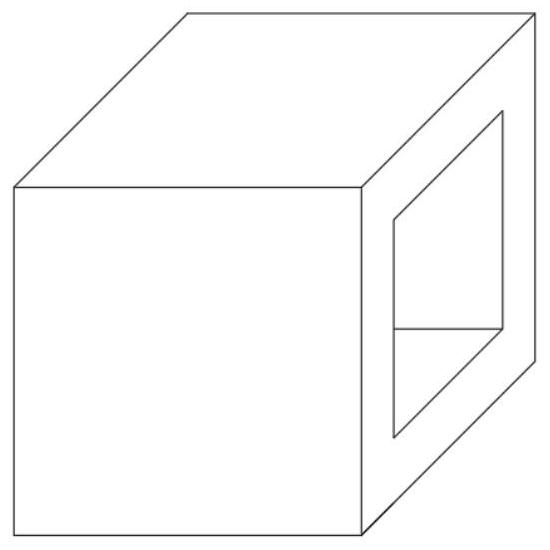

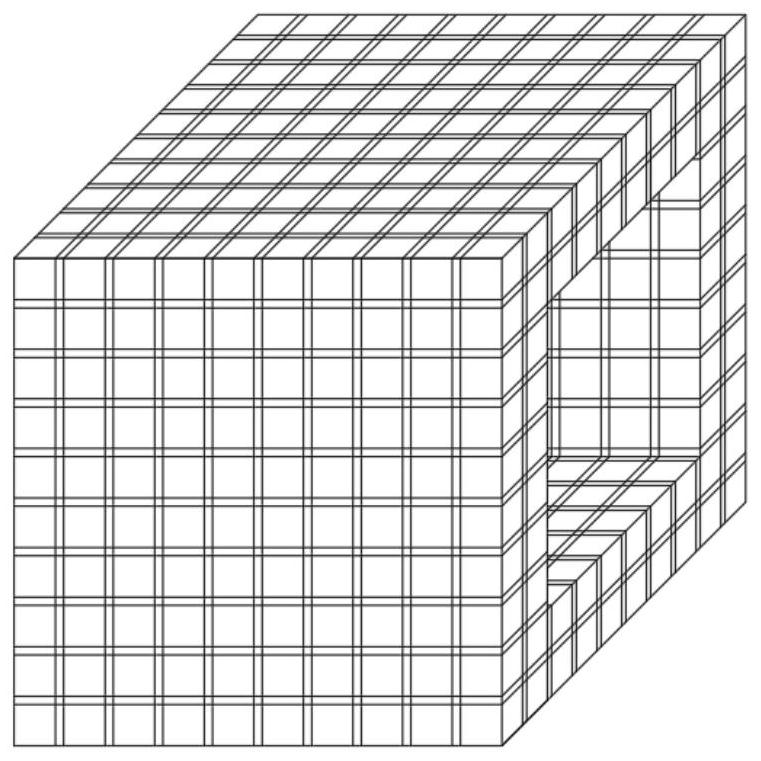

[0175] Example: An example is given below to verify the effectiveness of this method

[0176] Based on the design method described in the specification, the present invention writes a program code for the optimal design of a multi-component thin-wall beam structure in MATLAB. We use the present invention to solve the thin-walled beam under the condition of the cantilever beam loaded at the lower end, and finally obtain the thin-walled beam structure in the form of multiple components.

[0177] First, establish a thin-walled beam structure with a geometric size of 10×10×10, a hollow square hole with a diameter of 6×6, an elastic modulus unit of 1, a Poisson’s ratio of 0.3, the preset number of components is set to K=3, and the volume constraint limit is set V * Set to 0.5, part material cost limit Volume (k) set to 10 9 , the initial values of the element density ρ and the component specific gravity fraction m are respectively set as the volume constraint limit V * and 1 / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com