Boiler operation parameter processing method and device, boiler controller and medium

A technology for operating parameters and parameter processing, applied in neural learning methods, instruments, biological neural network models, etc., can solve problems such as technical faults, increase in boiler failure rate, and decline in economic benefits of boiler energy supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

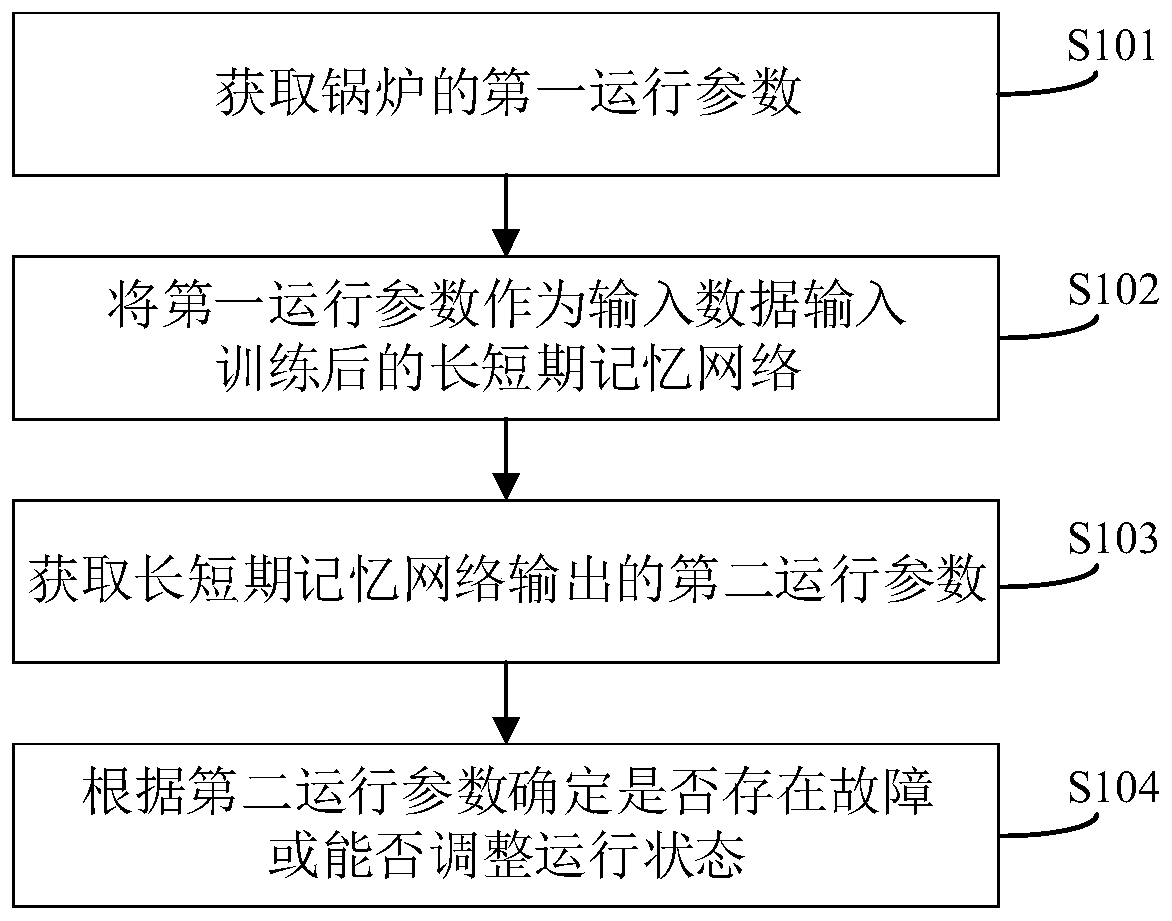

[0081] See figure 1 , figure 1 A flow chart of a method for processing boiler operating parameters provided in an embodiment of the present application, which includes the following steps:

[0082] S101: Obtain the first operating parameter of the boiler;

[0083] This step aims at obtaining the first operating parameter of the boiler, which is collected when the boiler is in an actual operating state. Specifically, the first operating parameter can be obtained through feedback or reading from various sensors and indicator light devices arranged on the boiler, and it is not specifically limited here.

[0084] S102: Input the first operating parameter as input data into the trained long-short-term memory network;

[0085] Wherein, the long-short-term memory network is pre-trained using the historical first operating parameters of the boiler in the historical operating process.

[0086] On the basis of S101, this step aims to input the first operating parameter as input data...

Embodiment 2

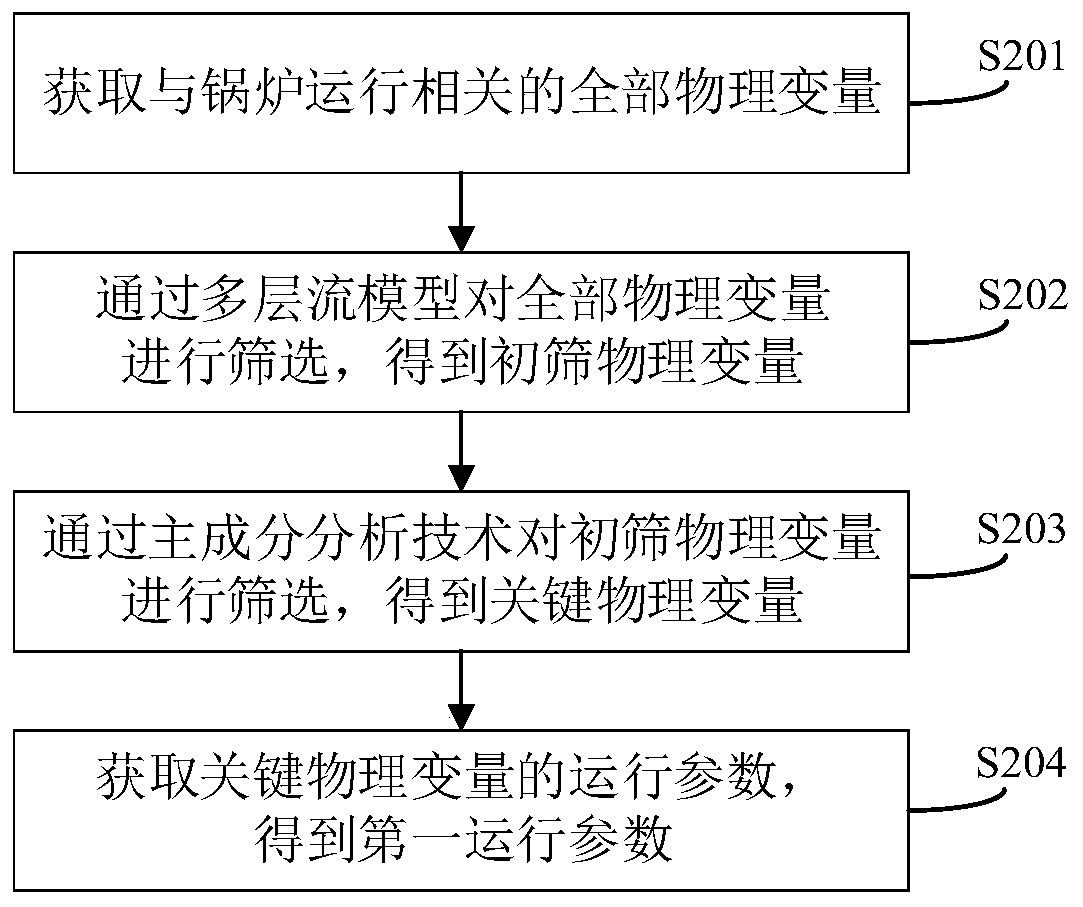

[0097] On the basis of Embodiment 1, considering the actual use state of the heating boiler, there may be as many as 200 parameters that can be used as input parameters, but if the parameter weights of these 200 different types of boiler physical variables are input as input parameters The long-short-term memory network not only requires extremely long calculation time, but also considers that a considerable part of the network is not highly correlated with the second operating parameter to be used as an output parameter, and the calculation is of little significance, which will reduce the calculation efficiency.

[0098] Therefore, on the basis of Embodiment 1, this embodiment passes figure 2 The flow chart shown provides a flow chart of a method for obtaining the first operating parameter, which specifically includes the following steps:

[0099] S201: Obtain all physical variables related to boiler operation;

[0100] S202: Screen all the physical variables through the mu...

Embodiment 3

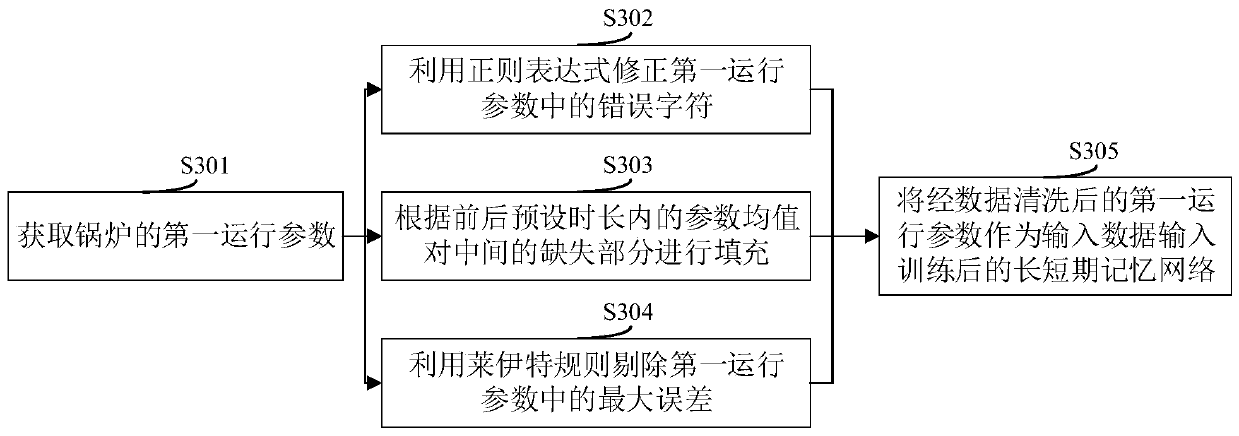

[0124] On the basis of any of the above embodiments, this step considers that the first operating parameter containing multiple types of data may cause problems such as the existence of wrong characters, loss, and invalid data due to various reasons. Based on the image 3 The flow chart of a data cleaning method shown includes the following steps:

[0125] S301: Obtain the first operating parameter of the boiler;

[0126] S302: Using regular expressions to correct wrong characters in the first operating parameter;

[0127] S303: Fill in the missing part in the middle according to the mean value of the parameters within the preset duration before and after;

[0128] For example, for missing data, it is filled with the mean value of the data of 60 seconds before and after.

[0129] S304: Eliminate the maximum error in the first operating parameter by using the Leite rule;

[0130] S305: Input the first operating parameter after data cleaning into the trained long short-term ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com