Overvoltage and low-voltage sensing automatic gear shifting transformer

A transformer and low-voltage technology, applied in the field of transformer supporting facilities, can solve the problems of low-voltage or over-voltage, inconvenient maintenance and high cost, and achieve the effects of timely action response, convenient maintenance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

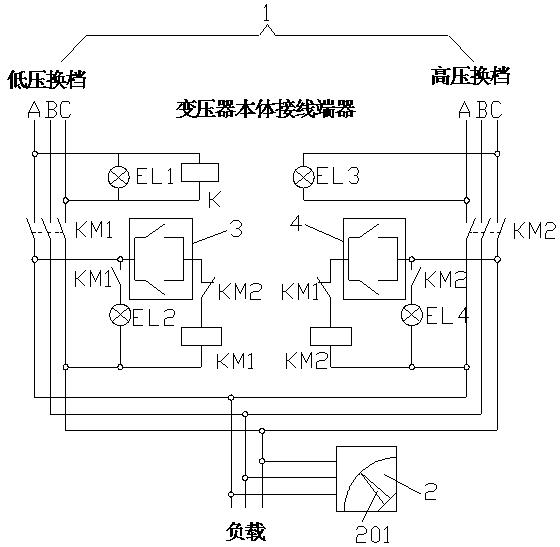

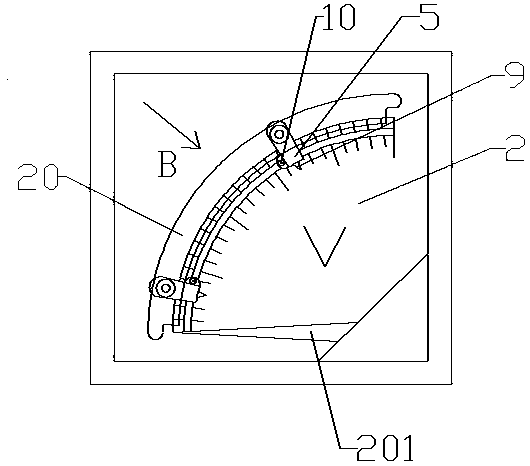

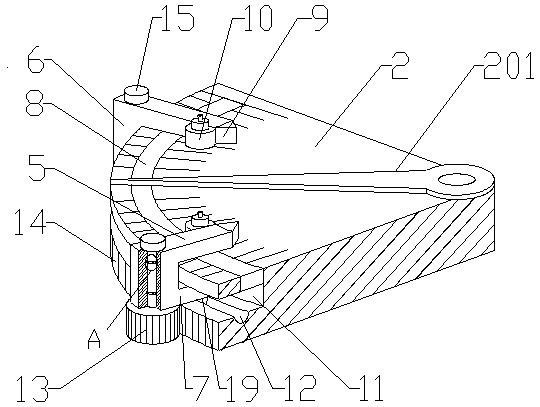

[0030] Accompanying drawing is the specific embodiment of the present invention. like Figures 1 to 5 As shown, the sensed overvoltage and low-voltage automatic shifting transformer includes a transformer body 1 and a voltmeter 2 for detecting the voltage of the transformer body 1. The terminals of the transformer body 1 are electrically connected to the low-voltage shifting module 3 and the high-voltage shifting module 3 respectively. The gear module 4; the low-voltage shift module 3 and the high-voltage shift module 4 form an interlock through the contactor, the contactor is the contactor KM1 and the contactor KM2, and the low-voltage shift module 3 is formed by the normally closed contact between the low-voltage start module and the contactor KM2 The high-voltage shift module 4 is composed of the high-voltage starting module, the normally closed contact of the contactor KM1 and the coil of the contactor KM2 in series; the low-voltage starting module and the high-voltage sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com