Chip flexible heat transfer mechanism

A chip and flexible technology, applied in the field of chip flexible heat transfer mechanism, can solve problems such as poor heat dissipation of the chip and limited deformation of the heat conduction pad, and achieve the effect of solving chip overvoltage or poor heat transfer, good effect, and improved heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

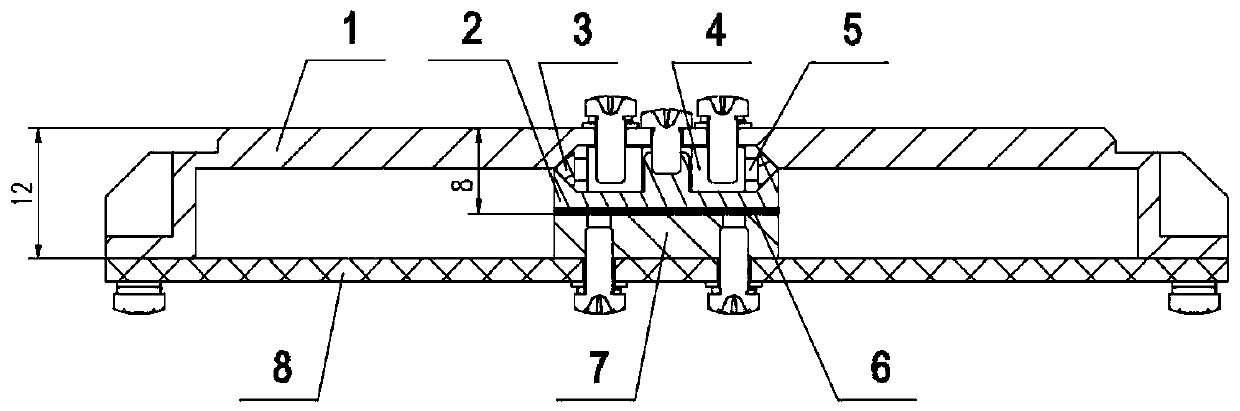

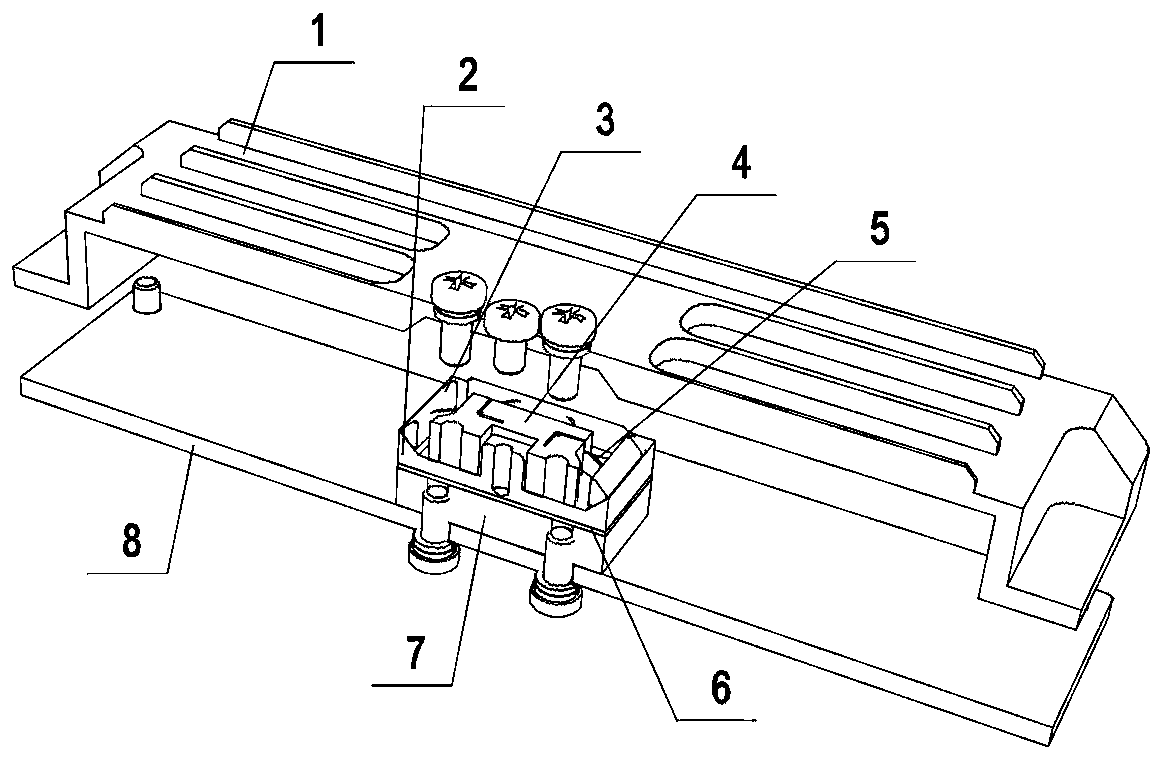

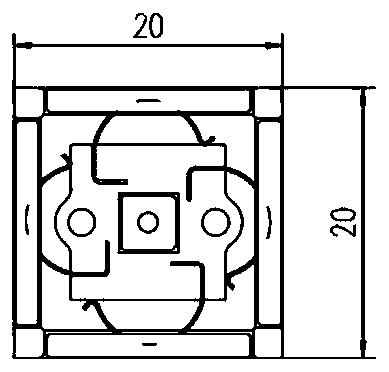

[0014] like figure 1 and figure 2 The shown chip flexible heat transfer mechanism is installed on the chip 7 and the heat conducting pad 6. The heat transfer mechanism includes a cold plate 1 and a heat conducting block 2 arranged up and down, and adjustable bolts are used between the cold plate 1 and the heat conducting block 2. Connecting, at the edge of the butt joint of the cold plate 1 and the heat conduction block 2, there are symmetrically arranged triangular inclined plane areas in multiple directions with the heat conduction block 2 as the center, and an elastic triangular prism sliding mechanism is installed in each triangular inclined plane area, which slides through the elastic triangular prism. The sliding of the mechanism in the triangular slope area realizes flexible interconnection with the vertical heat transfer path of the chip 7 .

[0015] The triangular prism sliding mechanism is constituted by the triangular prism sliding block 3 arranged laterally at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com