Dual release dosage form capsule and methods, devices and systems for making same

A dual-release, capsule technology, used in capsule delivery, packaging, pharmaceutical formulations, etc., can solve the problem of high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

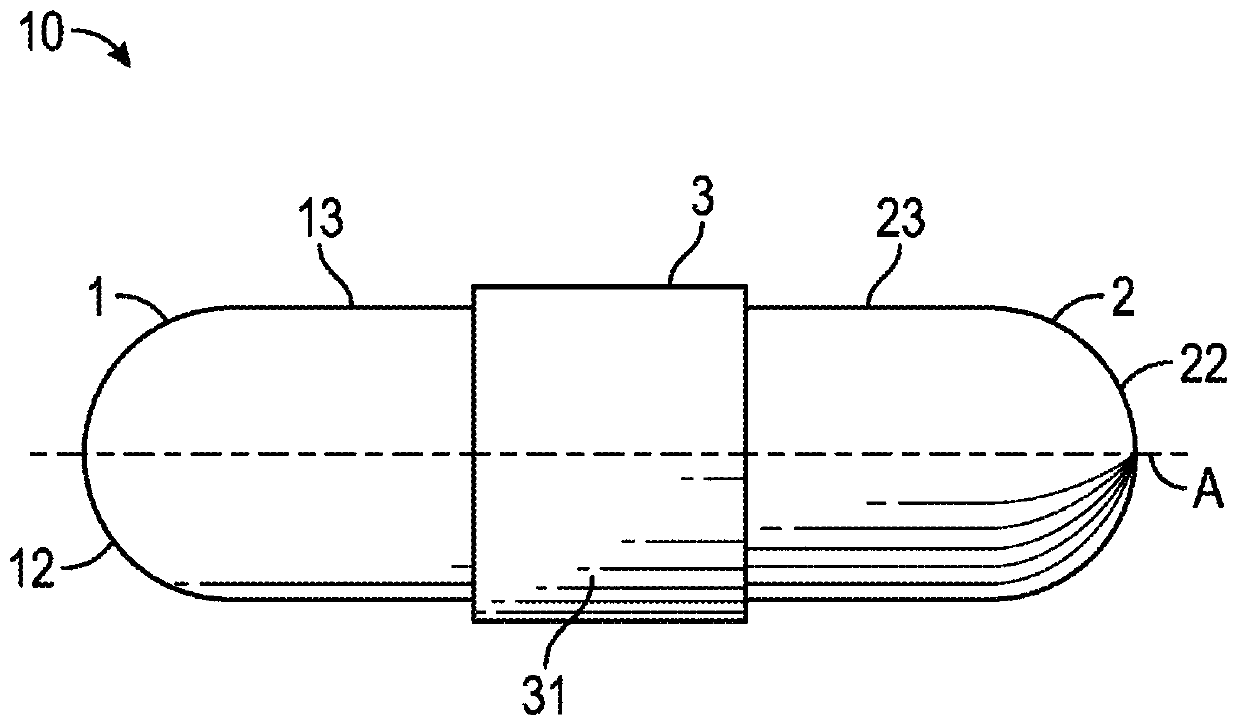

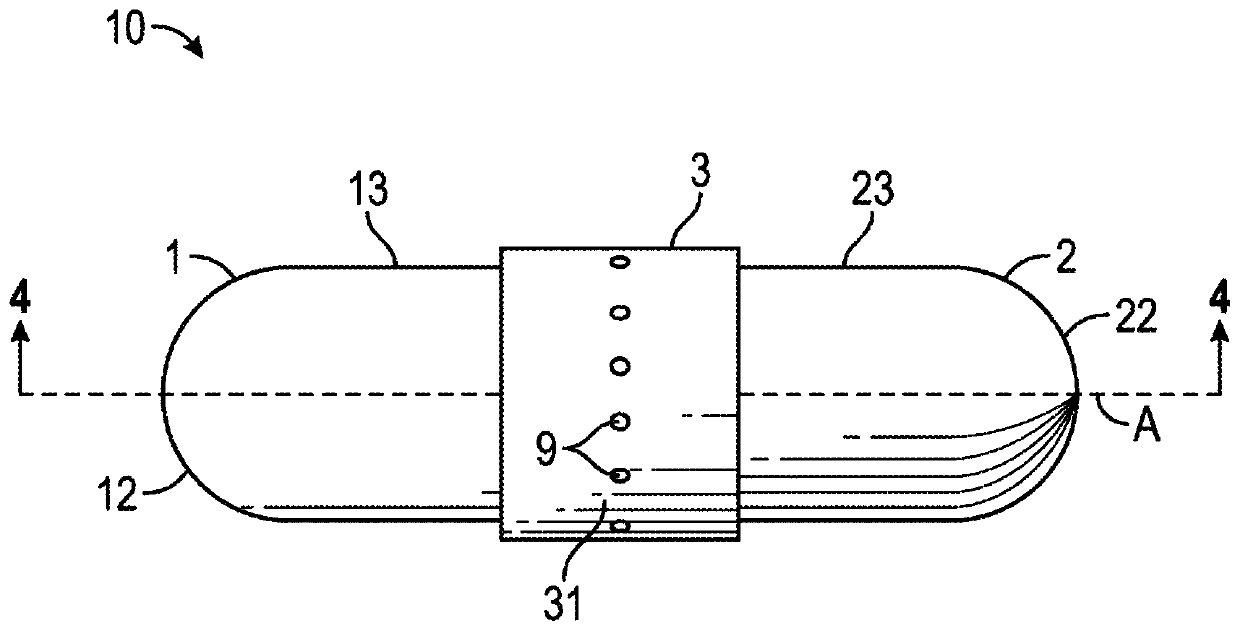

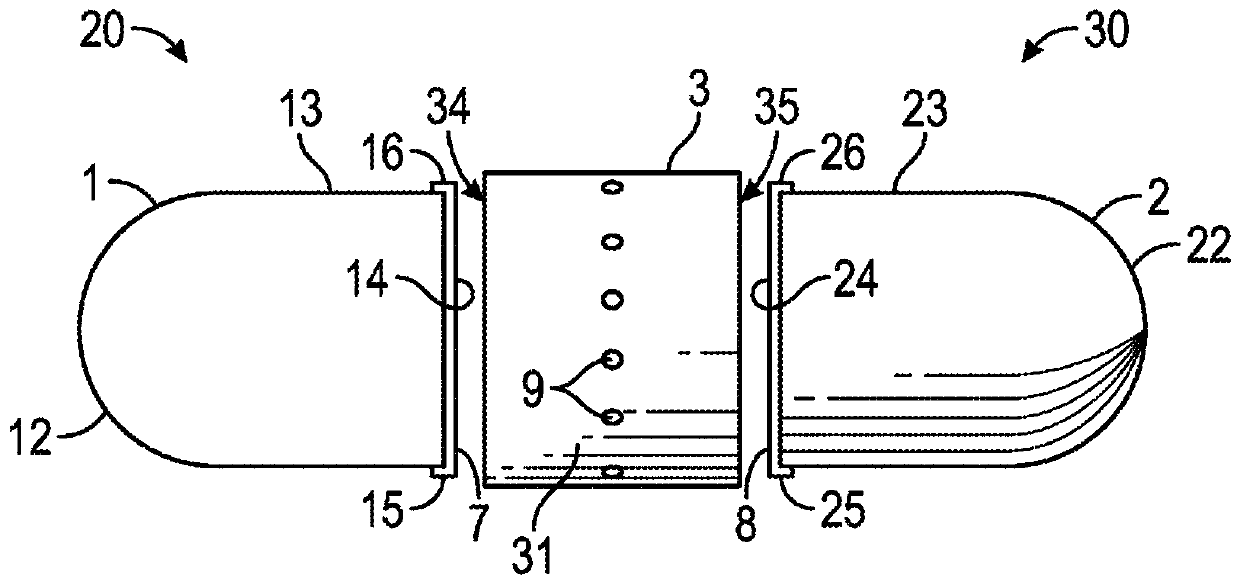

[0030] Provided herein is a dual release dosage capsule and a method for making the same. A dual-dose capsule comprises two capsule halves, each capped at one end to form a capsule member. For example, each capsule member may be filled with a different filling material. A drawstring is used to couple the two capsule members together to form a two-dose capsule. The strap is applied to the capsule members to form a cavity between the capsule members, the cavity being adjacent to the outer surface of the capsule member cover and the inner surface of the strap. The strap includes one or more apertures exposing the third chamber to the environment. For example, the holes allow fluid to move into the chamber between the capsule members, thereby facilitating the release of the fill material in a predetermined manner.

[0031] More specifically, in some examples, the caps of each capsule member may be made of different materials, such as materials that dissolve at different rates. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com