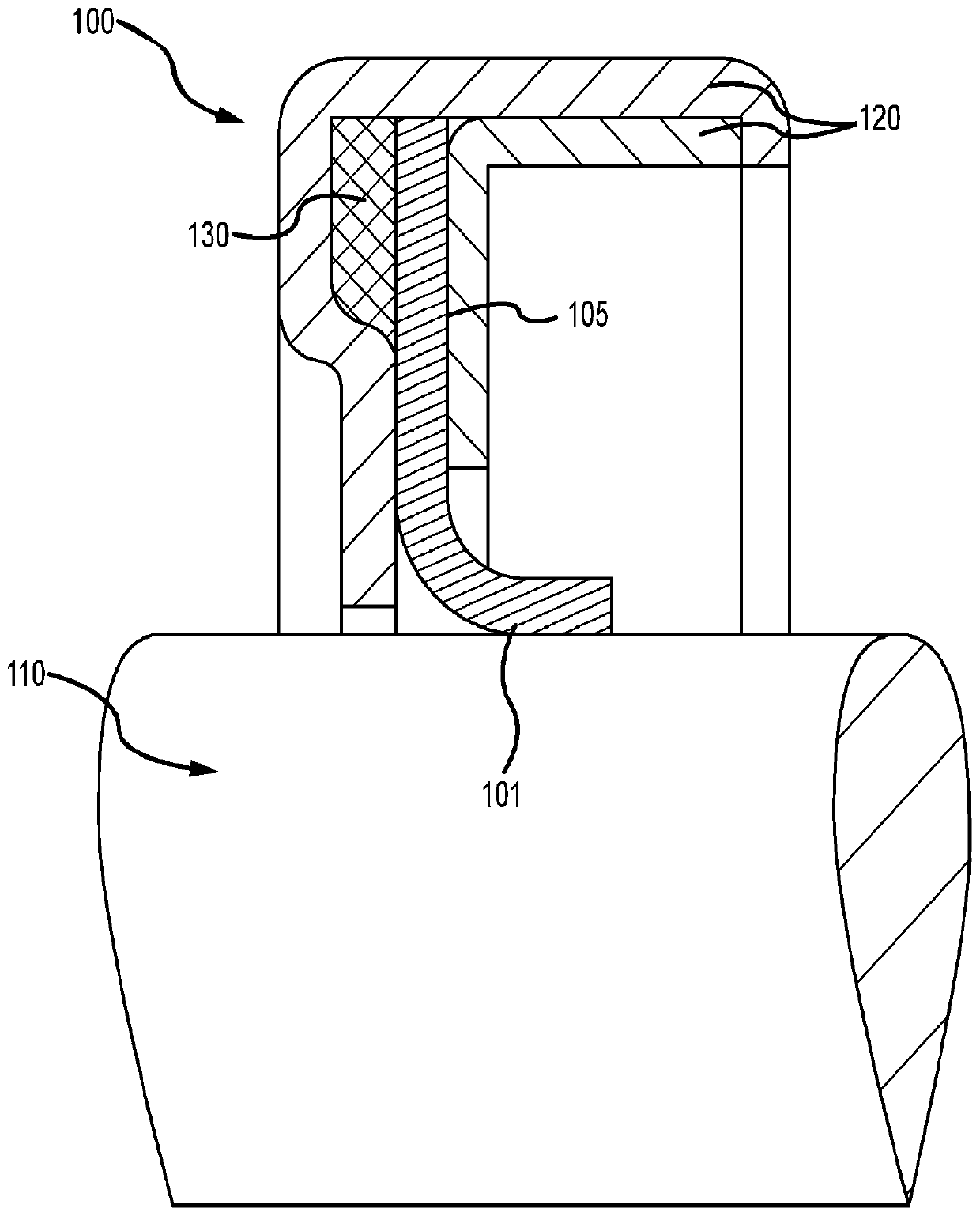

Multi-layered PTFE radial lip seal

A technology of PTFE and lip seals, which is applied in sealing, engine sealing, packaging, etc., can solve the problems of increasing the friction coefficient and the abrasion effect of radial lip seals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

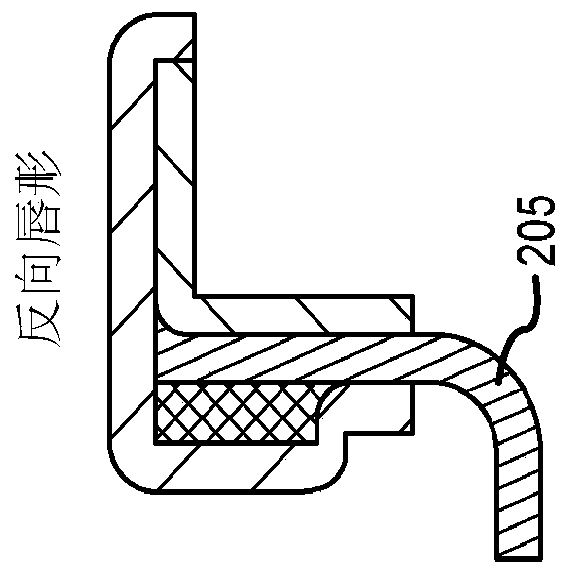

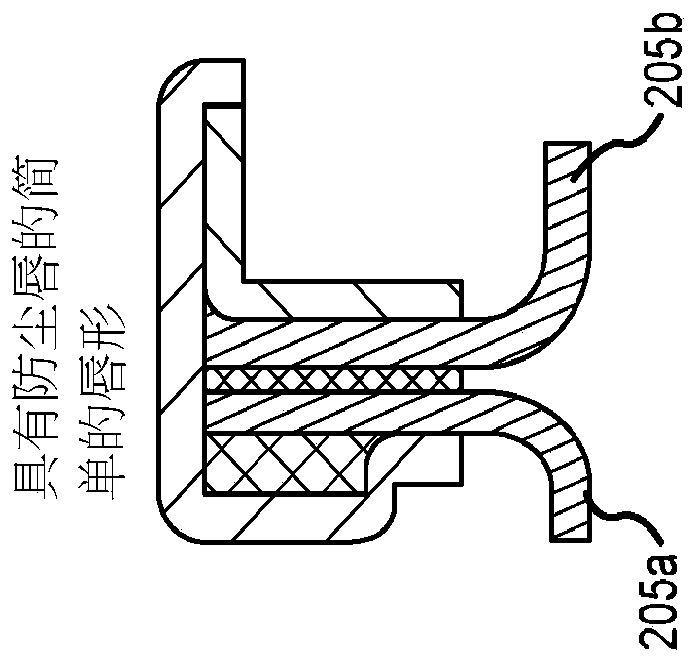

Embodiment Construction

[0024] In the following the examples are described more fully with reference to the accompanying drawings, of which the examples form a part, and in which are shown certain illustrative examples by way of illustration. These examples are disclosed in sufficient detail to enable those skilled in the art to practice the invention. Examples may, however, be implemented in many different forms and should not be construed as limited to the examples set forth herein. Therefore, the following detailed description should not be construed as limiting.

[0025] refer to Figure 4 , shows a multilayer radial lip seal 400 comprising a first layer 410 and a second layer 420 . Since lip seal 400 is configured such that first layer 410 contacts the surface to be sealed, first layer 410 may also be considered an outer layer of lip seal 400 . Since lip seal 400 is configured such that second layer 420 does not contact the surface to be sealed, second layer 420 may also be considered an inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com