Detachable totally-closed-shell vertical multilayer-plate-filter-element filter press

A multi-layer board and fully enclosed technology, applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of inconvenient instability, high risk of accidents, etc., and achieve easy adjustment of direction, reduction of dangerous accidents, wear resistance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

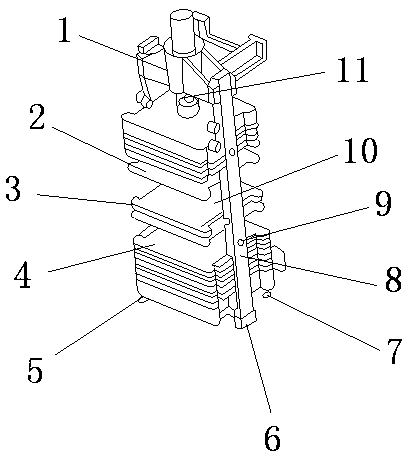

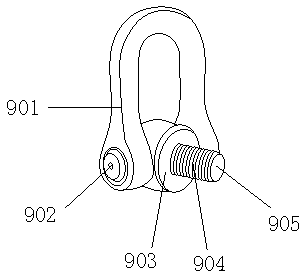

[0017] see Figure 1-Figure 2 , the present invention provides a detachable full-enclosed shell vertical multi-layer plate filter press: its structure includes a pressing device 1, filter cloth 2, filter frame 3, filter plate 4, filtrate 5, support plate 6, Suspension inlet 7, side plate 8, ring screw 9, filter residue layer 10, oil cylinder 11, the pressing device 1 is movably connected with the oil cylinder 11, the filter cloth 2 is arranged on the top of the filter frame 3, and the filter frame 3 Set on the top of the filter plate 4, the filtrate 5 is set under the filter plate 4, the support plate 6 is connected with the side plate 8, the side plate 8 is connected with the eye screw 9, the suspension inlet 7 Located on one side of the filtrat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap