Method for checking and calculating rolling force energy of high-speed hot-rolled wire

A calculation method and rolling force technology, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve problems such as the inability to meet the multi-stand rolling force and energy parameter verification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

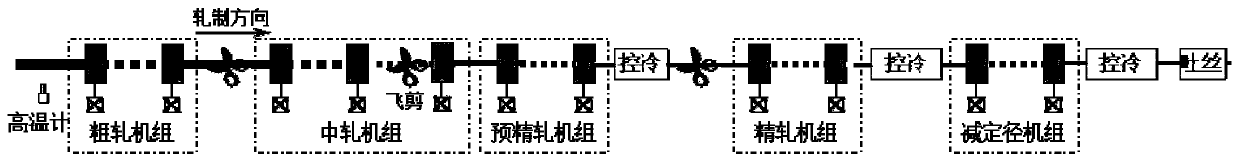

[0107] Take the production of Φ4.5mm hot-rolled smooth wire in a high-speed wire factory as an example for calculation. The plant has a total of 6 roughing mills, 6 intermediate rolling mills, 6 (5+1) pre-finishing mills, 10 (2+2+2+2+2) double-module rolling mills and 4 (1+1+2 ) minus sizing machine. The calculation process is shown in the following three tables, where the red numbers are known data. From the calculation results of rolling mill force and energy in Table 3, it can be seen that the rolling mill and motor power equipped in this factory can completely meet the production of Φ4.5mm hot-rolled smooth wire rod.

[0108]

[0109]

[0110]

[0111]

Embodiment 2

[0113] Further, take the production of Φ5.5mm hot-rolled smooth wire rod in this high-speed wire rod factory as an example for calculation. The calculation process is shown in the following three tables, where the red numbers are known data. From the calculation results of rolling mill force and energy in Table 3, it can be seen that the 32 rolling mills and motor power equipped in this factory can fully meet the production of Φ5.5mm hot-rolled smooth wire rod.

[0114]

[0115]

[0116]

[0117]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com