Special tool for spinning process of T-shaped deep stretching type plate belt wheel

A spinning process and drawing technology, which is used in the field of special tooling for the spinning process of T-shaped deep-drawing plate pulleys, which can solve the problem of unevenness, uneven groove shape, uneven web plane, upper and lower sides. and other problems, to achieve the effect of stable product quality, short processing time and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

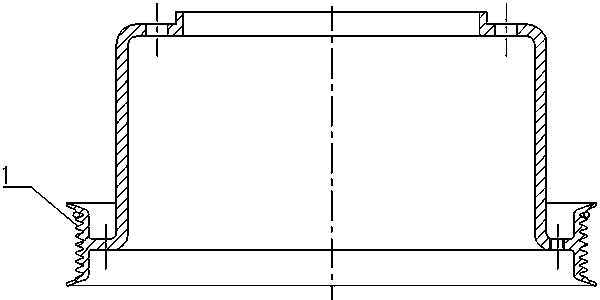

[0031] Such as figure 1 As shown, 1 is the groove shape to be processed, the product is a rotary part, 8-groove multi-ribbed crankshaft pulley, the height of the web plate corresponding to the groove shape is 90mm from the bottom plane, and the outer diameter is φ214mm.

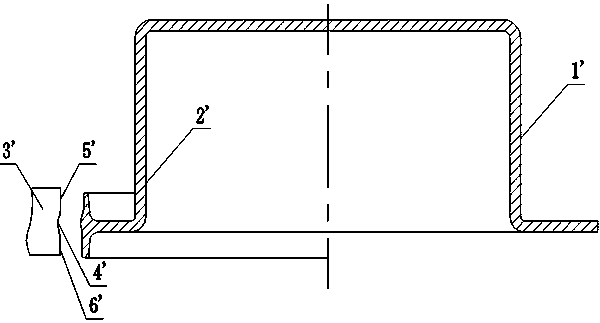

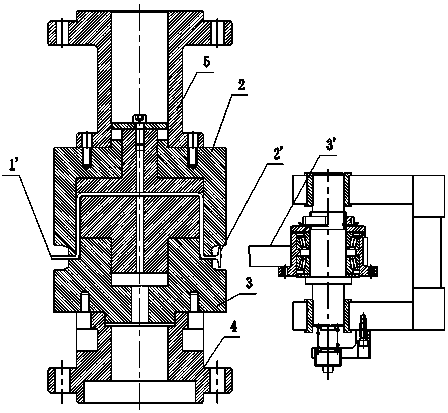

[0032] Such as figure 2 , image 3 As shown, the upper mandrel 2 and the lower mandrel 3 constitute the mandrel fixture, the upper mandrel 2 is connected with the upper connection plate 5 assembled on the upper spindle of the spinning equipment, and the lower mandrel 3 is connected with the lower mandrel 5 assembled on the lower spindle of the spinning equipment. The connection plate 4 is connected, and the first preformed rotary wheel 3' is correspondingly installed on the rotary wheel shaft; 1' is the shape of the sheet metal base material before spinning, which is installed in the mandrel fixture, and 2' is the spinning forming step ① forming The final shape, 3' is the first preforming roller, 4' is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com