A gravity unloading device for three-dimensional active movement of air bearing supports

A gravity unloading and three-dimensional technology, which is applied to the simulation device of space navigation conditions, transportation and packaging, space navigation equipment, etc., can solve the problem that microgravity simulation equipment is not suitable for large loads to be unloaded, and achieve high precision and fast response Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

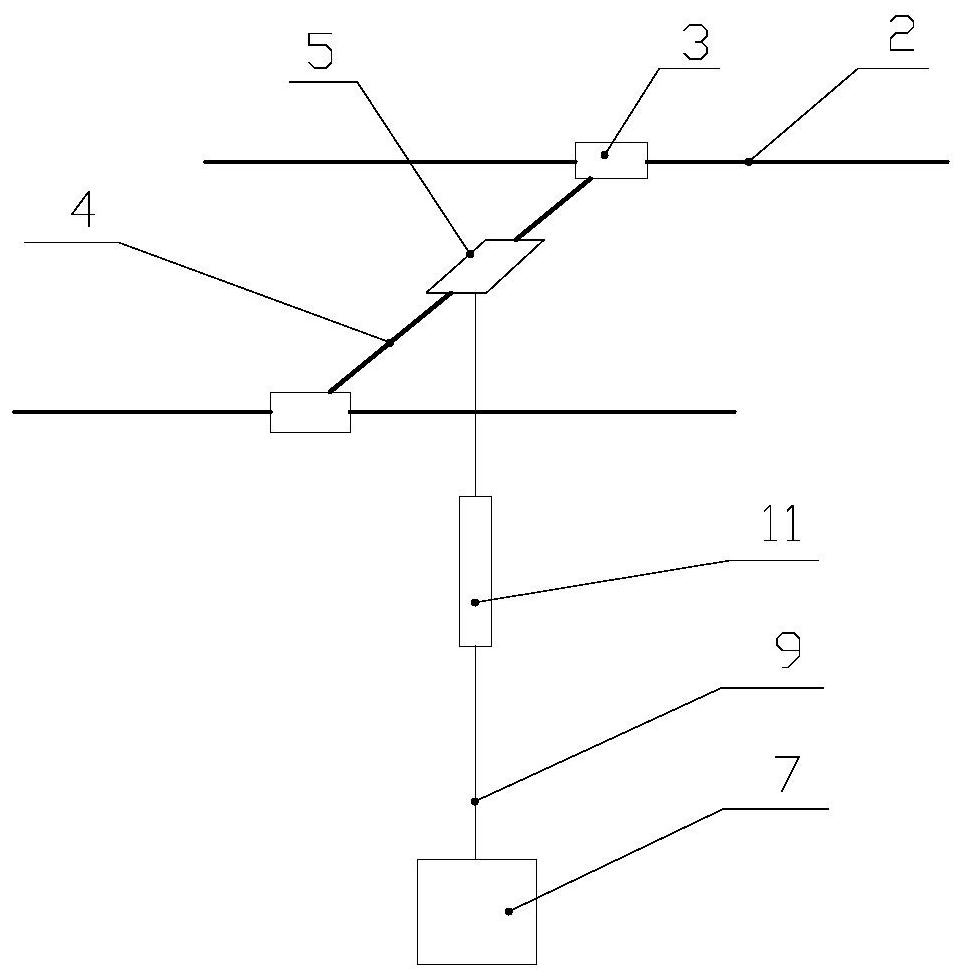

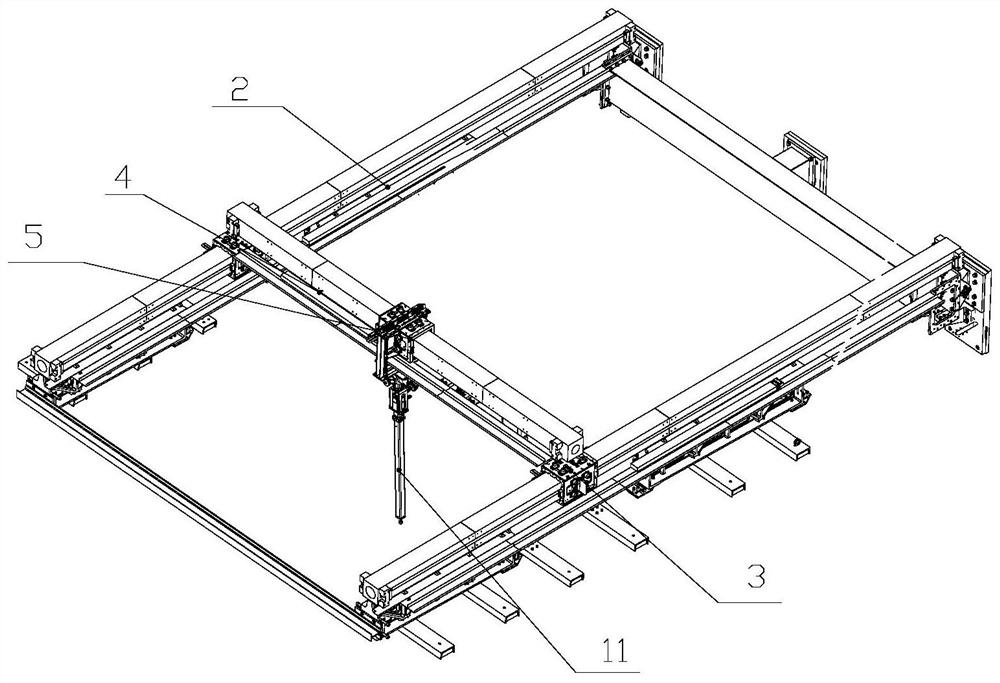

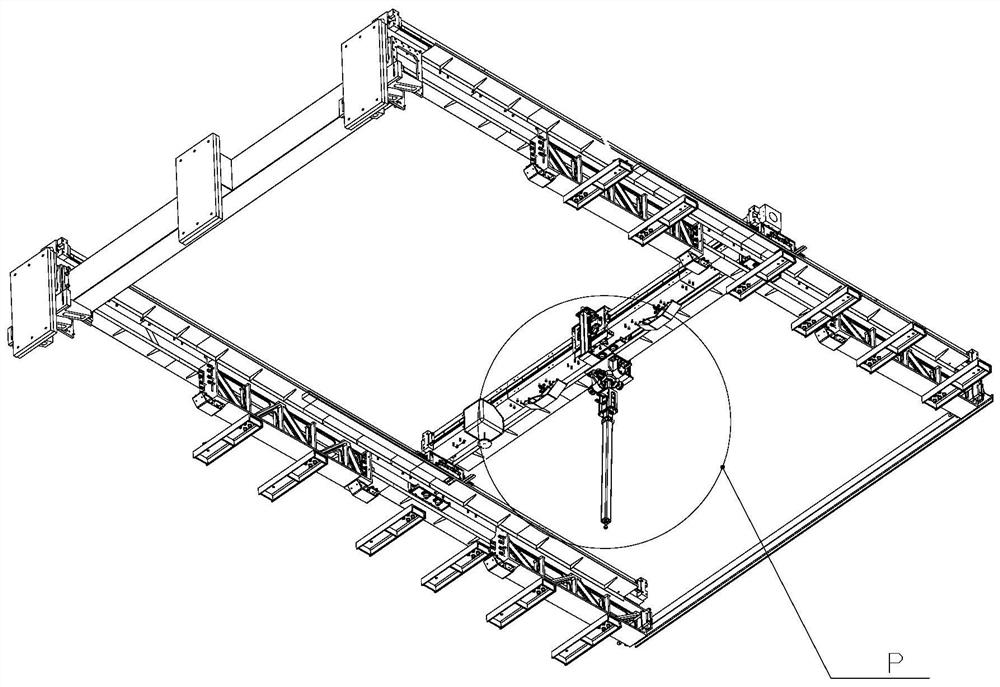

[0015] Specific implementation mode one: combine Figure 1~4 Describe this embodiment, a gravity unloading device for three-dimensional active movement of an air-floating support, which includes a load-bearing frame, two fixed air-floating guide rails 2 fixed on the top of the load-bearing frame in parallel in the horizontal direction, and one-to-one sliding installation on the top of the load-bearing frame. The first air-floating block 3 on the two fixed air-floating rails 2, the mobile air-floating rail 4 fixed between the two first air-floating blocks 3, the second air-floating rail 4 slidingly installed on the mobile air-floating rail 4 The floating block 5 and the electric cylinder type unloading mechanism 11 fixed on the second air floating block 5, wherein the movement of each air floating block on its corresponding air floating guide rail is realized by a linear motor, and the electric cylinder Type unloading mechanism 11 comprises connection frame 11-1, angle sensor 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com