Automatic chain plate cleaning device

An automatic cleaning and chain plate technology, which is applied in cleaning devices, transportation and packaging, cleaning methods and utensils, etc., can solve serious problems such as chain plate sticking, hole blocking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

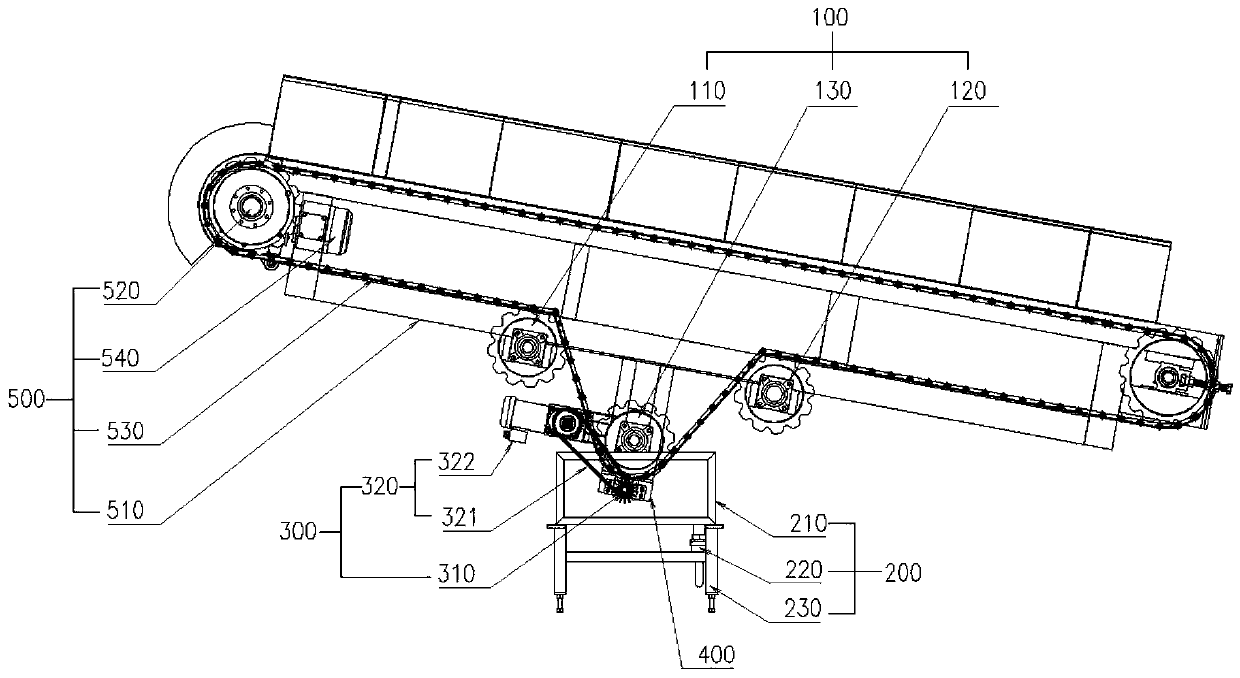

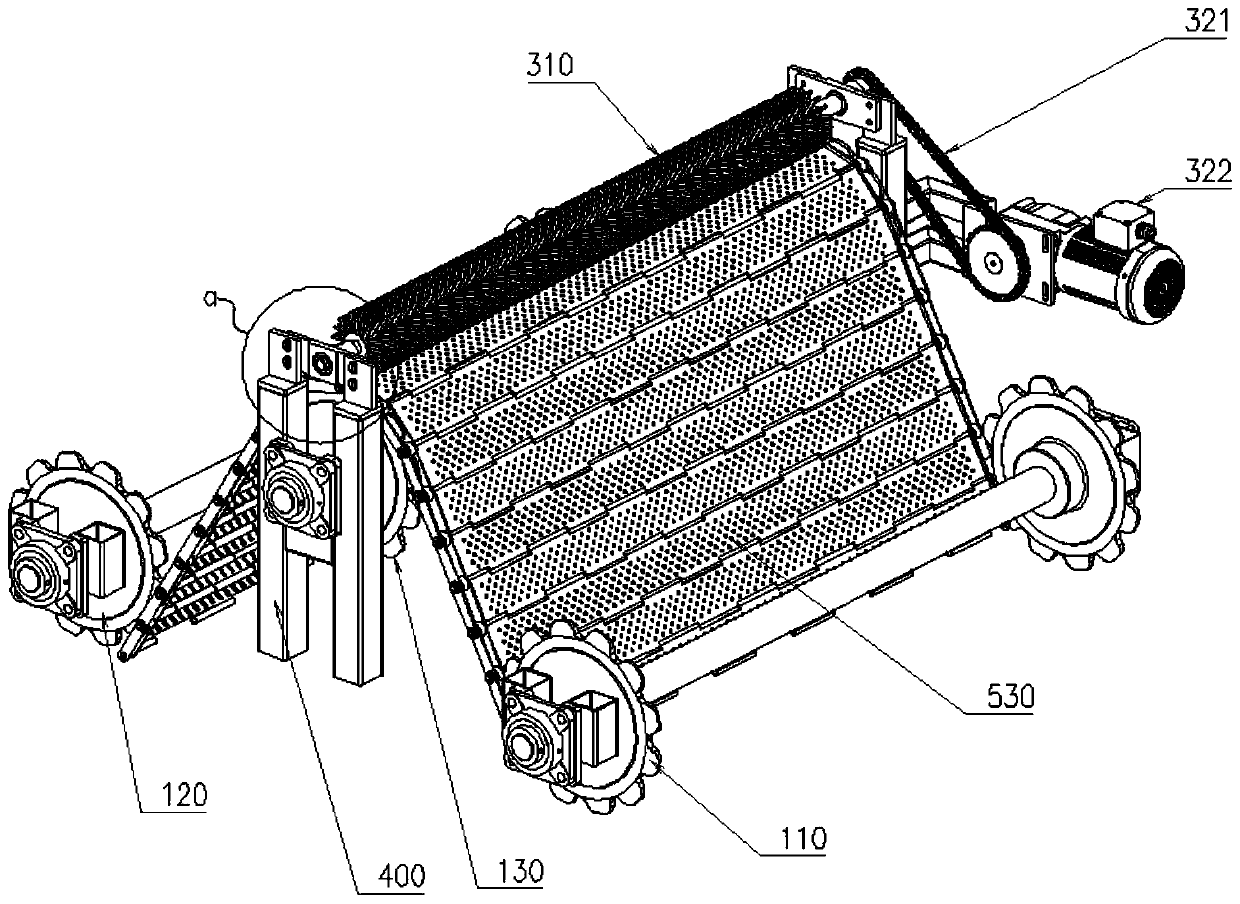

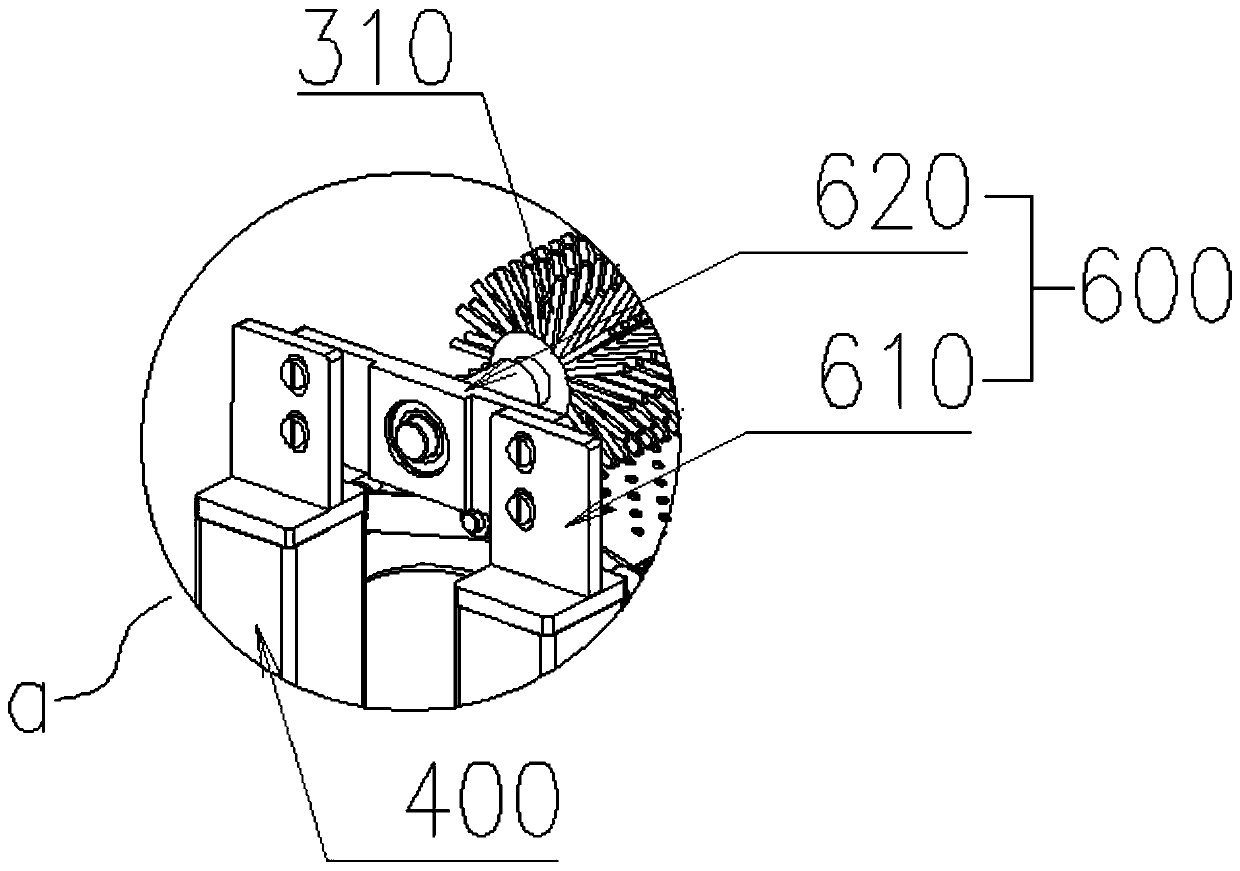

[0031] refer to Figure 1-4 As shown, a chain plate automatic cleaning device is installed below the parallel chain plate machine 500, which includes: a chain plate bias mechanism 100, a water tank assembly 200, a brush roller mechanism 300 and a fixing frame 400;

[0032] Wherein the parallel chain plate machine 500 is a conventional parallel chain plate machine, which includes a parallel chain plate frame body 510, a sprocket wheel 520 rotatably connected to both sides of the parallel chain plate frame body 510, and a parallel chain wheel wound between the sprocket wheels 520 on both sides. The chain plate 530 of the chain plate machine and the reduction motor 540 for driving the rotation of the sprocket 520; when the parallel chain plate machine 500 starts, the reduction motor 540 drives the chain plate 530 of the parallel chain plate machine through the sprocket 520 for transmission.

[0033] The fixed frame 400 has two groups symmetrically fixed on the front and rear side...

Embodiment 2

[0046] It is basically the same as Embodiment 1, except that the driving mechanism 320 includes a sprocket coaxially fixedly installed on the end of the same side of the third sprocket set 130 and the brush roller assembly 310 and a chain installed between the two sets of sprockets (not shown in the figure); that is, the third group of sprockets 130 provides rotational power to the brush roller assembly 310 through chain transmission.

Embodiment 3

[0048] It is basically the same as Embodiment 1, except that the driving mechanism 320 includes a pulley coaxially fixedly installed on the end of the same side of the third sprocket set 130 and the brush roller assembly 310 and a belt installed between the two sets of pulleys (Fig. not shown in); that is, the third group of sprockets 130 provides rotational power to the brush roller assembly 310 through belt transmission.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com