Bottle applique soaking device

A technology of soaking box and material frame, applied in the directions of transportation and packaging, separation of objects, separation of piles, etc., can solve the problems of cumbersome operation, affecting the adhesion effect of decals and bottle bodies, and low decal efficiency, and achieve the effect of improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

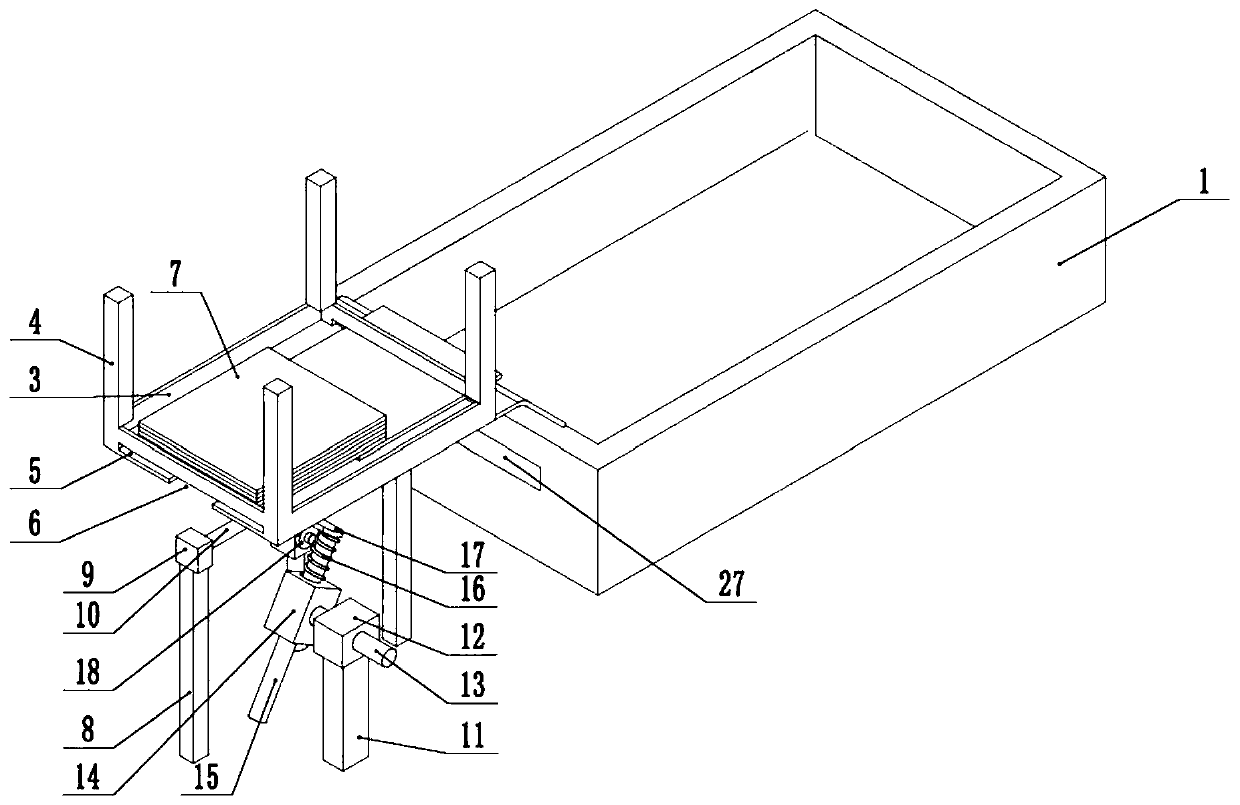

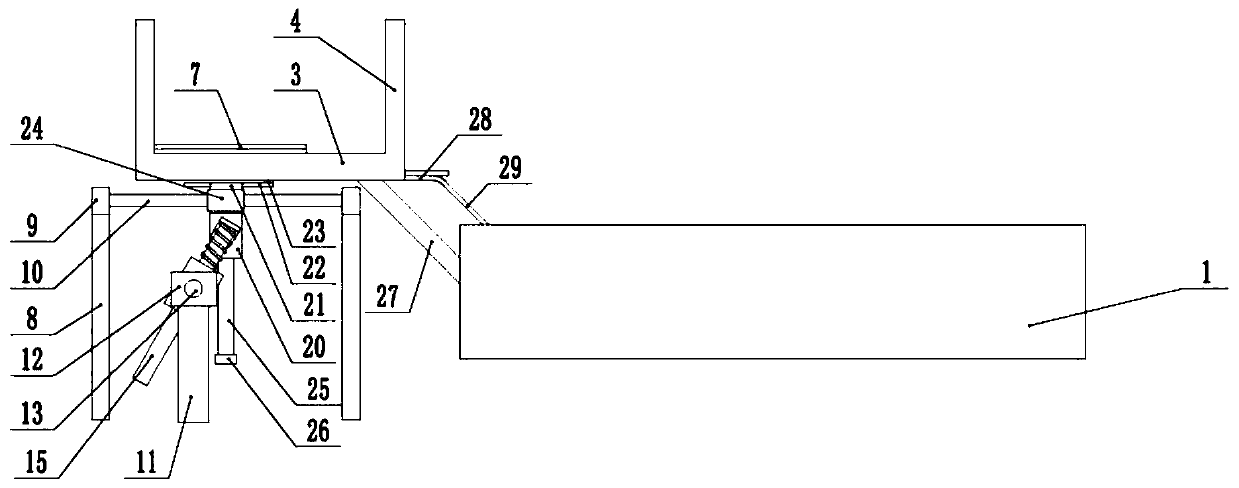

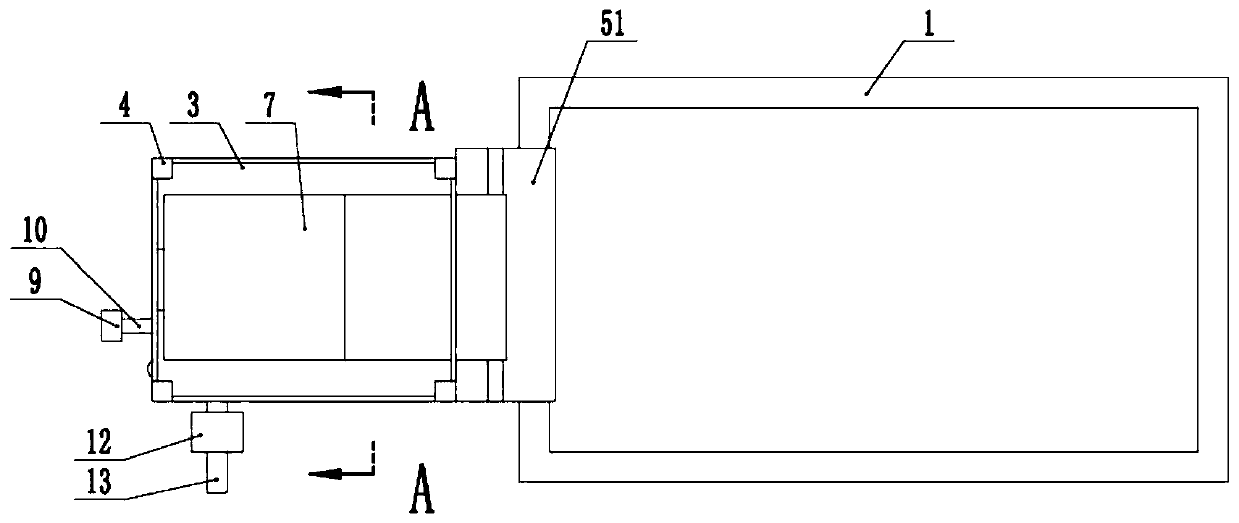

[0039] The embodiment is basically as attached figure 1 and figure 2 Shown: a bottle decal soaking device, including a soaking box 1, a feeding unit is provided on one side of the soaking box 1, and the feeding unit in this embodiment includes a retrieving frame 3 for placing cardboard 7, a retrieving frame 3 It is in a cuboid structure, and the inside of the retrieving frame 3 is hollow, and the top of the retrieving frame 3 is an open end. The top of the retrieving frame 3 is provided with four limit frames 4 , the four limit frames 4 are rectangular rod-shaped structures, and the four limit frames 4 are respectively located at four right angles of the retrieving frame 3 .

[0040] like figure 2 As shown, the right side of the retrieving frame 3 is connected with a material guide plate, and the material guide plate includes a connecting plate 28 and a slide plate 29. The connecting plate 28 in this embodiment is positioned at the bottom of the retrieving frame 3 and is w...

Embodiment 2

[0055] like Figure 5 and Figure 6 As shown, a bottle body decal soaking device differs from Embodiment 1 in that: a pick-up plate 30 and a material-receiving plate 31 are arranged in the soaking box 1, the material-receiving plate 31 is close to the feeding unit, and one end of the material-receiving plate 31 It is hinged with the soaking box 1, and a torsion spring is arranged between the receiving plate 31 and the soaking box 1 in this embodiment. The material receiving plate 31 is located above the material receiving plate 30 , the material receiving plate 30 can slide towards the material receiving plate 31 , and the material receiving plate 30 can slide vertically along the soaking tank 1 .

[0056] In this embodiment, both sides of the soaking tank 1 are provided with a horizontal chute 35 and a vertical chute 36, the vertical chute 36 and the horizontal chute 35 are vertically arranged, and the vertical chute 36 and the horizontal chute 35 are connected to each other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com