A kind of preparation method of 3,3,3-trifluoropropionic acid

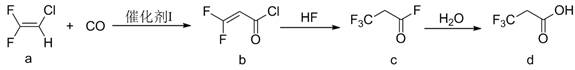

A technology of trifluoropropionic acid and trifluoropropionyl, which is applied in the field of preparation of 3,3,3-trifluoropropionic acid, can solve the problems of expensive raw materials and reagents, low yield and the like, and achieves improved conversion rate and selectivity, The effect of high conversion and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment includes the following steps:

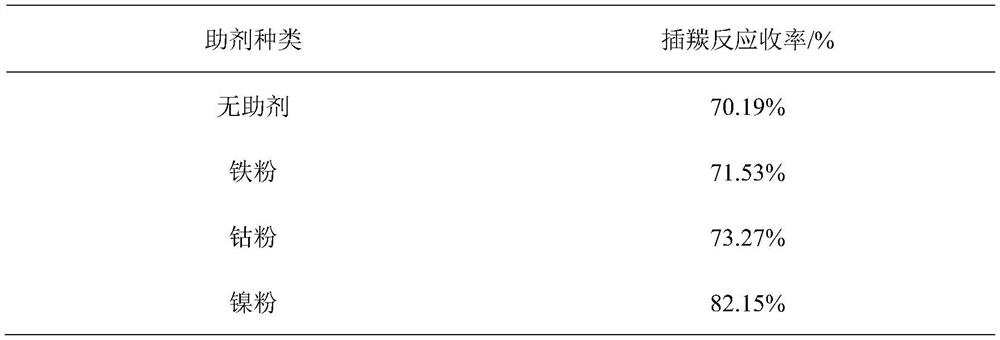

[0037] (1) add 4.5g (25.4mmol) palladium chloride, 1.5g (25.6mmol) nickel powder and 13.3g (50.8mmol) triphenylphosphine in 2L stainless steel reactor, vacuumize, suck in 1000mL anhydrous tetrahydrofuran, Under stirring, feed 250g (2.54mol) of 2-chloro-1-1-difluoroethylene, be warming up to 80°C, feed carbon monoxide to a pressure of 0.8MPa, and continue to feed carbon monoxide to a pressure of 0.8MPa after the insulation reaction until the pressure no longer decreases. , pass three times, pass time 5 hours, stop the reaction. Cool to room temperature, filter and recover divalent palladium and nickel powder, rapidly distill the filtrate at atmospheric pressure to obtain a mixed solution of organic solvent and product, then rectify and recover the organic solvent, and collect fractions at 70 to 72 °C, which is 3,3-difluoro- 2-Acryloyl chloride, weight 263.8 g, yield 82.15%.

[0038] (2) vacuumize the 2L Monel reaction ket...

Embodiment 2

[0041] This embodiment includes the following steps:

[0042](1): add 6.3g palladium acetate (28.1mmol), 1.7g nickel powder (29.0mmol) and 14.6g triphenylphosphine (55.6mmol) in 2L stainless steel reactor, vacuumize, suck in 1000mL anhydrous tetrahydrofuran, Under stirring, feed 275g (2.79mol) of 2-chloro-1-1-difluoroethylene, be warming up to 90°C, feed carbon monoxide to a pressure of 0.8MPa, and continue to feed carbon monoxide to a pressure of 0.8MPa after the insulation reaction until the pressure no longer decreases. , pass three times, pass time 5 hours, stop the reaction. Cool to room temperature, filter and recover divalent palladium and nickel powder, rapidly distill the filtrate at atmospheric pressure to obtain a mixed solution of organic solvent and product, then rectify and recover the organic solvent, and collect fractions at 70 to 72 °C to obtain 3,3-difluoro2- Acryloyl chloride, weight 281.9 g, yield 79.8%.

[0043] (2): evacuating the 2L Monel reactor, pump...

Embodiment 3

[0046] This embodiment includes the following steps:

[0047] (1) 2.5g (14.1mmol) of palladium chloride, 1.7g (29.0mmol) of nickel powder and 15.3g (58.3mmol) of triphenylphosphine were added to the 2L stainless steel reactor, evacuated, and 1240mL of anhydrous tetrahydrofuran was sucked in, Under stirring, feed 275g (2.79mol) of 2-chloro-1-1-difluoroethylene, be warming up to 80°C, feed carbon monoxide to a pressure of 0.8MPa, and continue to feed carbon monoxide to a pressure of 0.8MPa after the insulation reaction until the pressure no longer decreases. , pass three times, pass time 6 hours, stop the reaction. Cool down to room temperature, filter and recover divalent palladium and nickel powder, rapidly distill the filtrate at atmospheric pressure to obtain a mixed solution of organic solvent and product, then rectify and recover the organic solvent, and collect 70-72 °C fraction, which is 3,3-difluoro2 -Acryloyl chloride, weight 278g, yield 78.7%.

[0048] (2) vacuumize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com