Shuttle applicable to barrel-like braided fabric making equipment

A technology for manufacturing equipment and woven fabrics, applied in textiles, papermaking, textiles, looms, etc., can solve the problems of shuttles falling off, inability to process, and size limitations of shuttles, and achieve the effect of efficient weaving, ensuring stability, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means and effects realized by the present invention easy to understand, the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

[0015]

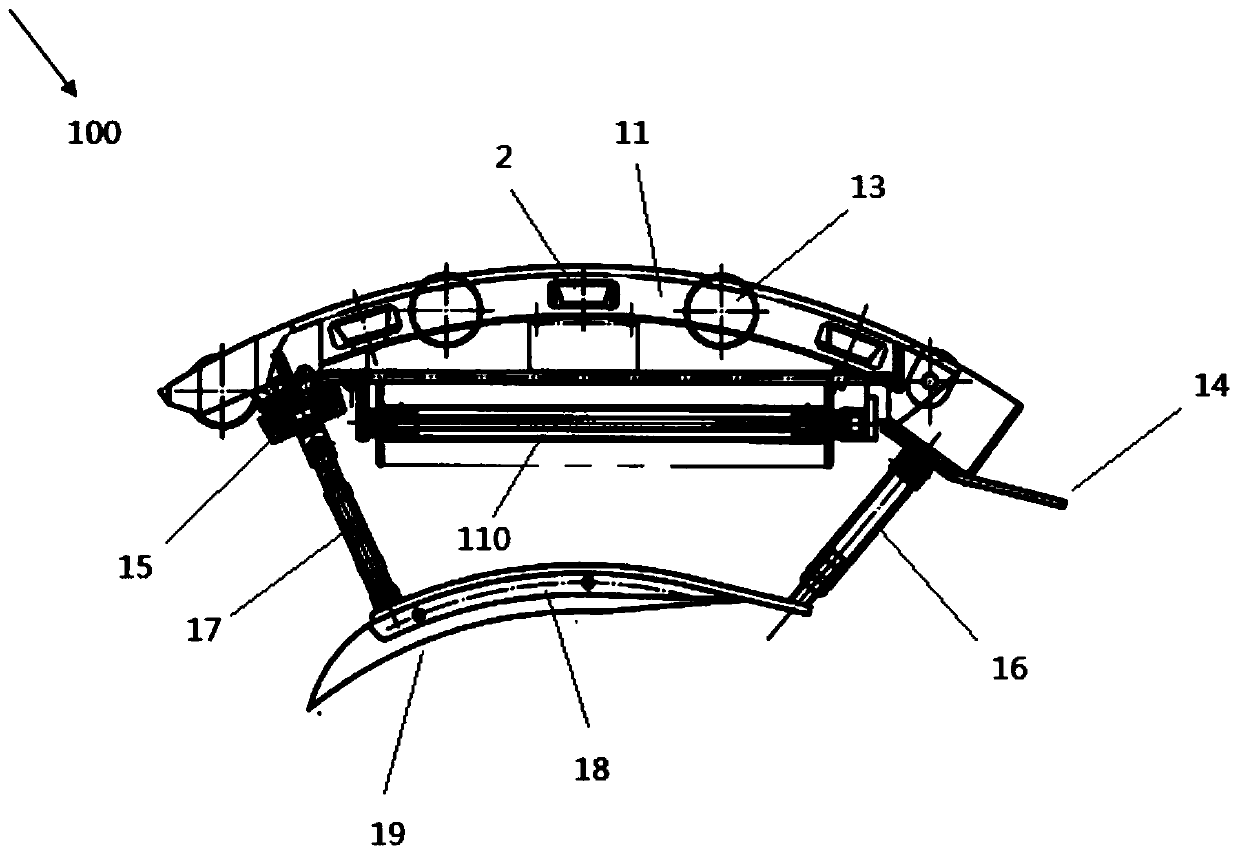

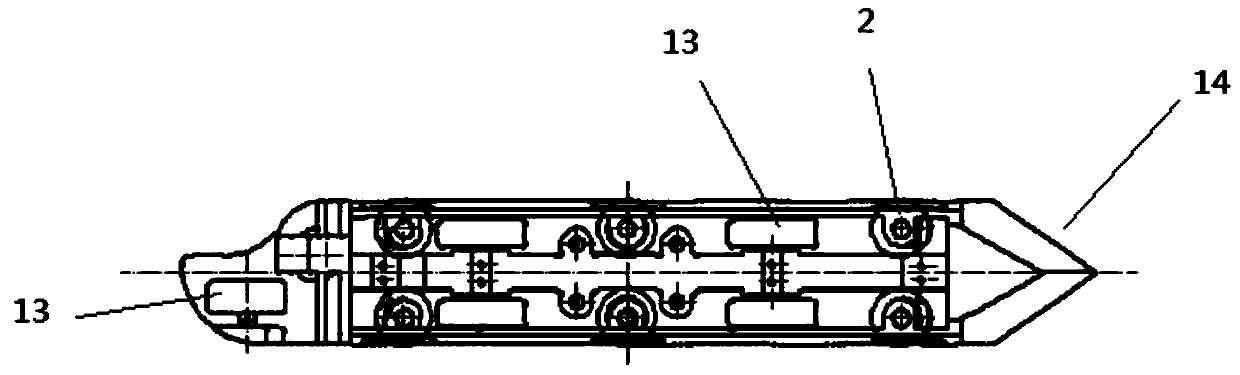

[0016] The shuttle 100 applicable to the cylindrical knitted fabric manufacturing equipment of this embodiment is installed in the guide groove with an inclined surface of the cylindrical knitted fabric manufacturing equipment, and is used to load and introduce the weft thread to complete the weaving process. It has a shuttle body 1 and a plurality of shuttle wheel 2.

[0017] In this embodiment, the tubular braid manufacturing equipment includes an annular frame body, a braid guide cylinder, a rotary part, a driving part, and a support part. To divide the warp, the shuttle 100 is accommodated in the annular frame, follows the rotary part to rotate around the braid guide cylinder, and shuttles through the divided warp thread to weave the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com