Volume expanding method for seepage-proofing type wet-discharging tailings pond

A technology of tailings pond and wet discharge, which is applied in the expansion of mine tailings pond and non-coal mine field, can solve the problem that the anti-seepage type wet discharge tailings pond cannot be effectively expanded, so as to save storage capacity and investment, extend the service life, increase The effect of storage capacity

Pending Publication Date: 2020-04-21

CHINA NERIN ENG

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] In order to solve the above-mentioned technical problems, the purpose of the present invention is to provide a method for expanding the capacity of the anti-seepage wet discharge tailings pond that has been in service to the end, by using the newly added clarification pool as the tailings pond that has been in service to the end The water storage tank, so that the anti-stacking "wearing a hat" expansion can be carried out in the tailings pond, which solves the problem that the anti-seepage type wet tailings pond cannot be effectively expanded in the end

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

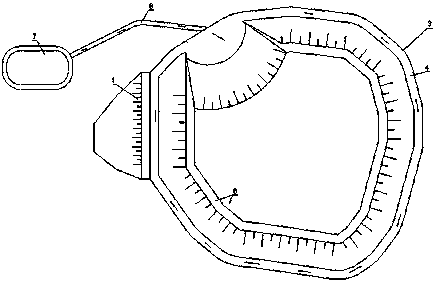

[0026] The final effective storage capacity of the original design of a tailings pond is about 6400×10 4 m 3 , the top area of the tailings pond is about 270×10 4 m 3 , through the implementation of the above-mentioned tailings wet drainage stacking dam scheme, the height is increased by about 15m, and the new storage capacity of about 2800×10 is obtained directly on the original storage 4 m 3 , creating huge benefits for the enterprise.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

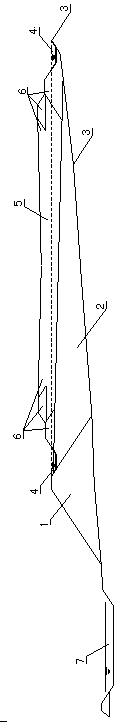

The invention discloses a volume expanding method for a seepage-proofing type wet-discharging tailings pond. On the premise of basically not adding land, a dam body and a horizontal seepage-proofing system of an existing tailings pond utilize a newly built clear water tank or an adjacent clear water tank in a newly built tailings pond as a water storage tank for draining away water and draining off floodwaters while the tailings pond which serves to the terminal stage is reversely stacked and heightened to expand volume; under the conditions of adding an overflow channel, a water drainage openchannel and the clear water tank, stacking and damping can be realized by ore drawing, so that reservoir volume can be greatly increased, especially great reservoir volume is obtained during volume expanding for some large-area tailings ponds, and therefore, service length, for a mine, of the tailings pond is prolonged, reservoir volume and investment of the newly built tailings pond are saved, great benefits are created for the mine enterprises, and land also can be saved.

Description

technical field [0001] The invention relates to the field of non-coal mines, in particular to the field of expansion of mine tailings storage, in particular to a method for expanding the capacity of an anti-seepage wet discharge tailings storage in the field of non-coal mines. Background technique [0002] Tailings pool refers to the place where dams are built to intercept valley mouths or enclosures, and are used to stockpile metal or non-metal mines for ore sorting and then discharge tailings or other industrial waste. With the country's emphasis on environmental protection in recent years, the promulgation of the "Law of the People's Republic of China on the Prevention and Control of Environmental Pollution by Solid Waste" and the implementation of the "Standards for Pollution Control of General Industrial Solid Waste Storage and Disposal Sites" have prompted many tailpipes that have reached Class II standards. When the ore is stockpiled, it needs to carry out anti-seepag...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E02D17/18E03F5/10E03F3/04

CPCE02D17/18E03F3/046E03F5/10

Inventor 刘瀚和金志斌卢建京袁永强

Owner CHINA NERIN ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com