Garbage vertical discharge device for building high-rise

A discharge device and garbage technology, which is applied in the direction of buildings, building components, building structures, etc., can solve the problems of pipeline impact damage, large impact force, large construction waste and dust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

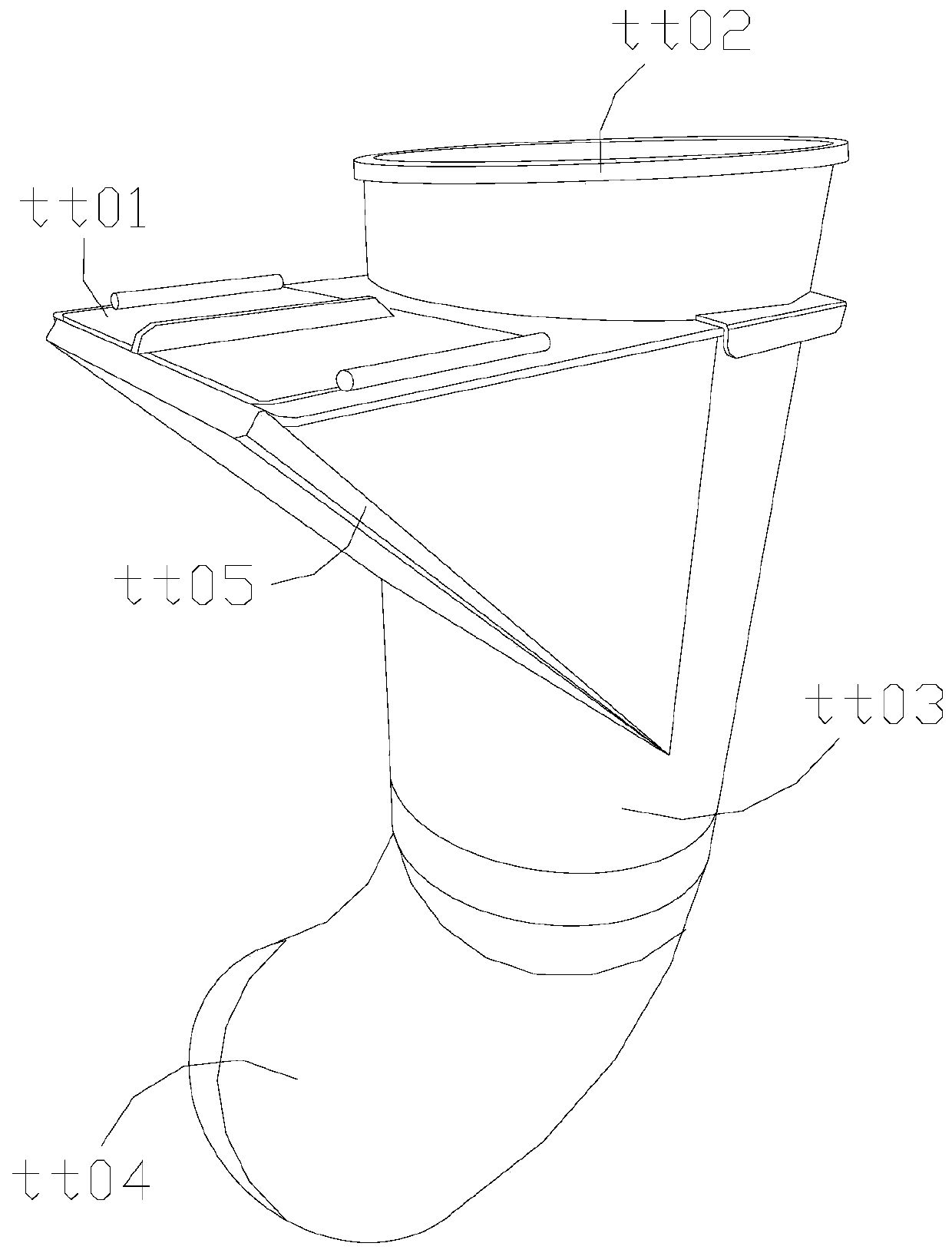

[0032] as attached figure 1 to attach Figure 5 Shown:

[0033] The invention provides a vertical discharge device for building high-rise garbage, the structure of which includes an insertion inlet tt01, an upper connection guide outlet tt02, a middle pipe tt03, an arc relief outlet tt04, and an auxiliary inlet tt05.

[0034] The insertion port tt01 and the auxiliary port tt05 are integrated structures, the upper connection guide port tt02 is welded above the middle tube tt03, and the end of the middle tube tt03 away from the upper connection guide port tt02 is connected to the arc buffer port tt04.

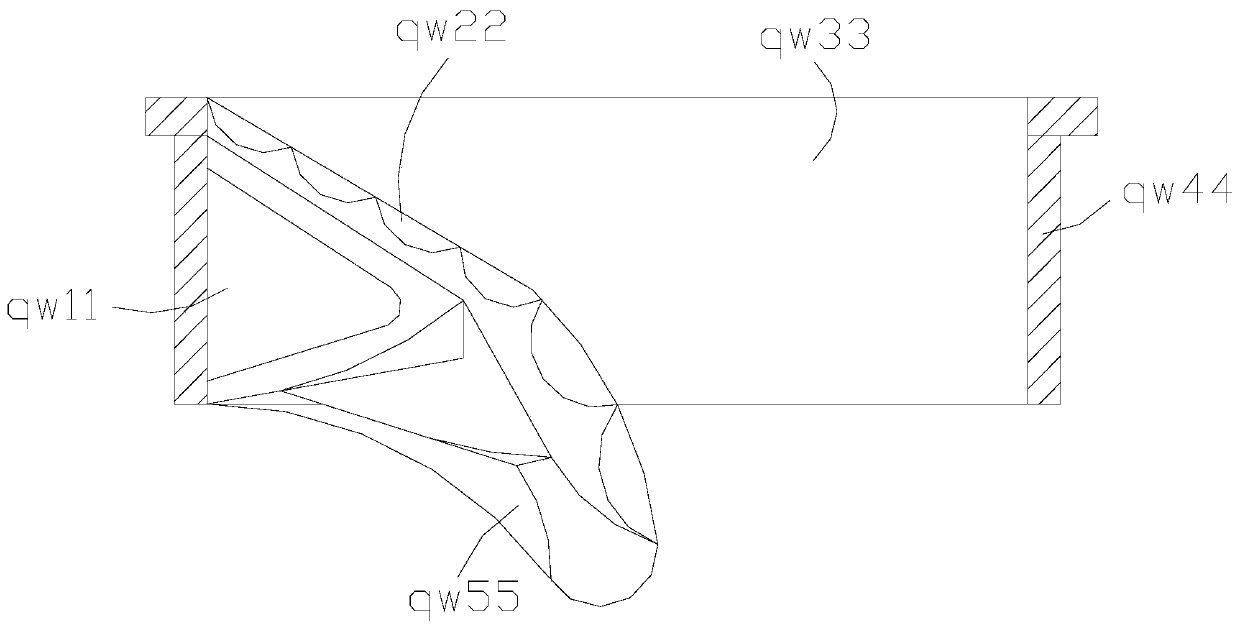

[0035] Wherein, the upper connection guide port tt02 includes a stabilizing force angle qw11, a large surface arc qw22, a central tube qw33, an outer limiting shell qw44, and a swing core qw55, and the stabilizing force angle qw11 is against the outer surface of the large surface arc qw22. The large surface arc qw22 is connected with the swing core qw55, the middle tube qw33 is...

Embodiment 2

[0042] as attached Figure 6 to attach Figure 8 Shown:

[0043] Wherein, the arc buffer port tt04 includes a middle buffer tube hh1, an outer layer hh2, a core impact angle hh3, and a force isolation angle hh4. The center buffer tube hh1 is installed inside the outer layer hh2, and the force isolation angle hh4 conflicts with On the outer surface of the core attack angle hh3, the force isolation angle hh4 is distributed at intervals with the connecting parts, the core attack angle hh3 is evenly distributed in an arc shape, the outer support layer hh2 controls the range of the inner road, and the force isolation angle hh4 allows The connecting parts have a certain resistance to the fixed interval force, the core impact angle hh3 bears the external impact, gathers it to press inward, and the middle buffer tube hh1 allows the object to move smoothly.

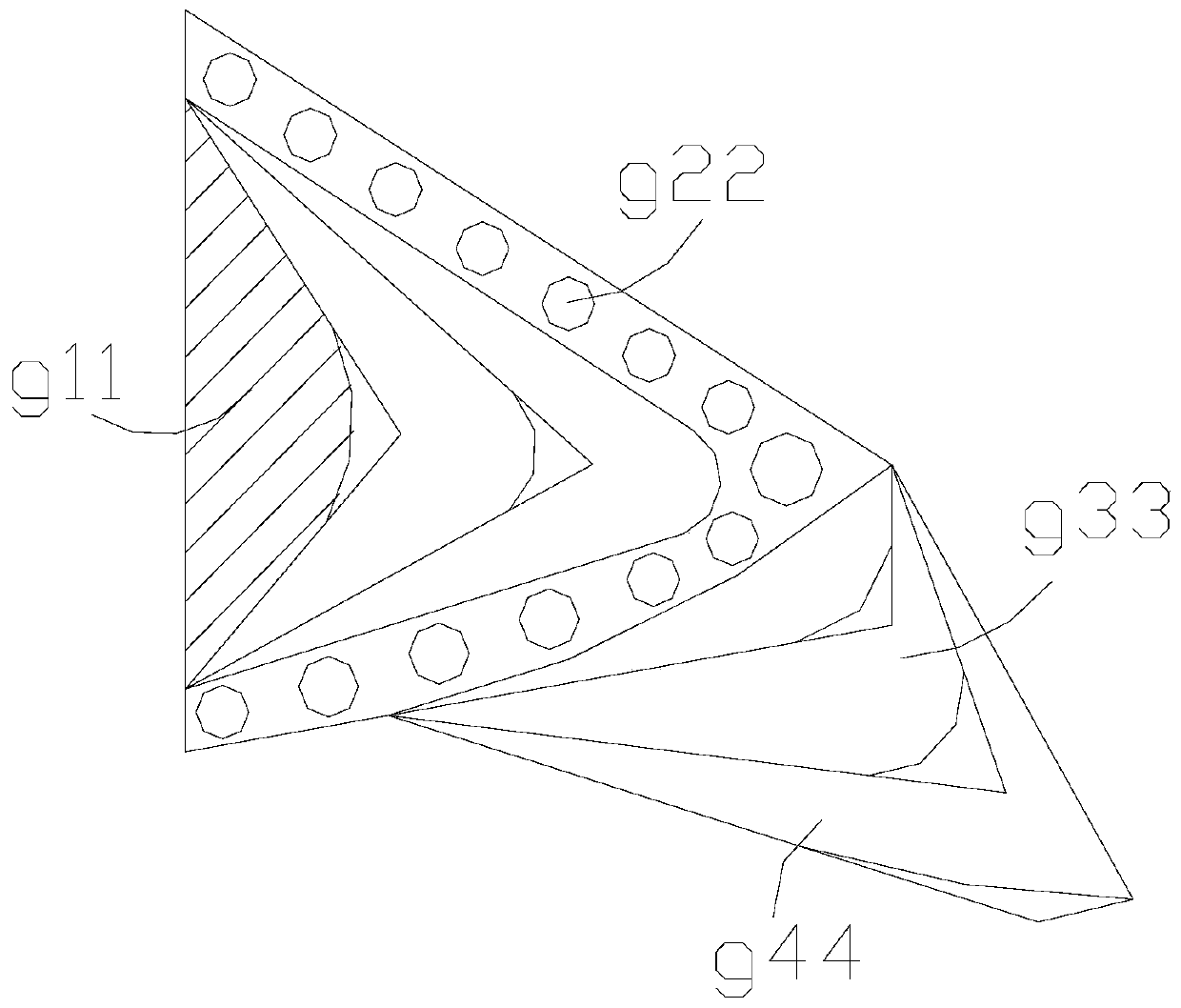

[0044] Wherein, the core punching angle hh3 includes the punching surface tr11, the middle support bar tr22, the punching angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com