Construction method for fabricating composite waterproof curtain by embedding rigid piles into low-strength concrete piles

A technology of concrete piles and water-stop curtains, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as high construction costs, waste of resources, and environmental pollution, and achieve material cost reduction, resource conservation, and natural resource conservation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

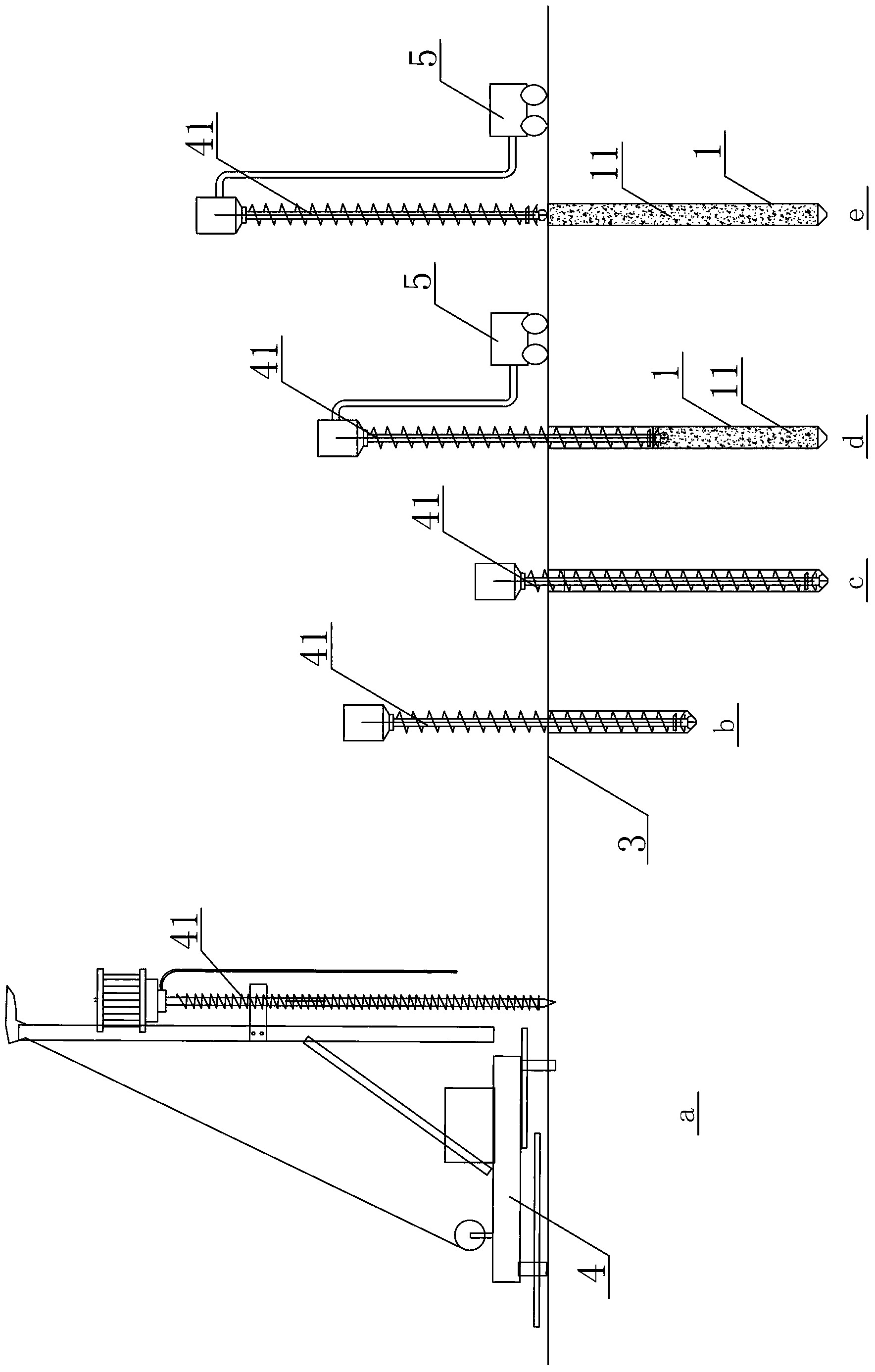

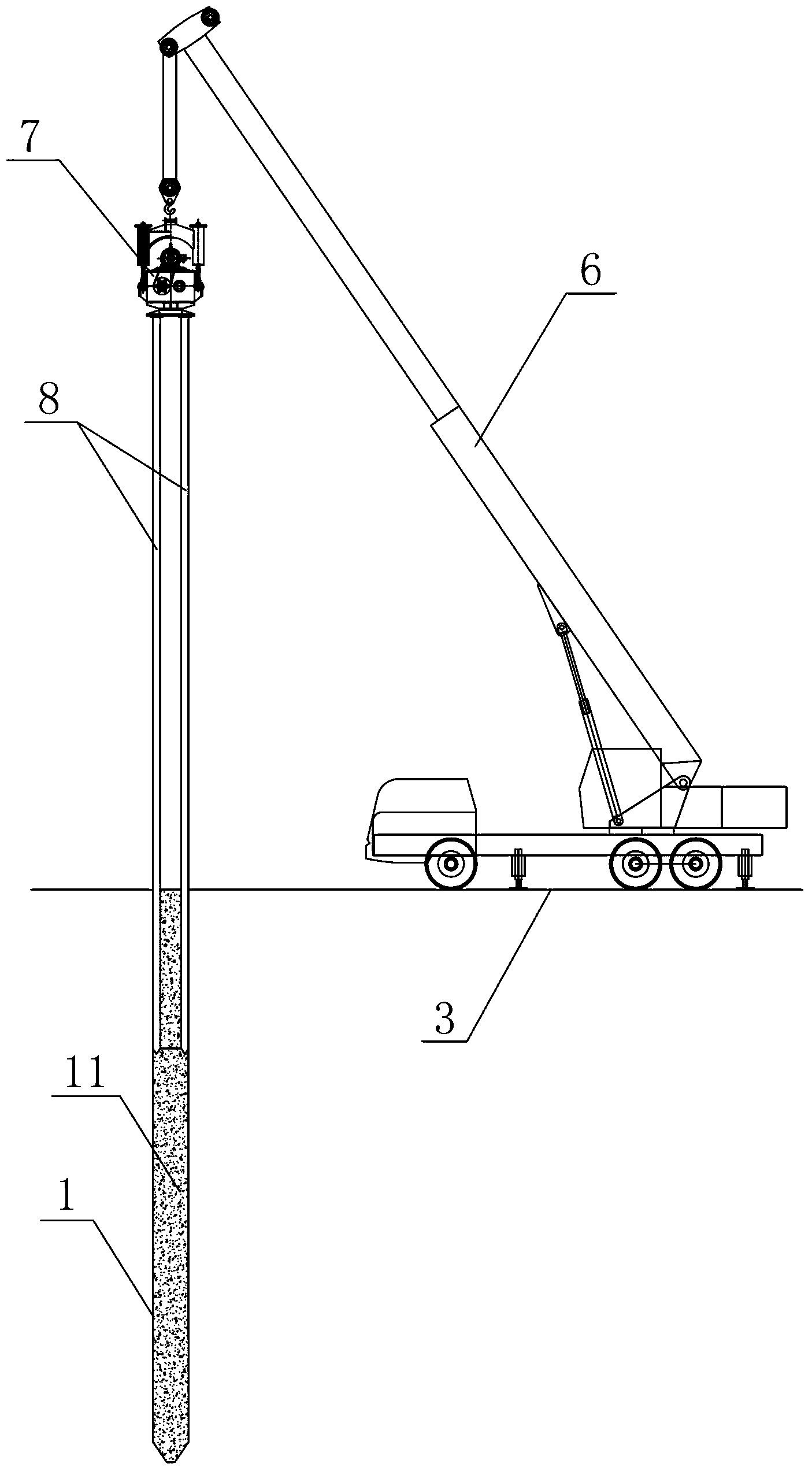

[0060] refer to Figure 1 to Figure 12 , the overall implementation method of the present invention is:

[0061] Measurement and setting out --- use long screw pile machine to drill low-strength concrete pile holes --- long screw pile machine pumps low-strength concrete while lifting the auger drill until the design pile bottom elevation is reached --- in low-strength concrete piles Implant the reserved groove forming rod in the middle---low-strength concrete pile into pile---pull out the reserved groove forming rod to form the reserved groove---drill the rigid pile hole---clean the reserved groove--- Hanging the reinforcement cage---injecting the rigid pile---maintenance.

[0062] The construction process of the present invention is specifically described below in conjunction with the accompanying drawings:

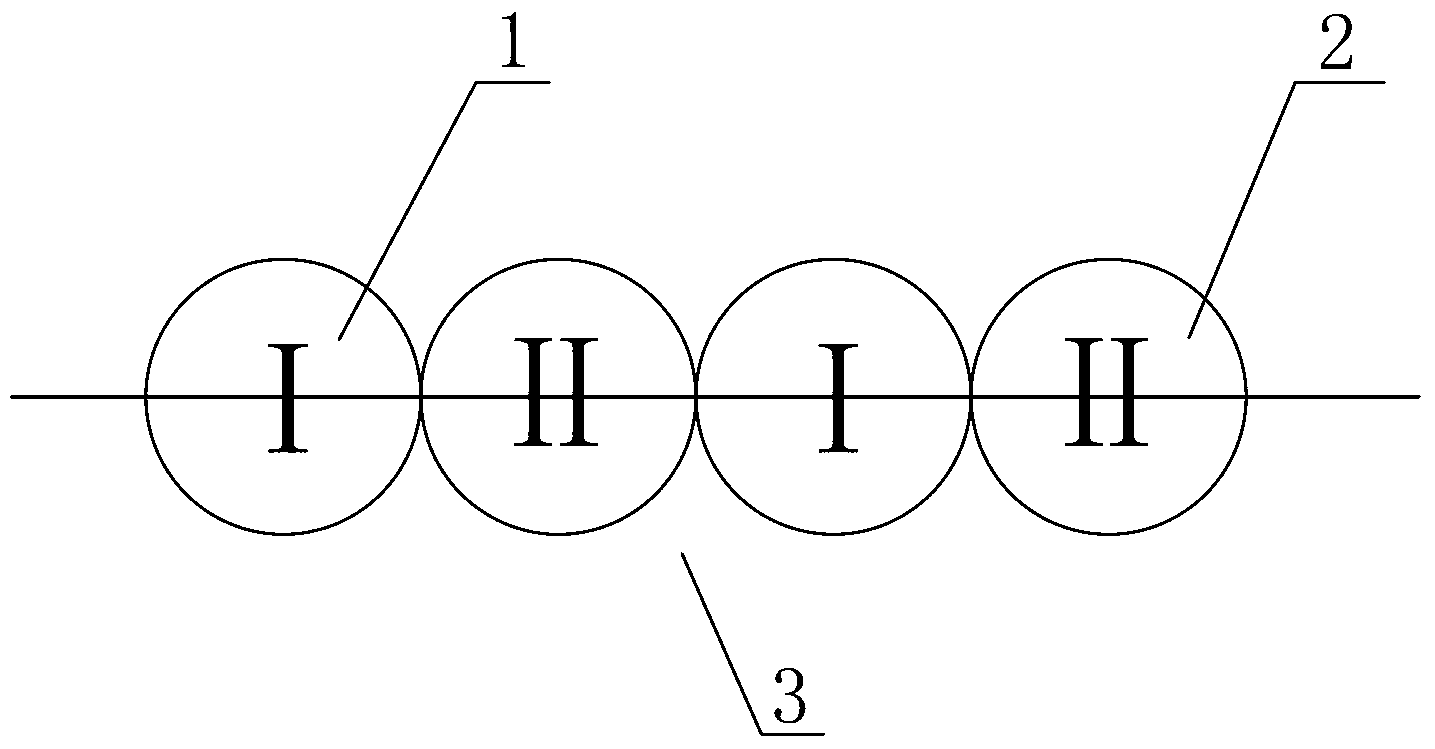

[0063] refer to figure 1 , mark the low-strength concrete pile 1 and the rigid pile 2 on the ground 3 in turn according to the design position at the site design posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com