Airborne laser radar beam pointing calibration method and system and laser spot detector

An airborne laser radar and laser spot technology, which is applied in the field of beam pointing calibration of airborne laser radar, can solve the problems that attitude measurement accuracy affects the beam pointing calibration results, high cost, and it is difficult to identify and determine the laser spot in ground calibration. Achieve the effect of improving the target measurement accuracy and realizing precise calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following describes the implementation process of the technical solution of the present invention in conjunction with specific embodiments, and is not intended to limit the present invention.

[0047] The invention is used to accurately calibrate the beam direction of the laser radar three-dimensional spatial information collection in the fields of surveying and mapping, transportation and the like, and can improve the accuracy of acquiring the spatial information.

[0048] An airborne lidar beam pointing calibration method of the present invention is specifically implemented as follows:

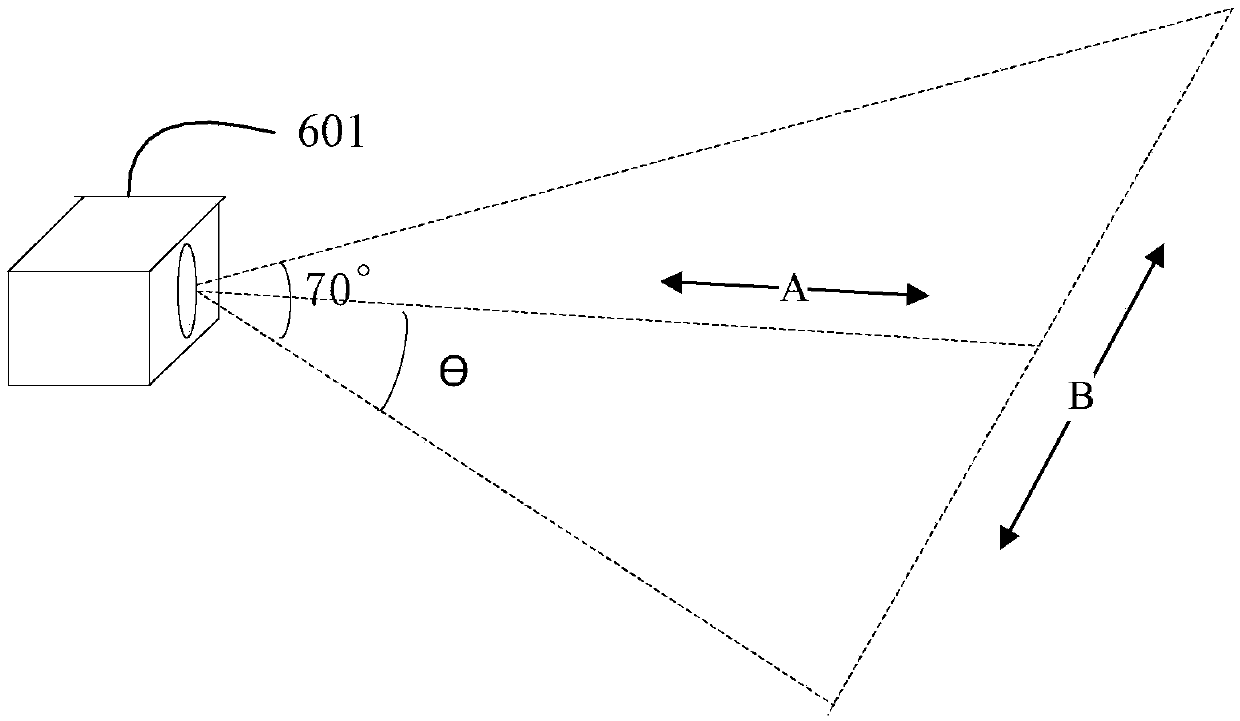

[0049] Combine figure 1 , A schematic diagram of the calibration field of an airborne laser radar beam pointing calibration method of the present invention, the calibration field is an indoor or outdoor fixed place, the ground of the calibration field is flat or has little undulation, the lidar is set in the calibration field, and the laser There is no obstruction within the range θ of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com