Pole piece and isolating film synchronous traction attaching device

A technology of laminating device and isolation film, which is applied in the direction of cleaning device, transportation and packaging, conveyor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

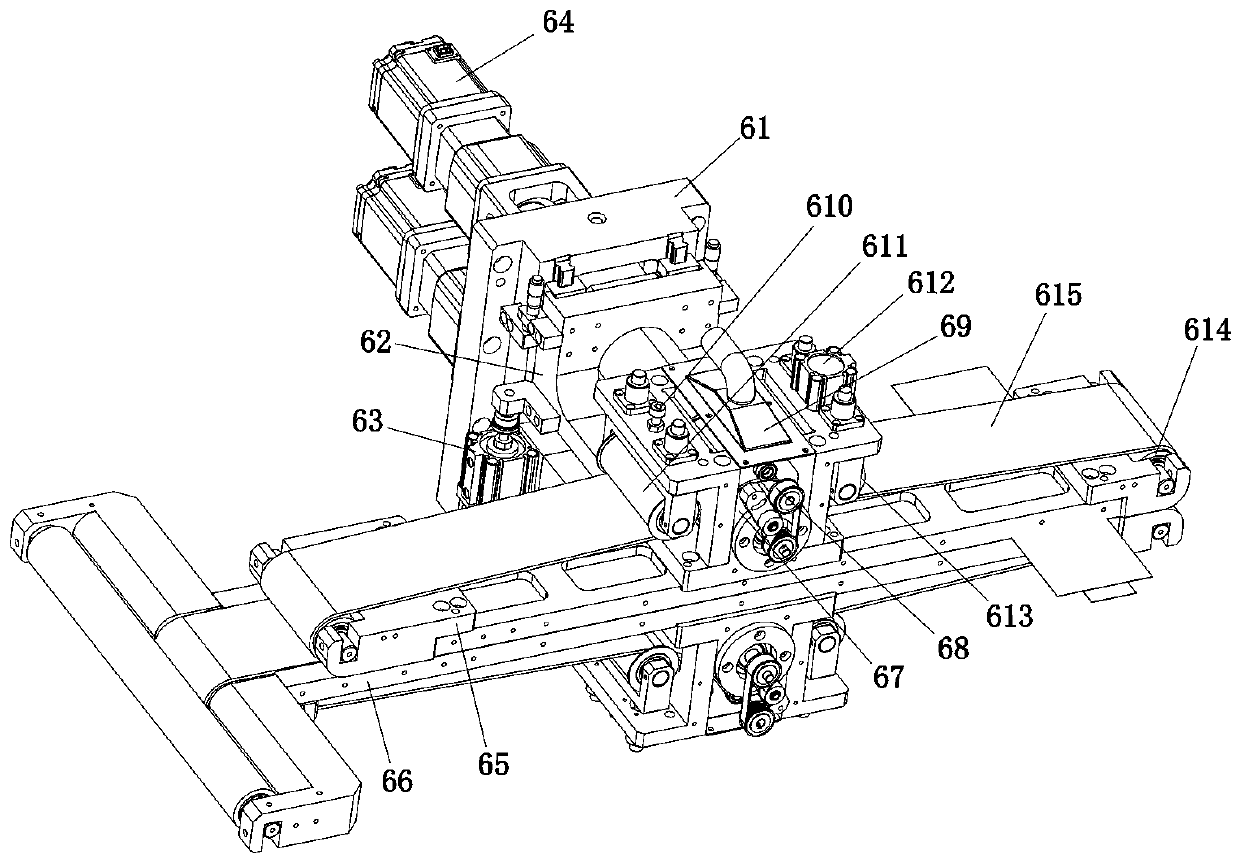

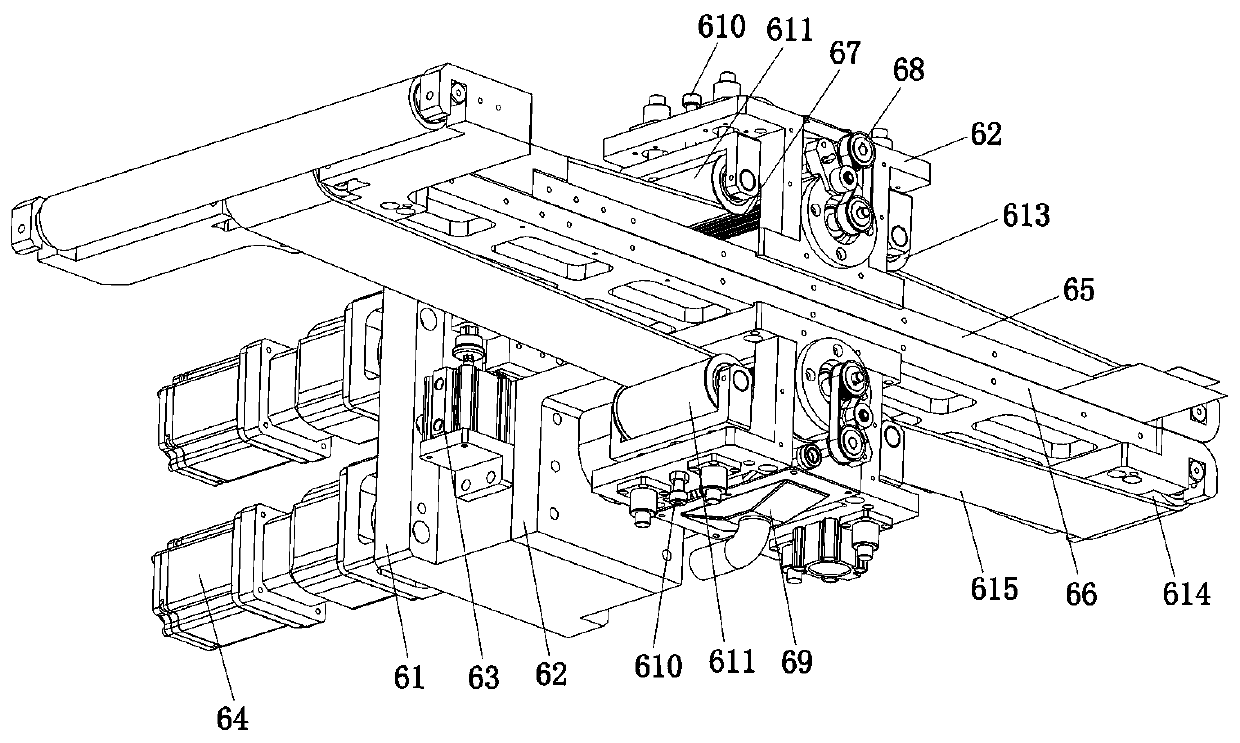

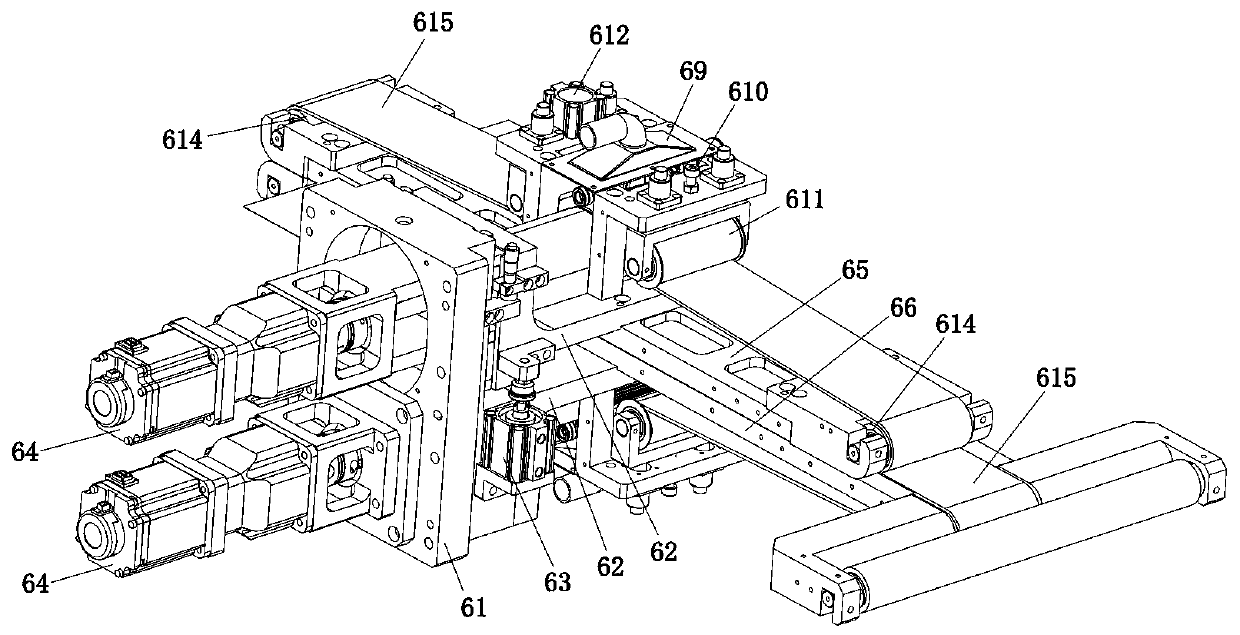

[0024] The present invention will be further described below in conjunction with accompanying drawing:

[0025] Such as Figure 1 to Figure 5As shown, the technical solution adopted by the present invention is as follows: a synchronous traction and bonding device for pole pieces and separators, including a traction and lamination support 61, a traction and lamination platform and a traction and lamination assembly, wherein the traction and lamination support 61 is set vertically; the traction lamination platform is horizontally connected to the side wall of the traction lamination support 61, the traction lamination platform is provided with a horizontal first traction lamination surface, and the first traction lamination surface is covered with The traction conveyor belt moves linearly along the first traction and bonding surface, and simultaneously cleans the surface and removes dust through the cleaning and dust removal components arranged on the back of the traction and bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com