Electric connector and manufacturing method thereof

A technology for electrical connectors and manufacturing methods, which is applied in the field of electrical connectors and its manufacturing, and can solve problems such as reducing the transmission rate of signal terminals, deviating from a predetermined position of a terminal row, and weak connection of an insulating body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

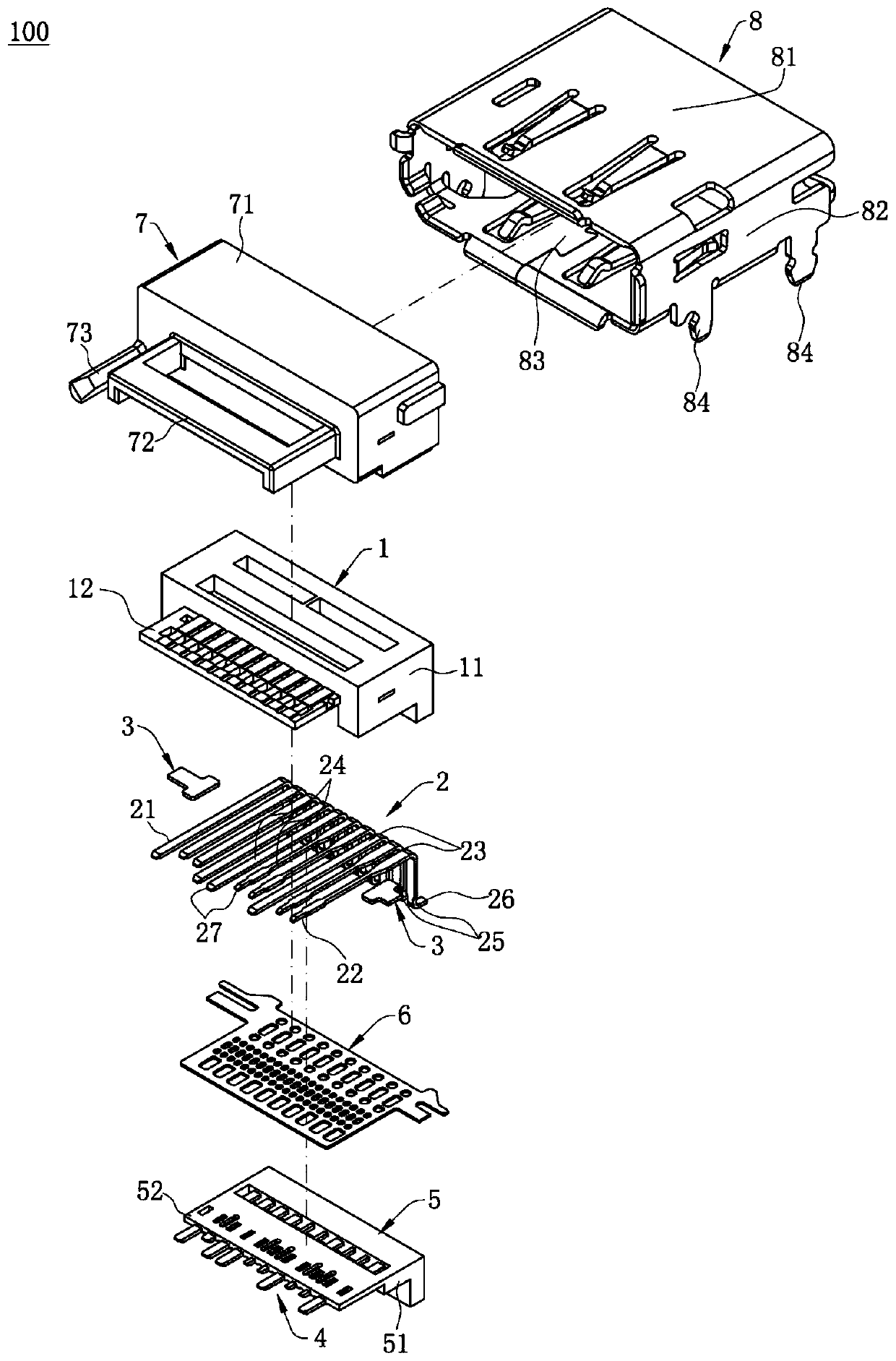

[0047] Such as figure 2 Shown is the first embodiment of the present invention: an electrical connector 100 for installing on a circuit board (not shown) to transmit high-frequency signals, the electrical connector 100 is a DP electrical connector, The electrical connector 100 mainly includes a first terminal row 2 embedded in an insulating body 1, a connector 3 and a shielding sheet 6, a second terminal row 4 embedded in an insulating seat 5, An insulating shell 7 formed on the insulating body 1 and the insulating base 5 and a shielding shell 8 wrapped on the insulating shell 7 .

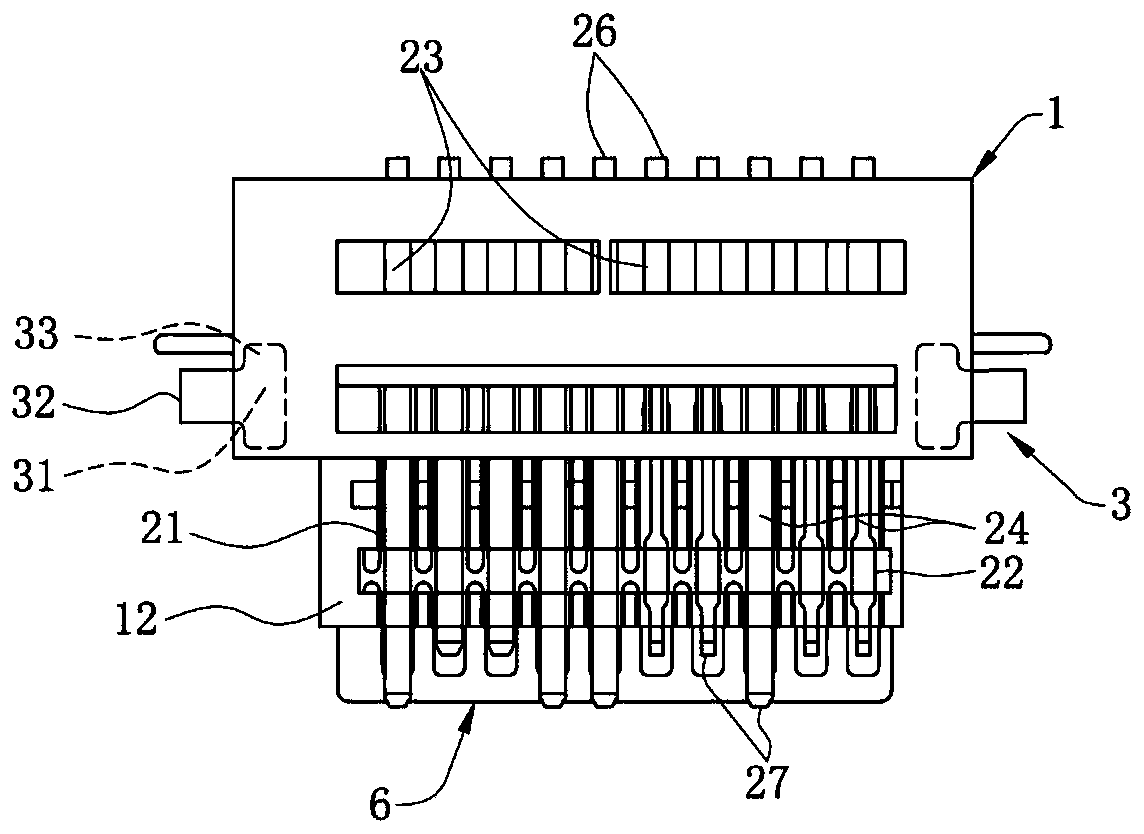

[0048] Specifically, such as image 3 with 4 As shown, the insulating body 1 is mainly made of plastic material and includes a rectangular base 11 and a first tongue 12 extending forward from the front end of the base 11. The insulating body 1 is injection molded The way is molded on the first terminal row 2 .

[0049] Such as figure 2 , image 3 , Figure 4 As shown, the first terminal bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com