A pulverizer for building materials production

A pulverizer and building material technology, applied in the direction of grain processing, etc., can solve the problems that the material cannot be used directly, the material cannot be fully utilized, and the quality of the material is degraded, so as to prevent random opening, improve the pulverization effect, and reduce waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

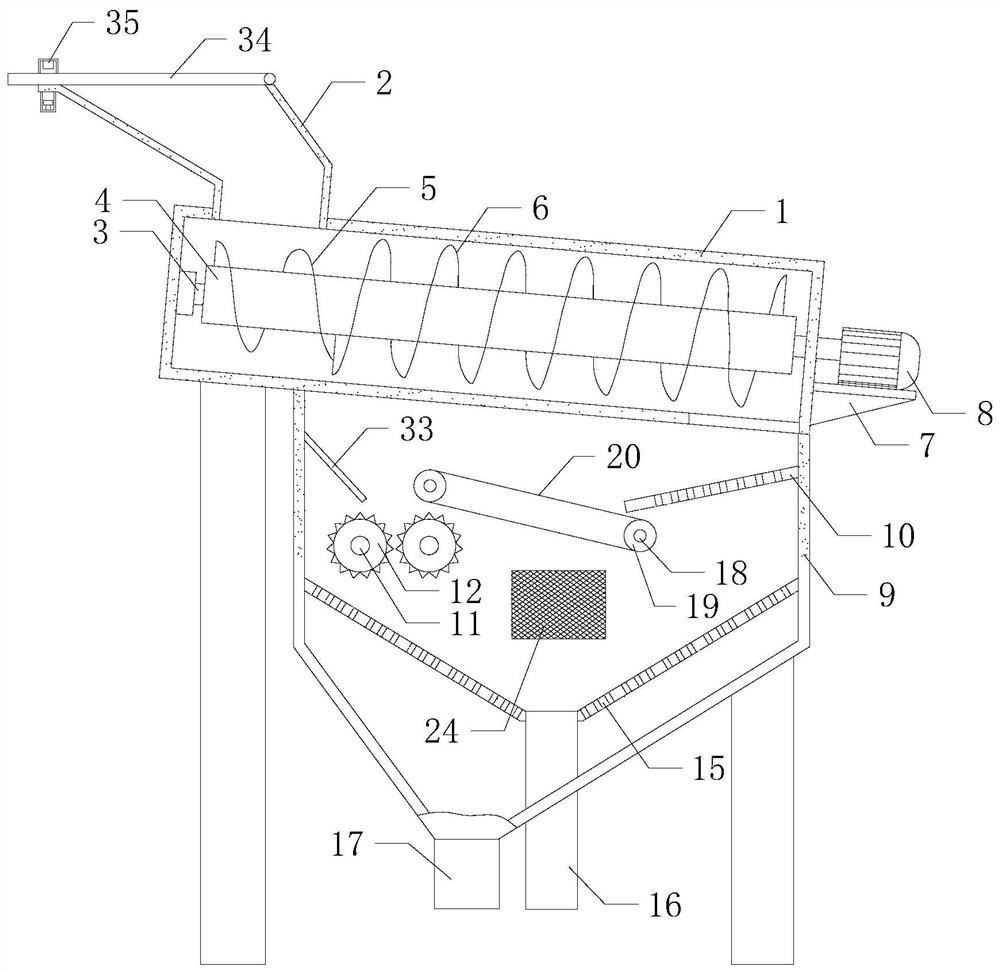

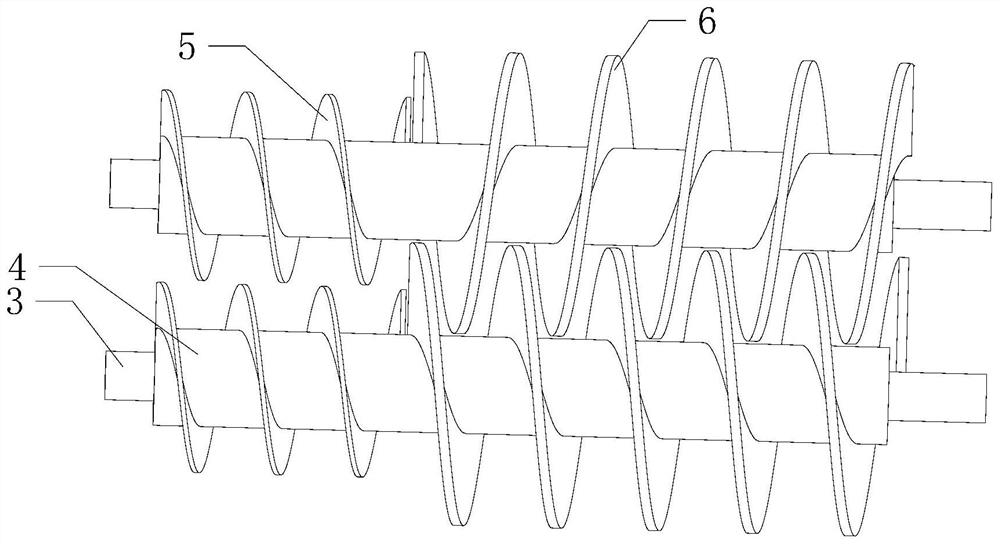

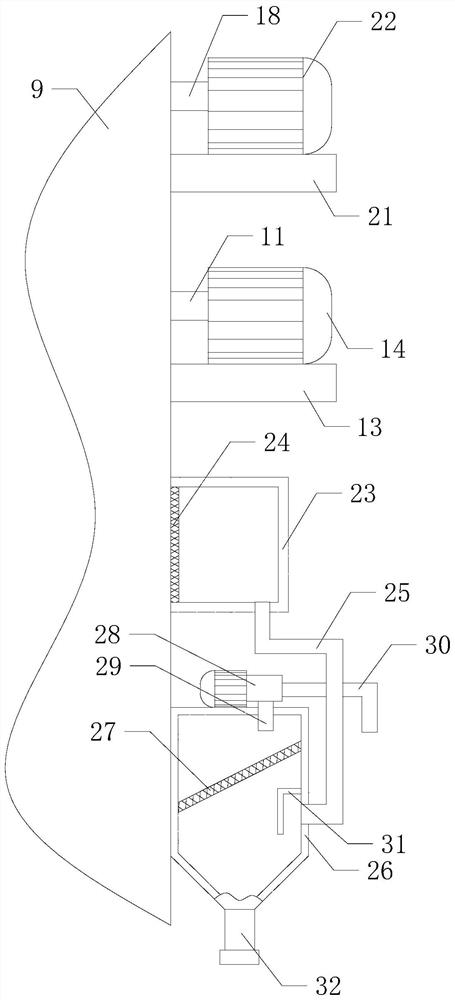

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0023] Such as Figure 1 to Figure 4 As shown, a pulverizer for building materials production according to the present invention, when it is working, opens the first pulverizing device and the second pulverizing device, sends external building materials into the first pulverizing device for primary pulverization, and the primary pulverized materials Enter the second crushing device for secondary crushing, and at the same time, the second crushing device sorts the materials, and the sorted dusty materials and small particle materials are respectively discharged into the external collection device.

[0024] The main functions realized by the present invention are: by settin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com